UX/UI Design Case Study

Manufacturing Management

UX/UI Design Case Study

Manufacturing Management

UX/UI Design Case Study

Manufacturing Management

UX/UI Design Case Study

Manufacturing Management

SERVICES:

Research & Design

TARGET PLATFORM:

Responsive Web App

LOCATION & YEAR:

London, 2023/24

SERVICES:

Research & Design

TARGET PLATFORM:

Responsive Web App

LOCATION & YEAR:

London, 2023/24

SERVICES:

Research & Design

TARGET PLATFORM:

Responsive Web App

LOCATION & YEAR:

London, 2023/24

SERVICES:

Research & Design

TARGET PLATFORM:

Responsive Web App

LOCATION & YEAR:

London, 2023/24

A Story of Smooth Evolution

A Story of Smooth Evolution

A Story of Smooth Evolution

A Story of Smooth Evolution

Here's how I've helped my client revitalise their management platform - MMS - restoring it to optimal performance, putting an end to traffic decline, and streamlining work processes for a significantly smoother and more efficient experience.

Here's how I've helped my client revitalise their management platform - MMS - restoring it to optimal performance, putting an end to traffic decline, and streamlining work processes for a significantly smoother and more efficient experience.

Here's how I've helped my client revitalise their management platform - MMS - restoring it to optimal performance, putting an end to traffic decline, and streamlining work processes for a significantly smoother and more efficient experience.

PROBLEM

PROBLEM

PROBLEM

PROBLEM

01

01

01

01

Alex Turner.

Alex Turner.

Alex Turner.

Client

Client

Client

The client faced a challenge, with communication methods between teams, which resulted in delays and inefficiencies. Emails and phone calls were not effective enough in sharing updates among factories and sites scattered across different locations. The need for an real time communication system was pressing.

The client faced a challenge, with communication methods between teams, which resulted in delays and inefficiencies. Emails and phone calls were not effective enough in sharing updates among factories and sites scattered across different locations. The need for an real time communication system was pressing.

The client faced a challenge, with communication methods between teams, which resulted in delays and inefficiencies. Emails and phone calls were not effective enough in sharing updates among factories and sites scattered across different locations. The need for an real time communication system was pressing.

The problem the client came to me with

The problem the client came to me with

The problem the client

came to me with

Reversing a decline in traffic and streamlining operations for their management platform - MMS.

Reversing a decline in traffic and streamlining operations for their management platform - MMS.

Reversing a decline in traffic and streamlining operations for their management platform - MMS.

Who Are Our Users?

Who Are Our Users?

John Snow

John Snow

John Snow

Factory Planner

Factory Planner

Factory Planner

John Snow is a Factory Planner who specializes in the construction industry. His main duties encompass optimizing production schedules effectively overseeing steel orders and maintaining lines of communication, with site managers to fulfill order requirements and handle any modifications.

John Snow is a Factory Planner who specializes in the construction industry. His main duties encompass optimizing production schedules effectively overseeing steel orders and maintaining lines of communication, with site managers to fulfill order requirements and handle any modifications.

John Snow is a Factory Planner who specializes in the construction industry. His main duties encompass optimizing production schedules effectively overseeing steel orders and maintaining lines of communication, with site managers to fulfill order requirements and handle any modifications.

Catelyn Brown

Catelyn Brown

Catelyn Brown

Site Manager

Site Manager

Site Manager

Catelyn Brown is a Site Manager. Catelyn’s role involves collaborating with the factory to acquire construction elements for her projects and ensuring their delivery to the site. To facilitate this she seeks an user friendly process for placing orders for construction elements, from the factory.

Catelyn Brown is a Site Manager. Catelyn’s role involves collaborating with the factory to acquire construction elements for her projects and ensuring their delivery to the site. To facilitate this she seeks an user friendly process for placing orders for construction elements, from the factory.

Catelyn Brown is a Site Manager. Catelyn’s role involves collaborating with the factory to acquire construction elements for her projects and ensuring their delivery to the site. To facilitate this she seeks an user friendly process for placing orders for construction elements, from the factory.

Jason Carter

Jason Carter

Jason Carter

Quality Personnel

Quality Personnel

Quality Personnel

Jason Carter is a Quality Personnel responsible for overseeing the quality standards of construction elements, like columns, walls, beams, etc. His primary objective is to enforce rigorous quality control and assurance processes to meet industry benchmarks.

Jason Carter is a Quality Personnel responsible for overseeing the quality standards of construction elements, like columns, walls, beams, etc. His primary objective is to enforce rigorous quality control and assurance processes to meet industry benchmarks.

Jason Carter is a Quality Personnel responsible for overseeing the quality standards of construction elements, like columns, walls, beams, etc. His primary objective is to enforce rigorous quality control and assurance processes to meet industry benchmarks.

Emma Davies

Emma Davies

Emma Davies

Site Delivery Courier

Site Delivery Courier

Site Delivery Courier

Emma Davis takes charge of overseeing the delivery of construction elements from the factory to the construction site. Her main goal is to guarantee that materials are delivered by the deadline. As part of her responsibilities Emma works closely with teams such, as factory planners, site managers and quality personnel to efficiently organize and schedule deliveries.

Emma Davis takes charge of overseeing the delivery of construction elements from the factory to the construction site. Her main goal is to guarantee that materials are delivered by the deadline. As part of her responsibilities Emma works closely with teams such, as factory planners, site managers and quality personnel to efficiently organize and schedule deliveries.

Emma Davis takes charge of overseeing the delivery of construction elements from the factory to the construction site. Her main goal is to guarantee that materials are delivered by the deadline. As part of her responsibilities Emma works closely with teams such, as factory planners, site managers and quality personnel to efficiently organize and schedule deliveries.

DISCOVERY

DISCOVERY

DISCOVERY

DISCOVERY

02

02

02

02

“It would be much easier if there was a streamlined process to request construction elements without relying on manual emails 😒.”

“It would be much easier if there was a streamlined process to request construction elements without relying on manual emails 😒.”

“We need better visibility into the status of our orders 😟 .”

“We need better visibility into the status of our orders 😟 .”

“Ordering steel is a nightmare. Having to send all those excel files via email for checks is very time-consuming process. 🙁 🙁”

“Ordering steel is a nightmare. Having to send all those excel files via email for checks is very time-consuming process. 🙁 🙁”

“Ordering steel is a nightmare. Having to send all those excel files via email for checks is very time-consuming process. 🙁 🙁”

We’ve conducted a interviews amongs the construction workers to find out their pains

Based on the survey results, we’ve made a list of users needs

Based on the survey results, we’ve made a list of users needs

Based on the survey results, we’ve made a list of users needs

Order placement process for requesting specific construction elements from the factory. Real-time tracking and updates on the status and progress of the orders within the platform.

Automated production scheduling, considering available resources and delivery timelines.

Efficient steel management

An integrated quality control module to manage inspections and checks at various production stages.

Real-time updates on inspection results and the ability to add comments or photos to document findings.

Ability to scrap selected units ( if there is something wrong with it ) and restart the production of it.

A delivery tracking feature to manage delivery schedules, update delivery statuses, and mark when items are delivered.

"Dealing with the current system that can't handle drawing revisions is a major hussle. Whenever there are changes, it throws a wrench in the production process, causing delays and potentially costly errors 😓 😓 . "

"Dealing with the current system that can't handle drawing revisions is a major hussle. Whenever there are changes, it throws a wrench in the production process, causing delays and potentially costly errors 😓 😓 . "

"Dealing with the current system that can't handle drawing revisions is a major hussle. Whenever there are changes, it throws a wrench in the production process, causing delays and potentially costly errors 😓 😓 . "

We’ve conducted a survey amongs the construction workers to find out their pains

Based on the survey results, we’ve made a list of users needs

Order placement process for requesting specific construction elements from the factory.

Automated production scheduling.

Efficient steel management.

An integrated quality control.

Real-time updates on inspection results.

Ability to scrap selected units.

A delivery tracking feature.

Images

Approval

Comments

Order Status

Delivery Date&Time

Delivery Address

Block, Pour, Level

Quantity

Quantity

has 1 - many connections to Item

has 1 connection to Project

ORDER

ITEM/URN

Item Drawing

Naming Convention

Production Status

Item Type

Concrete Volume

Reinforcment Weight

has 1 connection to BBS

has 1 - many Quality Inspections

BBS

Naming Convention

Steel Order Status

Revision

Revision Status

Approver

Detailer

Total Weight

INSPECTION

Unit Drawing

Toolset

Quality Control Questions

Quality Status

has 1 connection to User

DELIVERY

Route Map

Driver Name

Delivery Contact Information

Pick Up location

has 1 connection to Order

has 1 connection to User

has 1 connection to Project

PROJECT

Job Number

Delivery Addresses

has 1 - many Users

WIREFRAMING

WIREFRAMING

02

02

01.

01.

01.

Define system’s objects: Order, Document, Inspection, Bar Bending Schedule, Delivery, Project

Define system’s objects: Order, Document, Inspection, Bar Bending Schedule, Delivery, Project

Define system’s objects: Order, Document, Inspection, Bar Bending Schedule, Delivery, Project

02.

02.

02.

Define correlation between all objects of the system.

Define correlation between all objects of the system.

Define correlation between all objects of the system.

03.

03.

03.

Build OOUX to get a complete pattern of the whole system.

Build OOUX to get a complete pattern of the whole system.

Build OOUX to get a complete pattern of the whole system.

Object mapping is really powerful

Object mapping is really powerful

Object mapping is really powerful

That’s what object-oriented UX is all about - thinking in terms of objects before actions.

That’s what object-oriented UX is all about - thinking in terms of objects before actions.

That’s what object-oriented UX is all about - thinking in terms of objects before actions.

Images

Approval

Comments

Order Status

Delivery Date&Time

Delivery Address

Block, Pour, Level

Quantity

has 1 - many connections to Item

has 1 connection to Project

ORDER

ITEM/URN

Item Drawing

Naming Convention

Production Status

Item Type

Concrete Volume

Reinforcment Weight

has 1 connection to BBS

has 1 - many Quality Inspections

WIREFRAMING

02

01.

Define system’s objects: Order, Document, Inspection, Bar Bending Schedule, Delivery, Project

02.

Define correlation between all objects of the system.

03.

Build OOUX to get a complete pattern of the whole system.

Object mapping is really powerful

That’s what object-oriented UX is all about - thinking in terms of objects before actions.

The client faced a challenge, with communication methods between teams, which resulted in delays and inefficiencies.

Emails and phone calls were not effective enough in sharing updates among factories and sites scattered across different locations.

The client faced a challenge, with communication methods between teams, which resulted in delays and inefficiencies.

Emails and phone calls were not effective enough in sharing updates among factories and sites scattered across different locations.

The client faced a challenge, with communication methods between teams, which resulted in delays and inefficiencies.

Emails and phone calls were not effective enough in sharing updates among factories and sites scattered across different locations.

The client faced a challenge, with communication methods between teams, which resulted in delays and inefficiencies.

Emails and phone calls were not effective enough in sharing updates among factories and sites scattered across different locations.

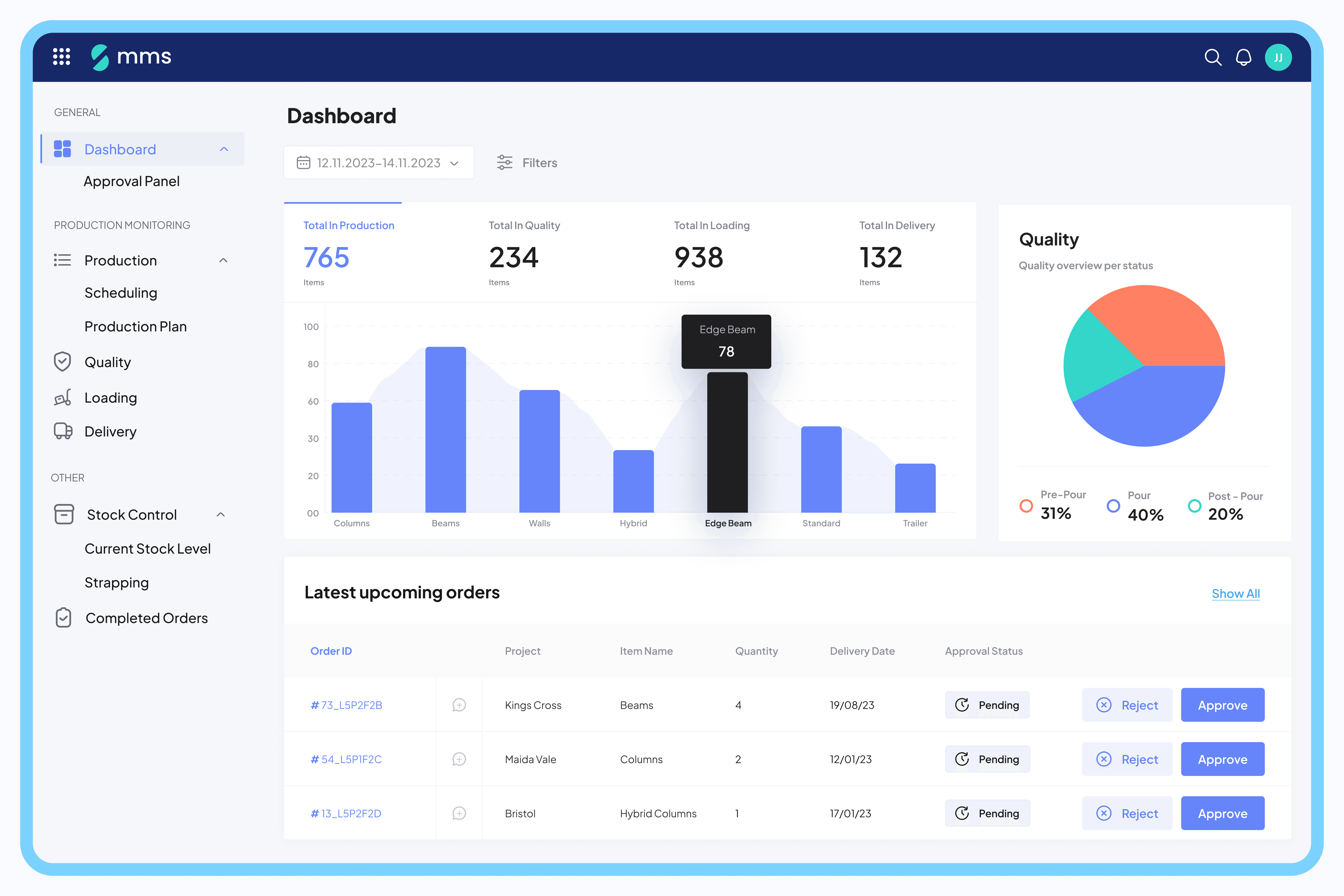

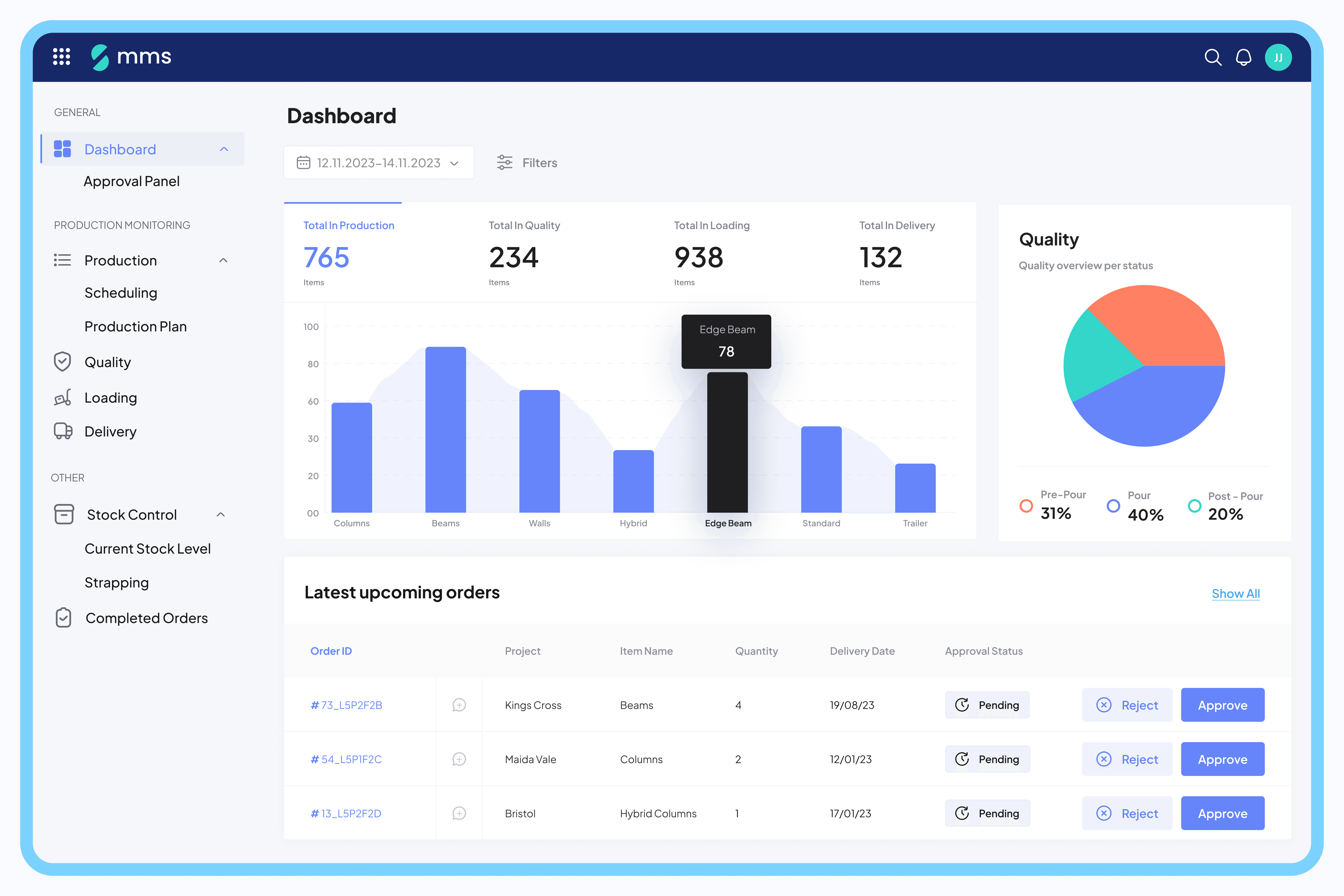

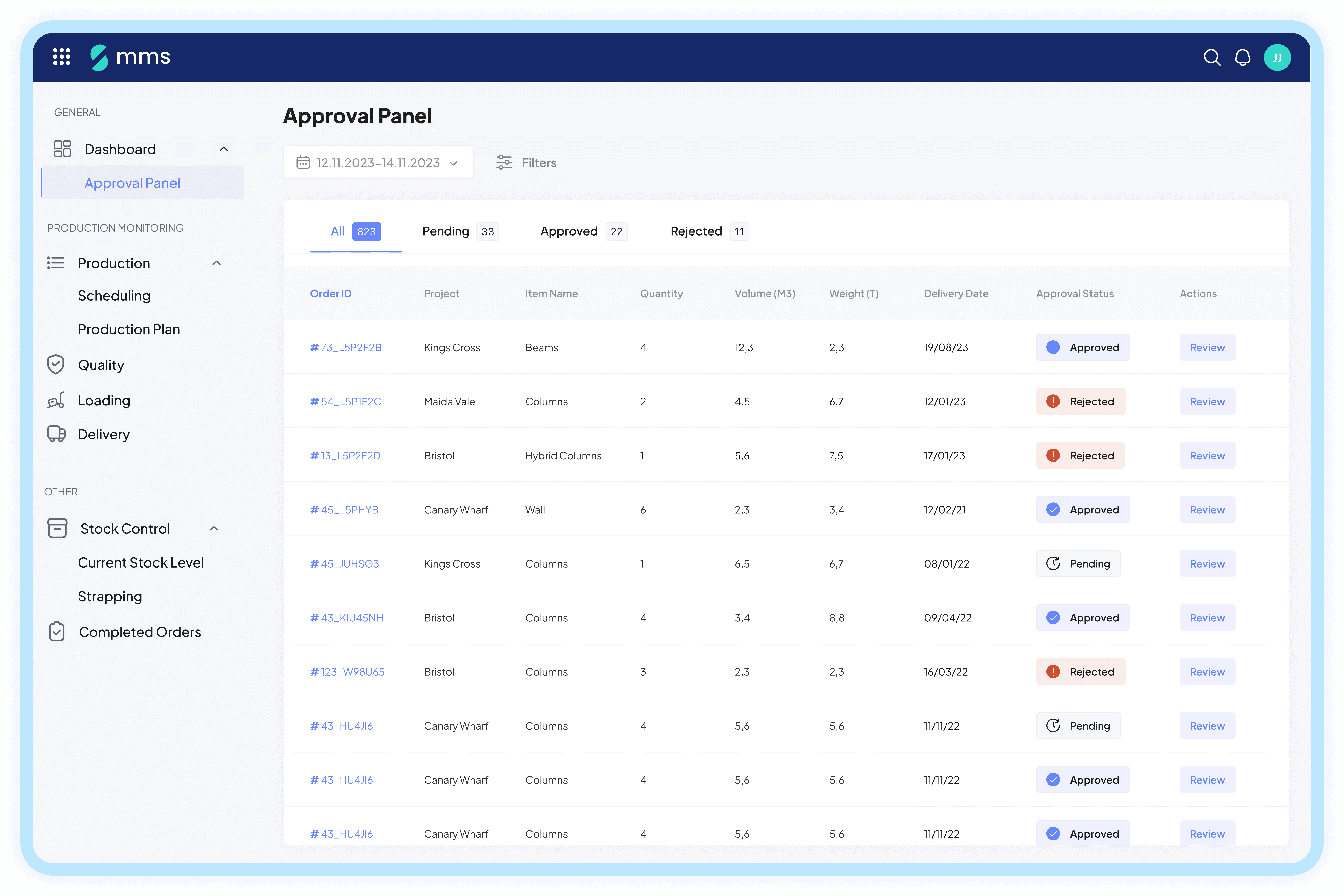

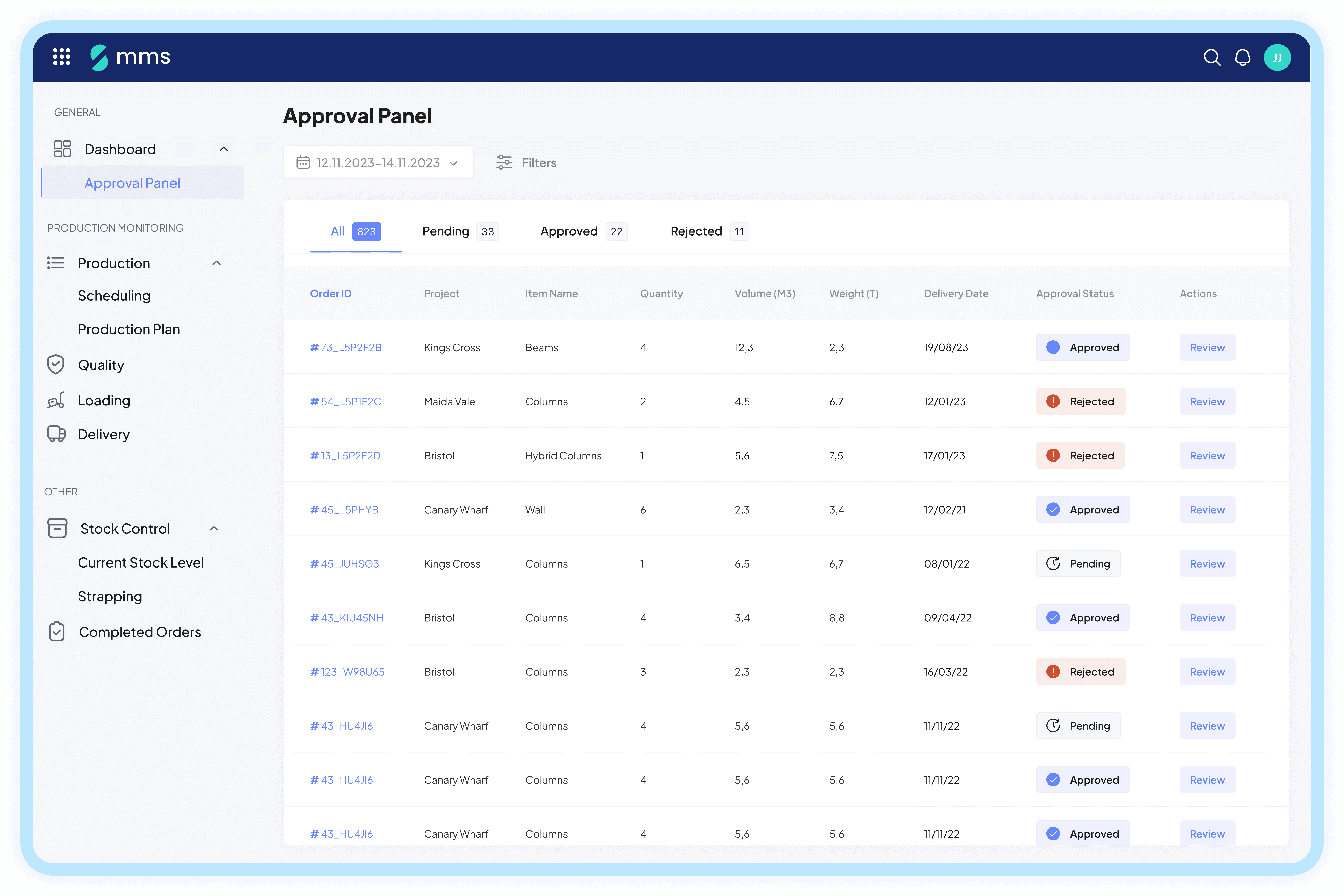

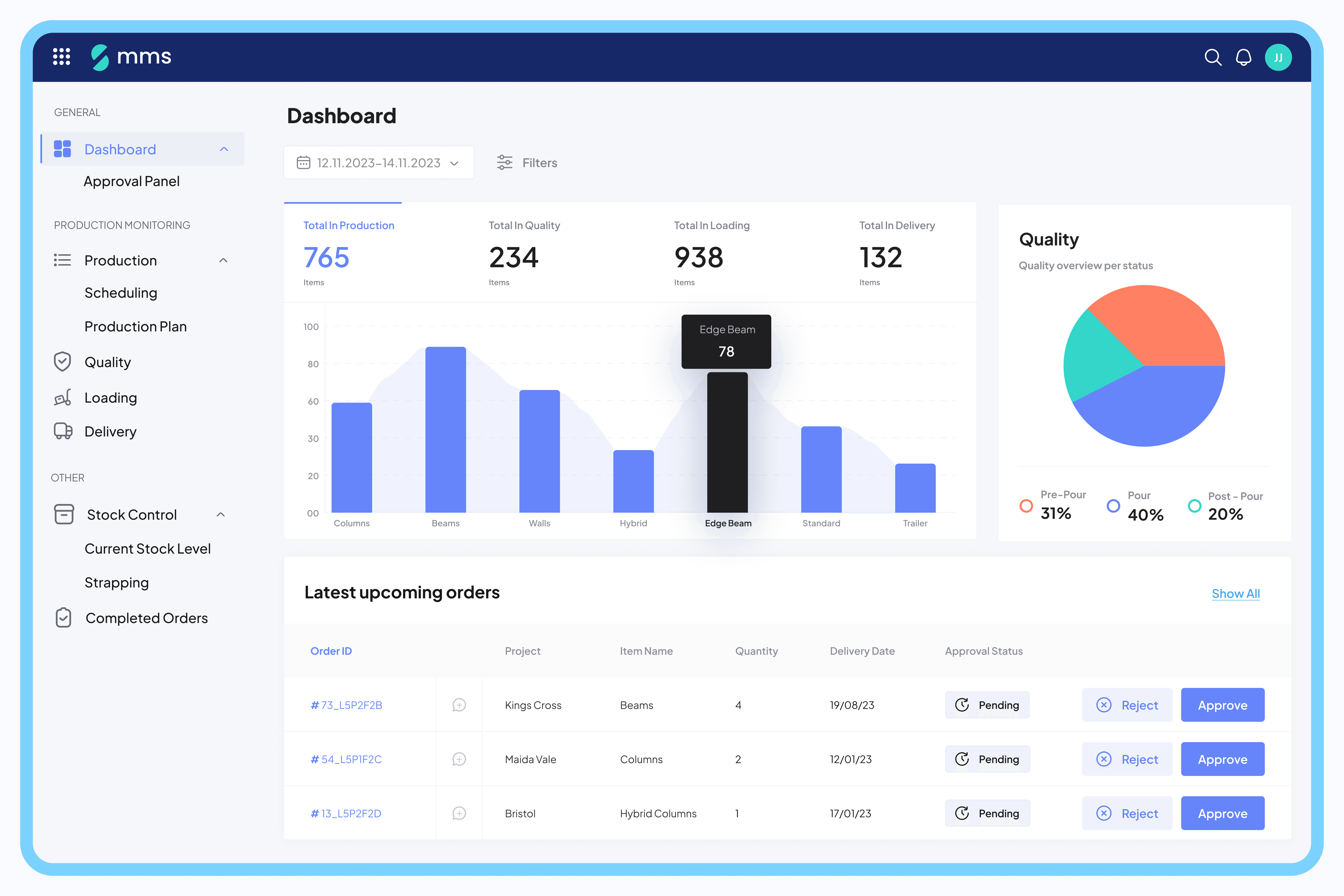

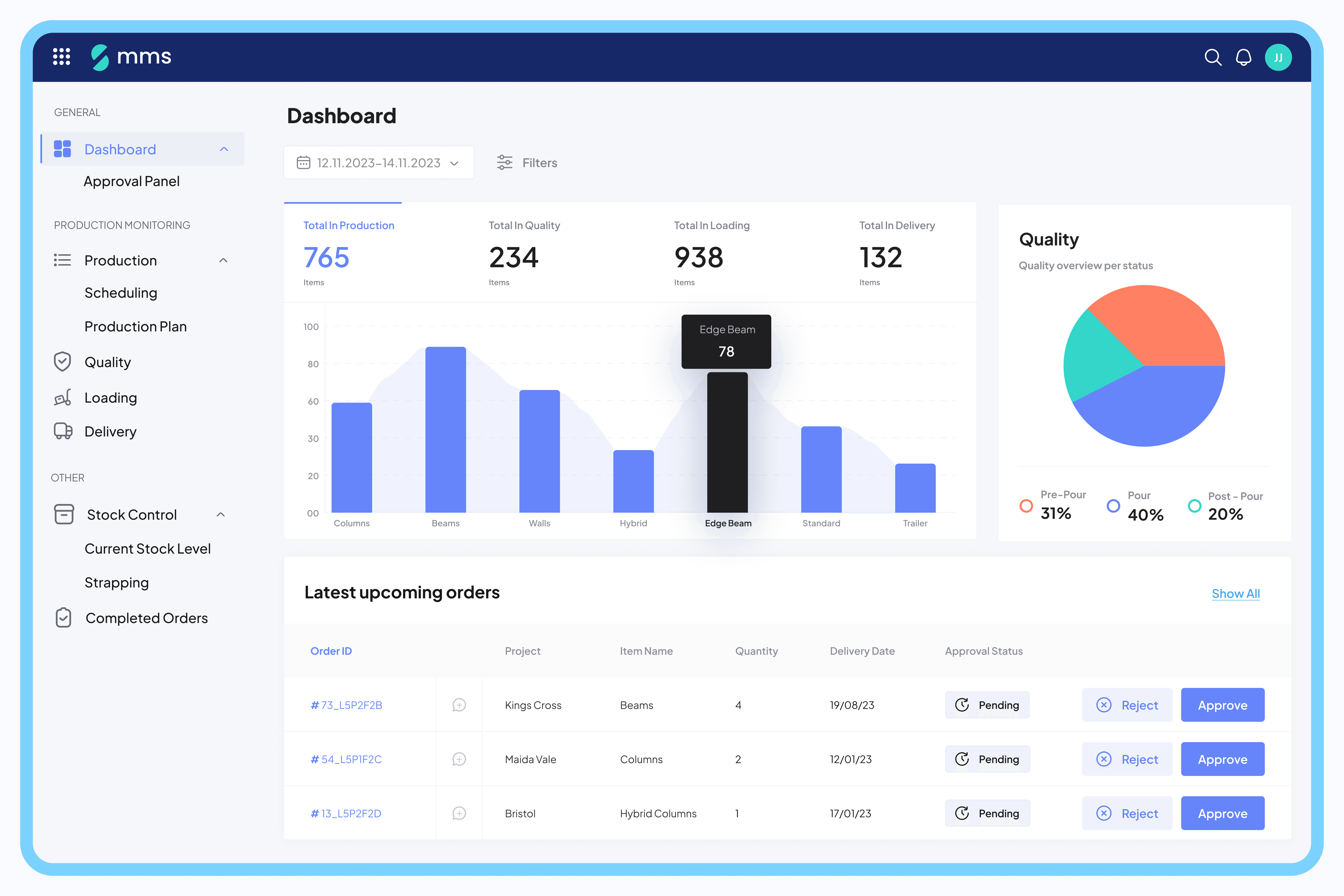

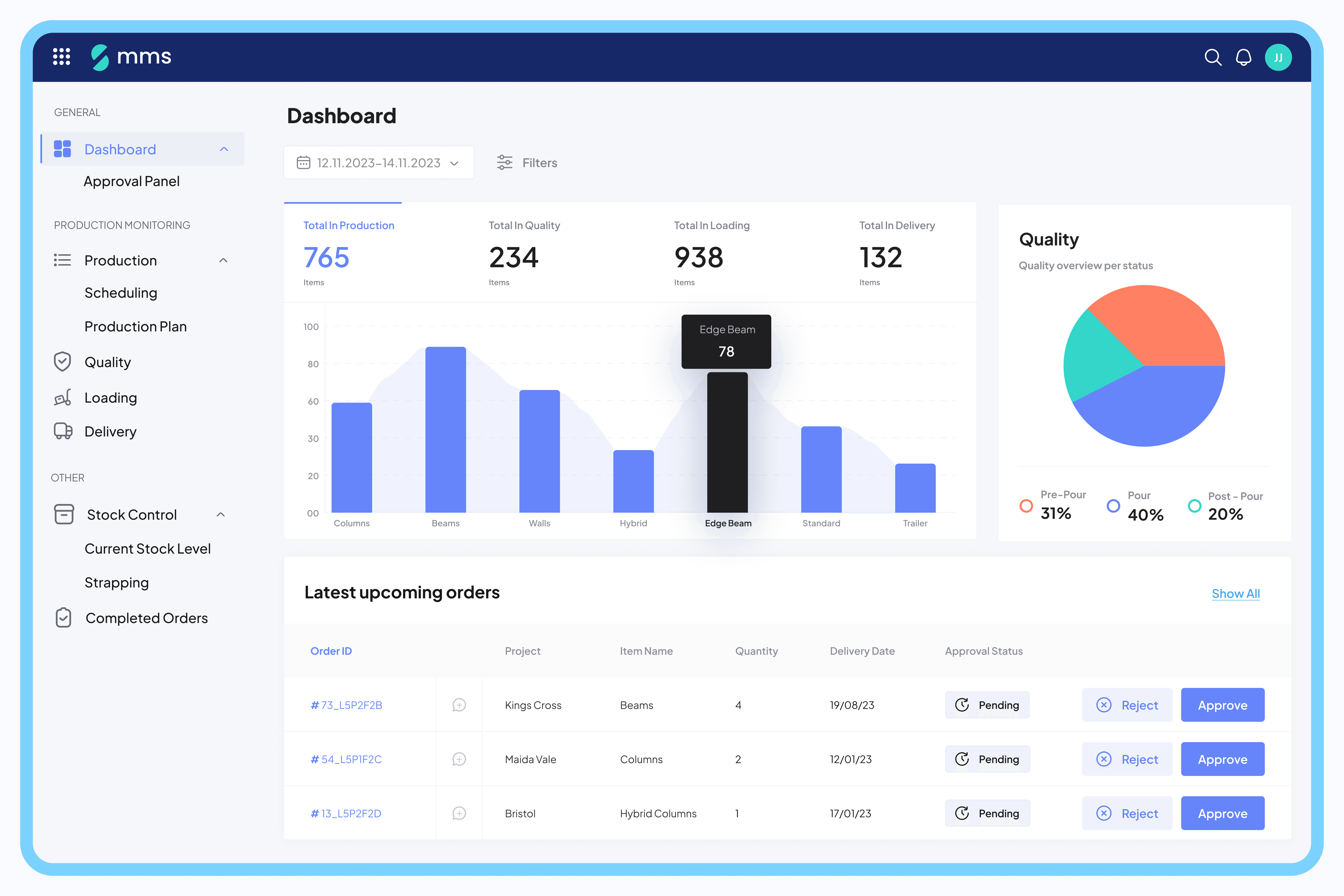

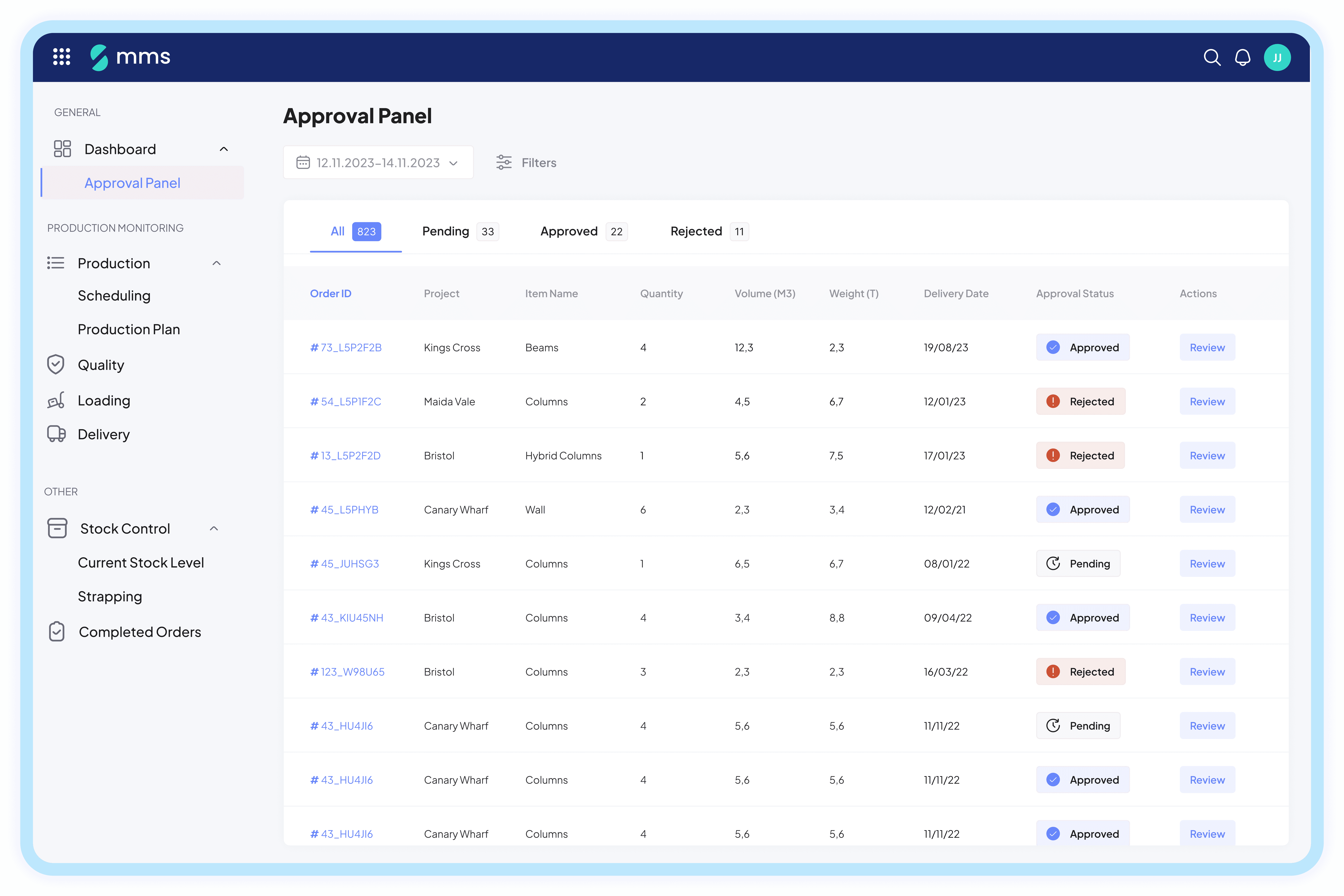

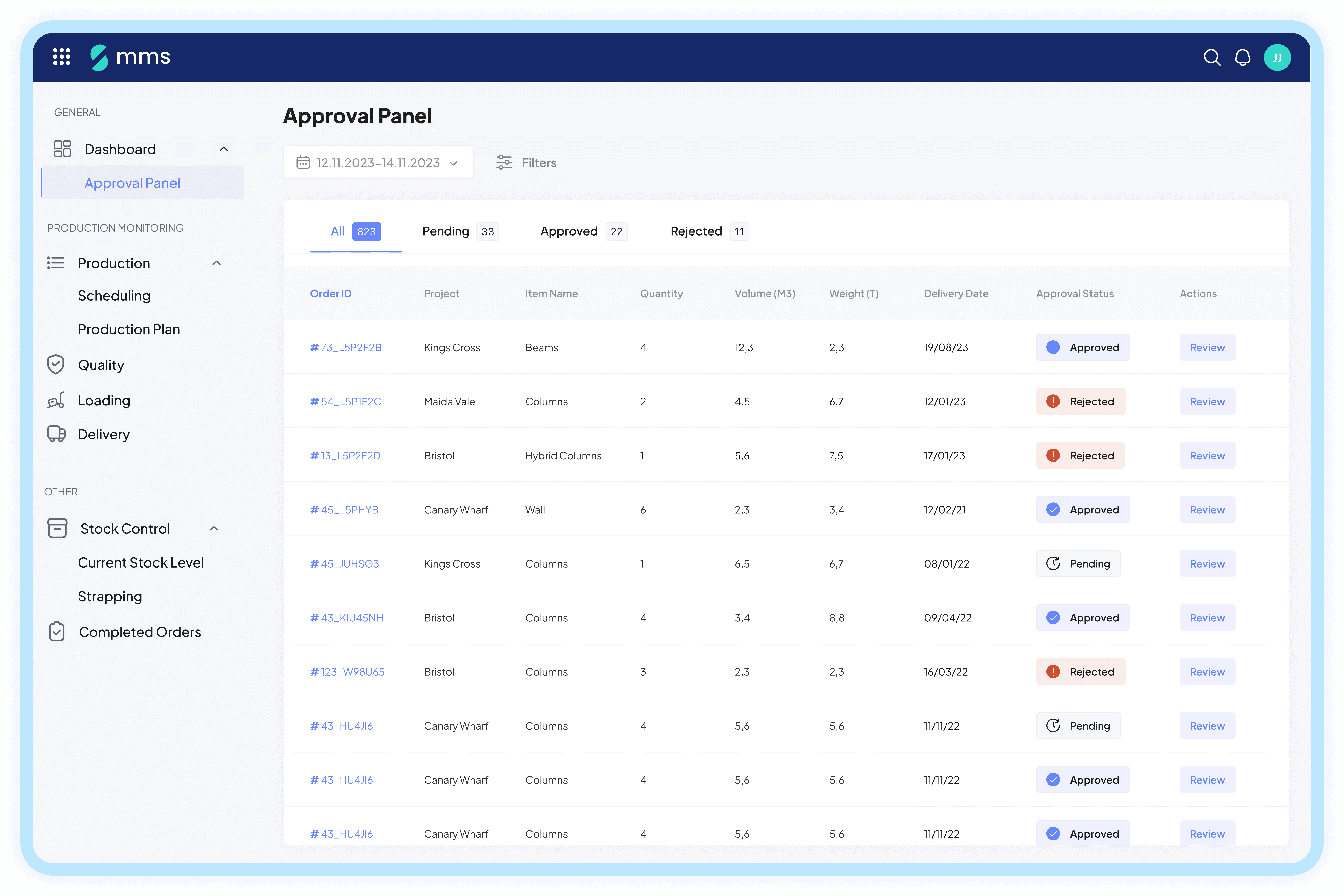

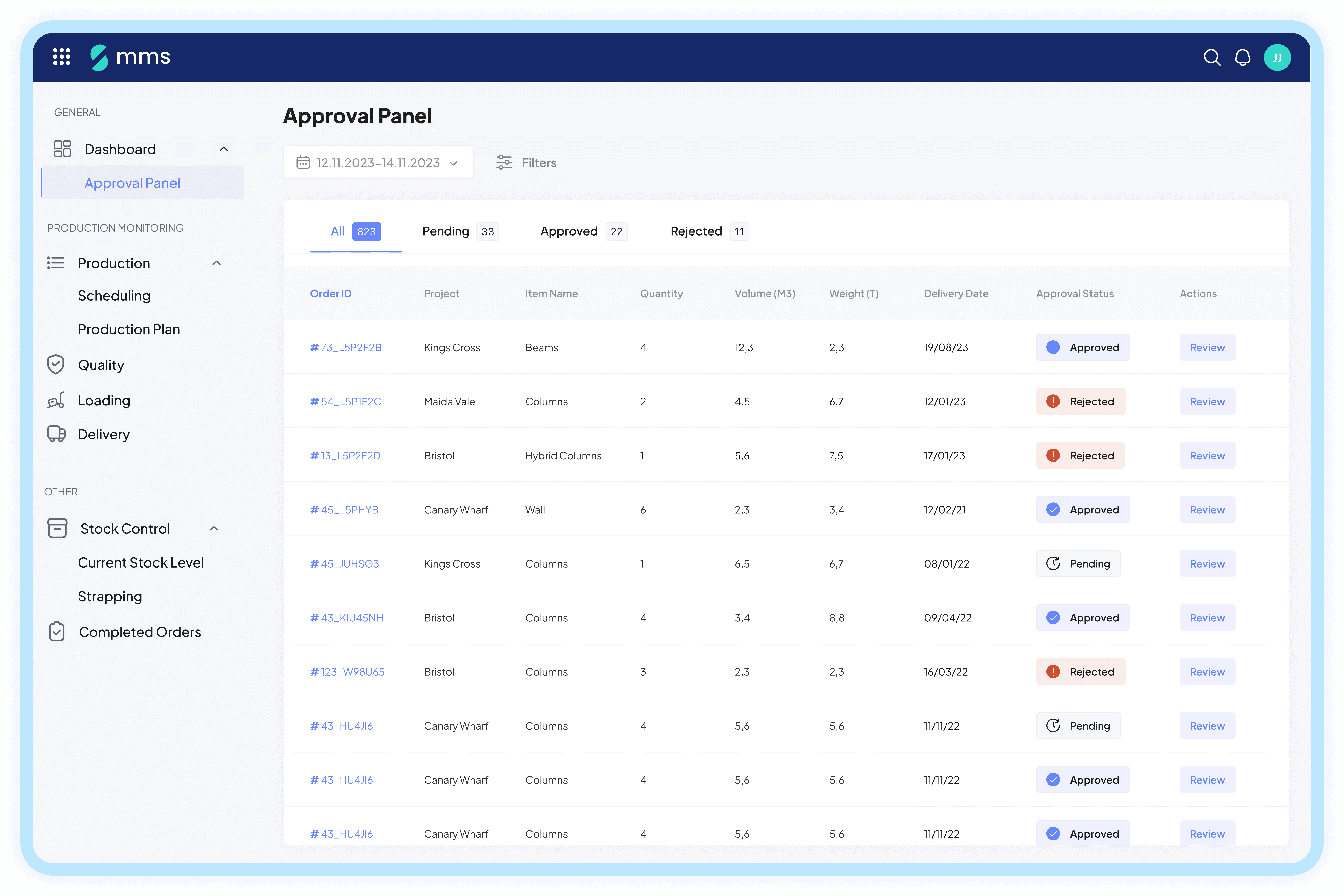

Dashboard

The dashboard enables users to access real-time data visualizations for each production stage and provides a quick overview of upcoming orders. Users can delve into detailed order descriptions, making informed decisions to approve or reject them.

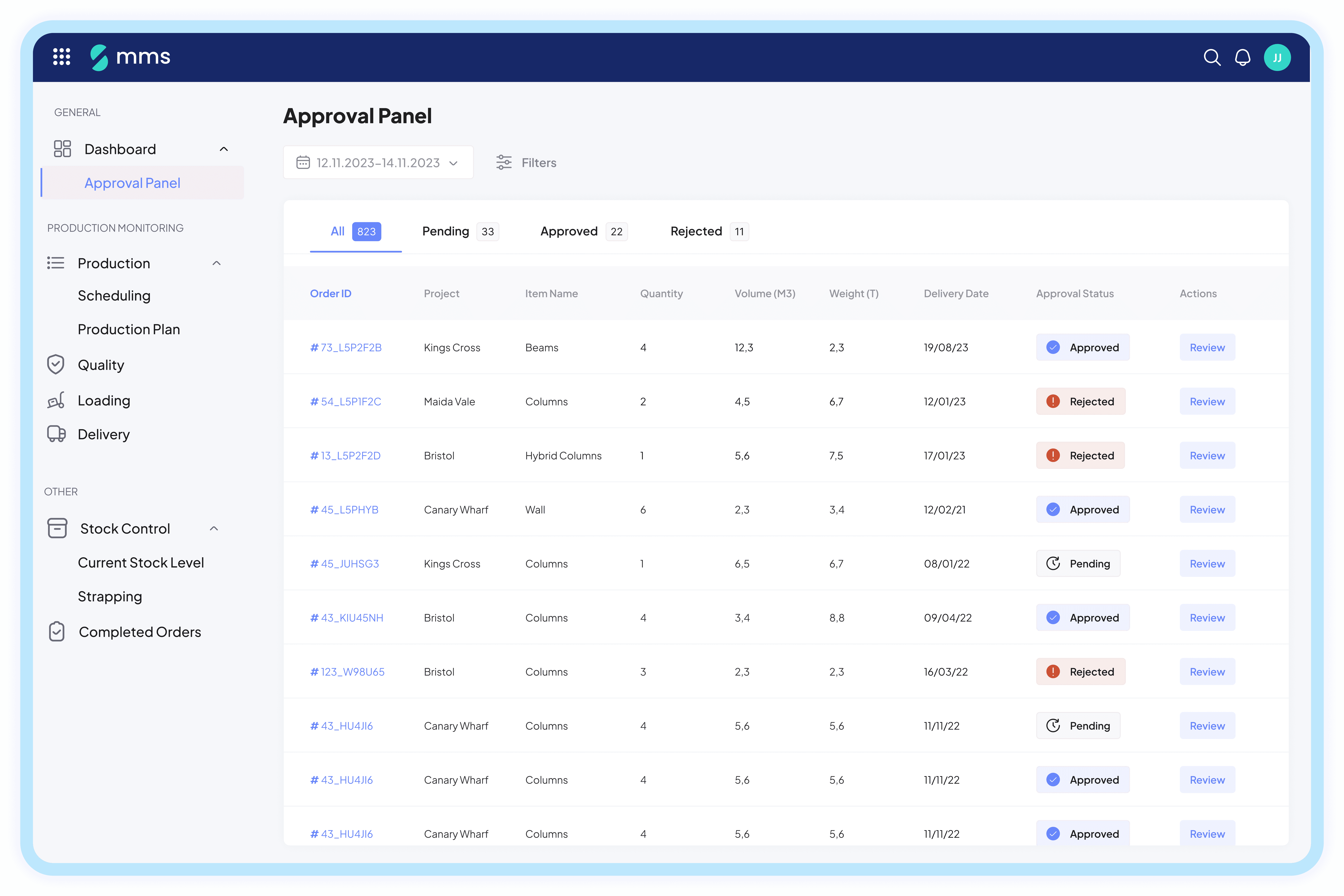

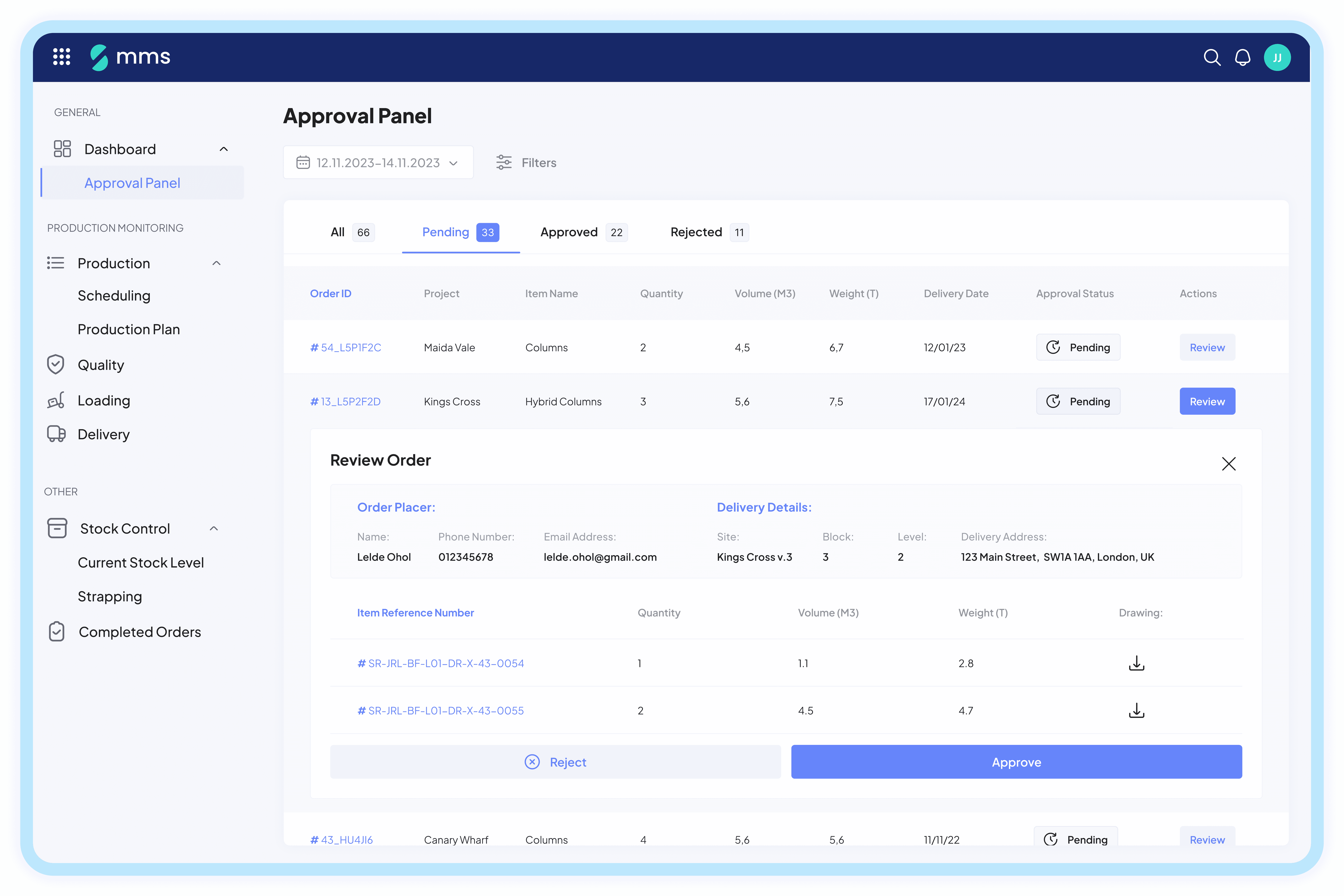

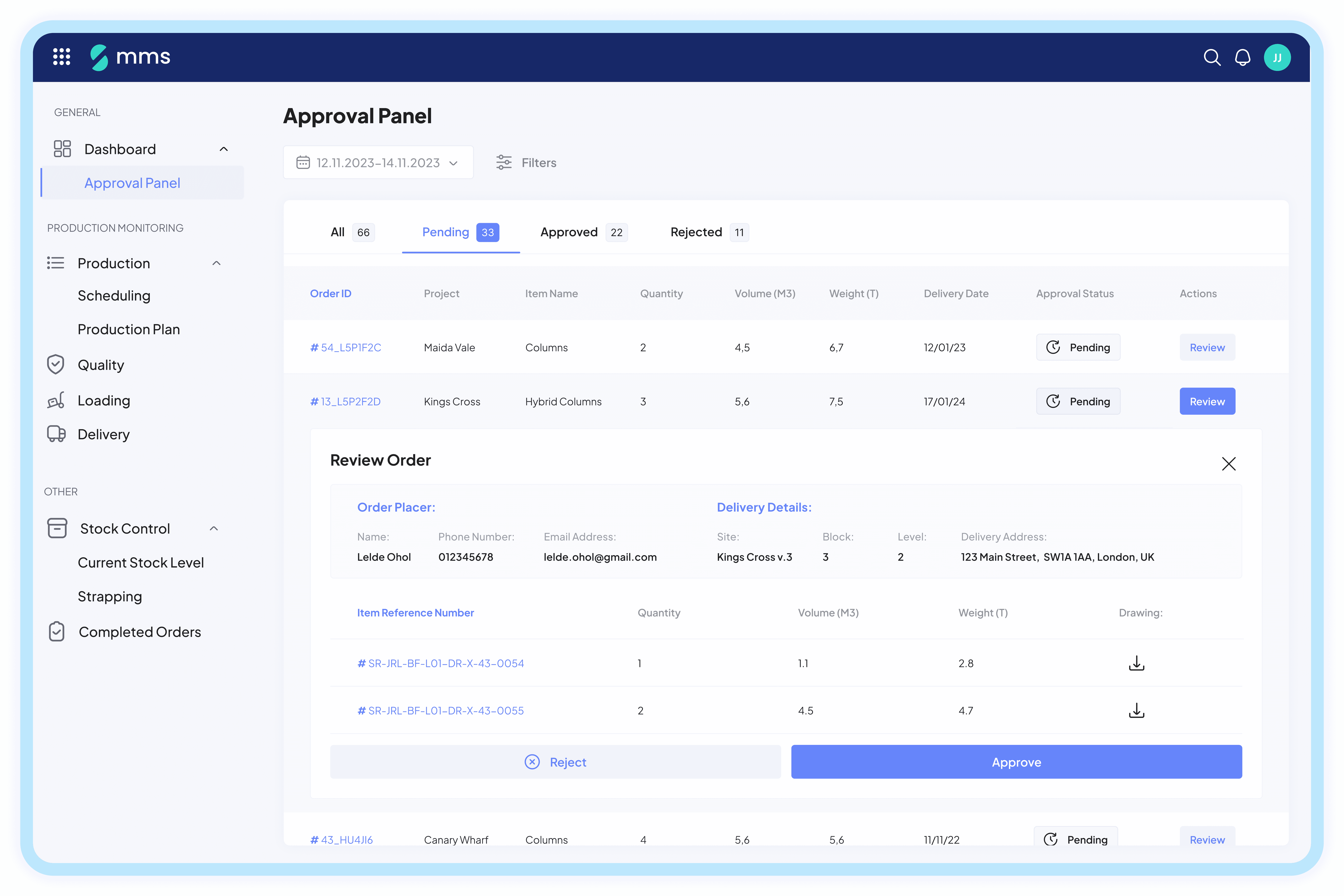

Approvals

Review upcoming orders, examining the number of items with associated volume and weight values. Additionally, assess delivery dates and reject orders when necessary, providing clear explanations directly to the site manager placing the order.

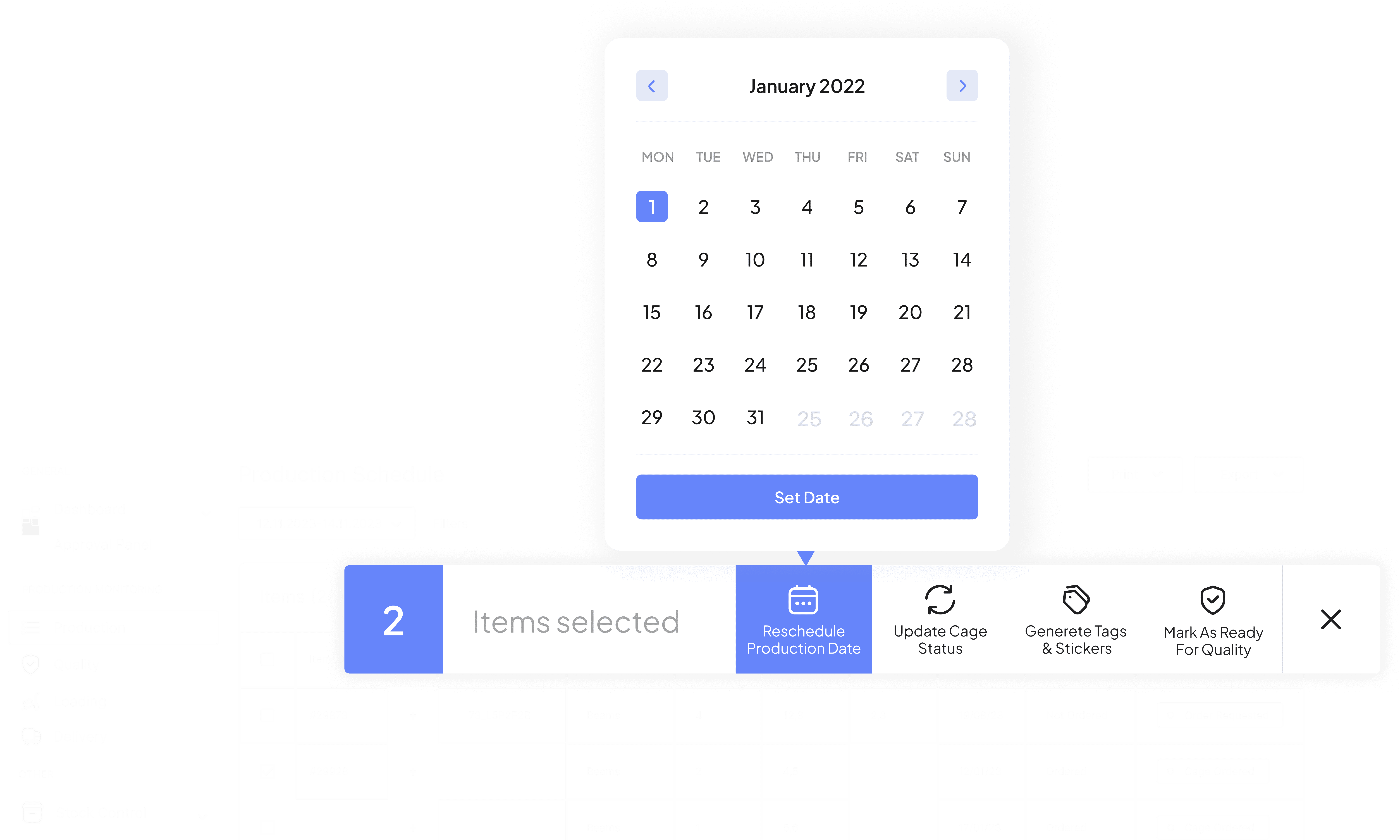

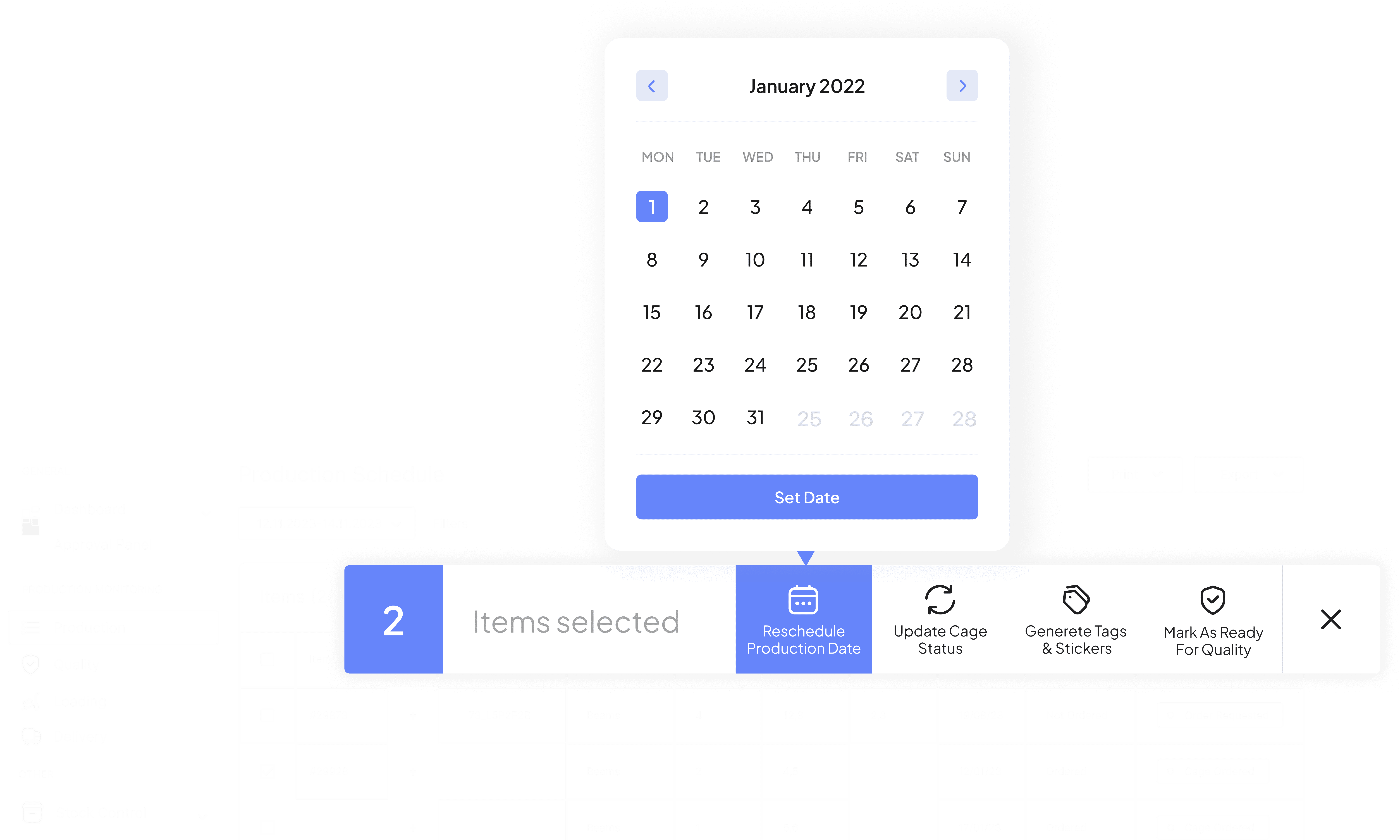

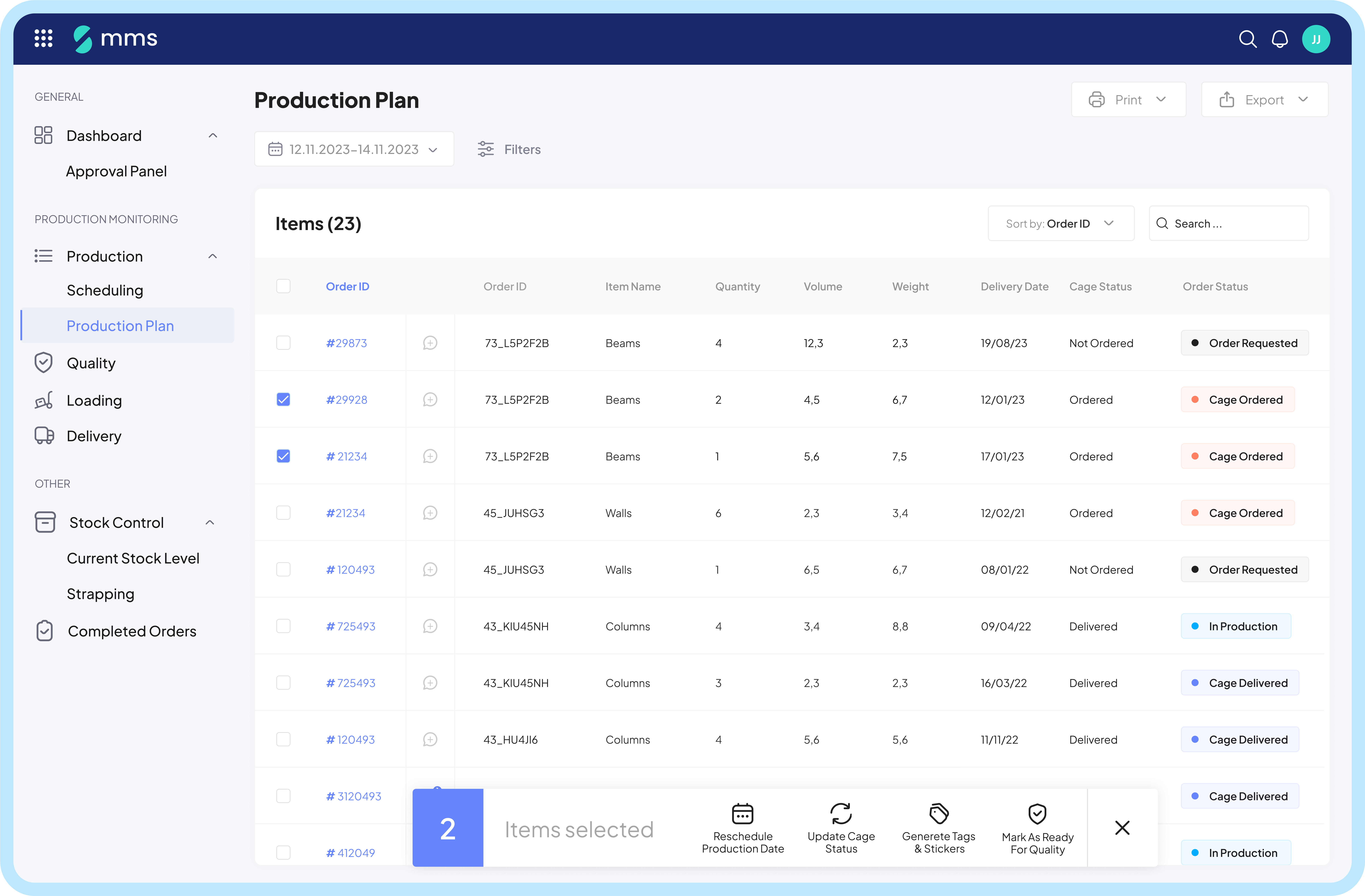

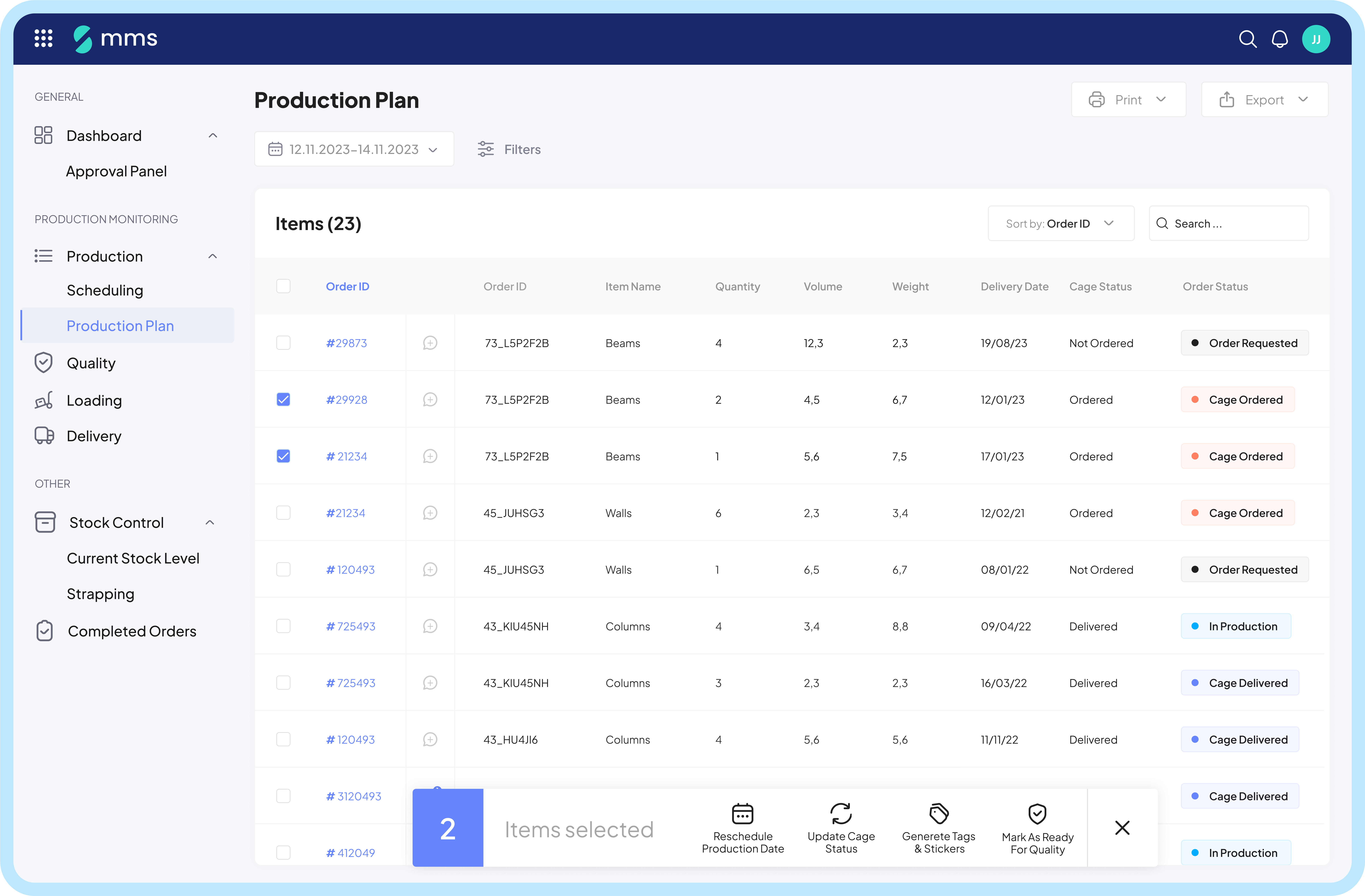

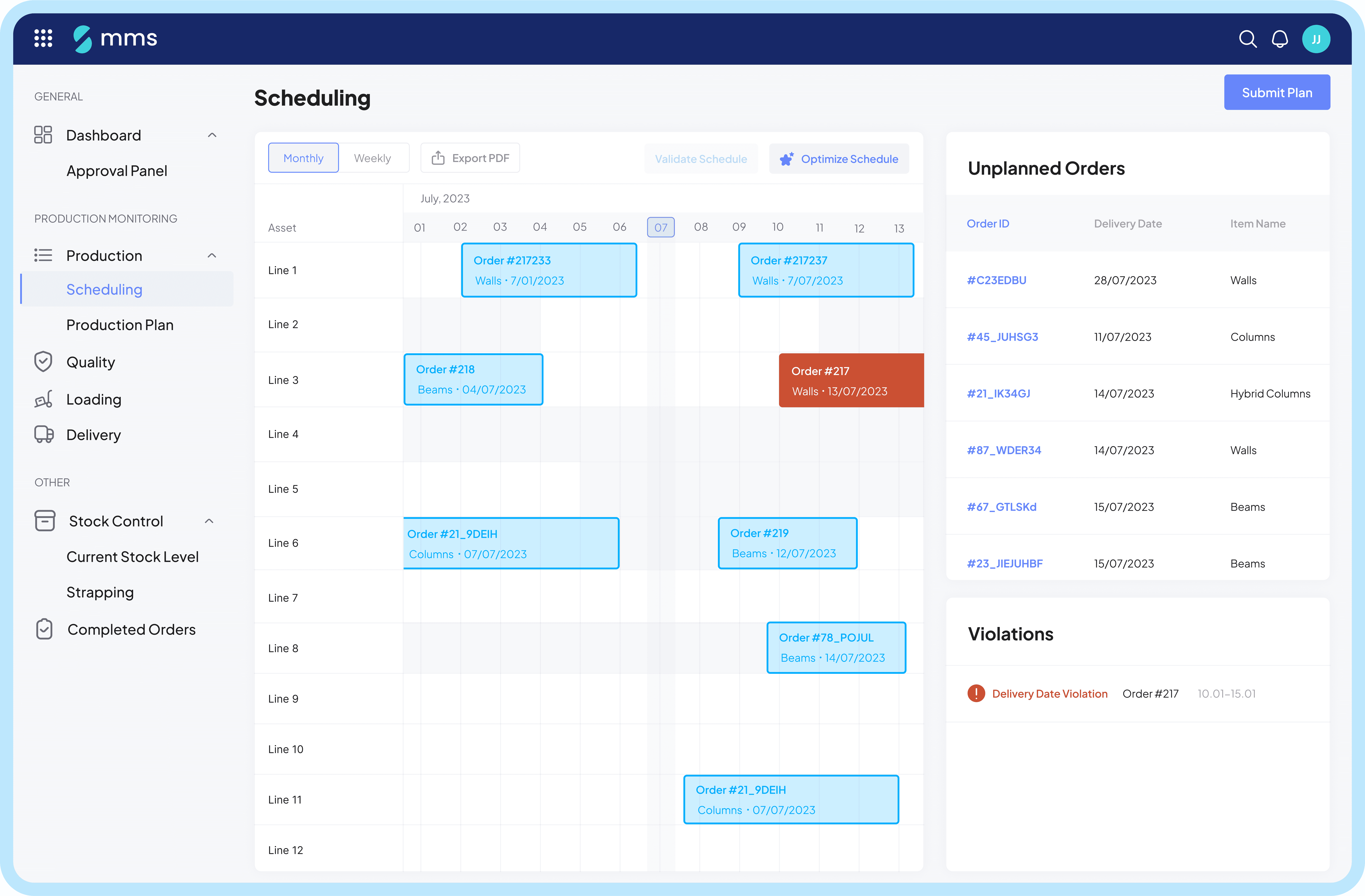

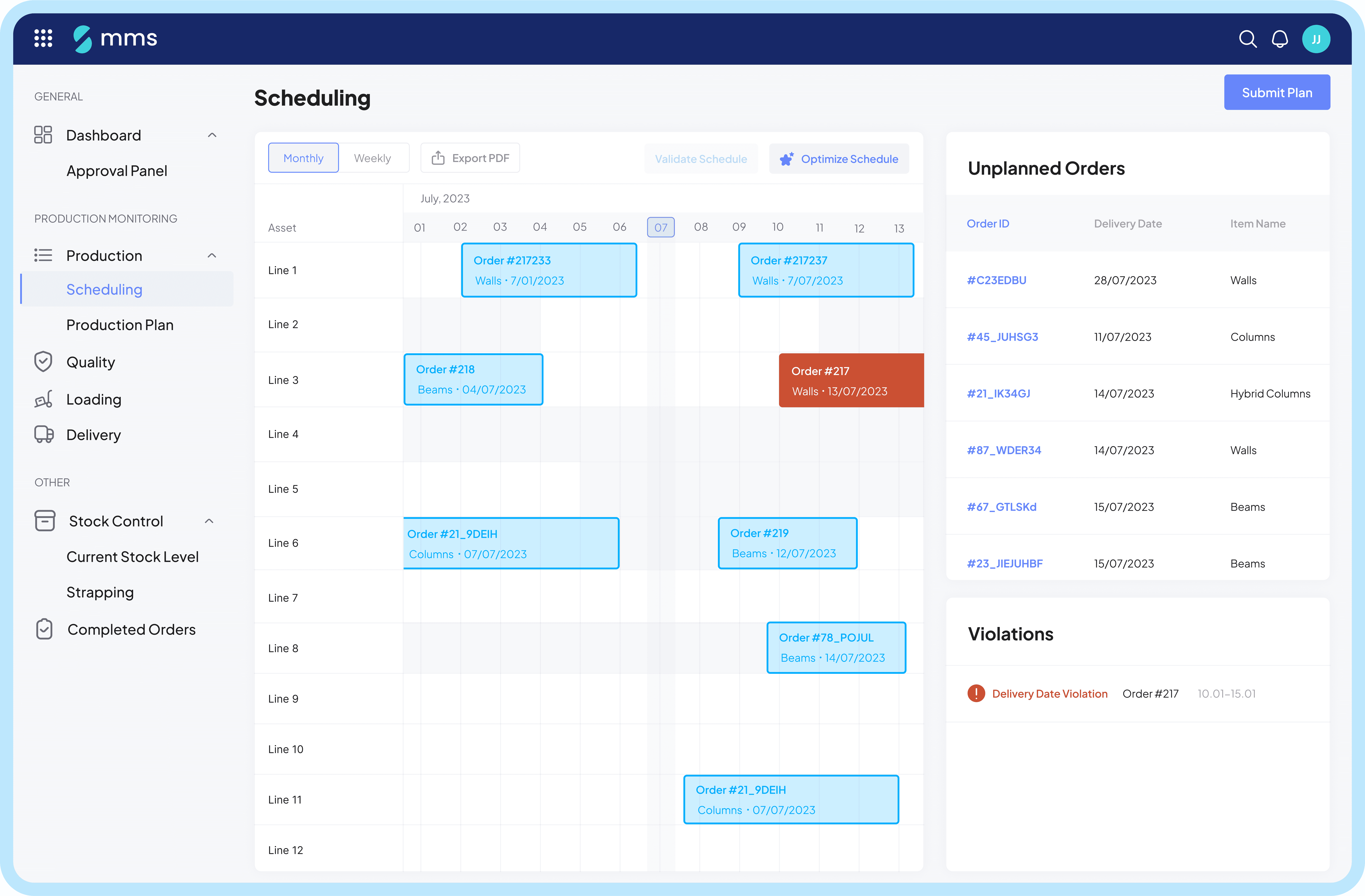

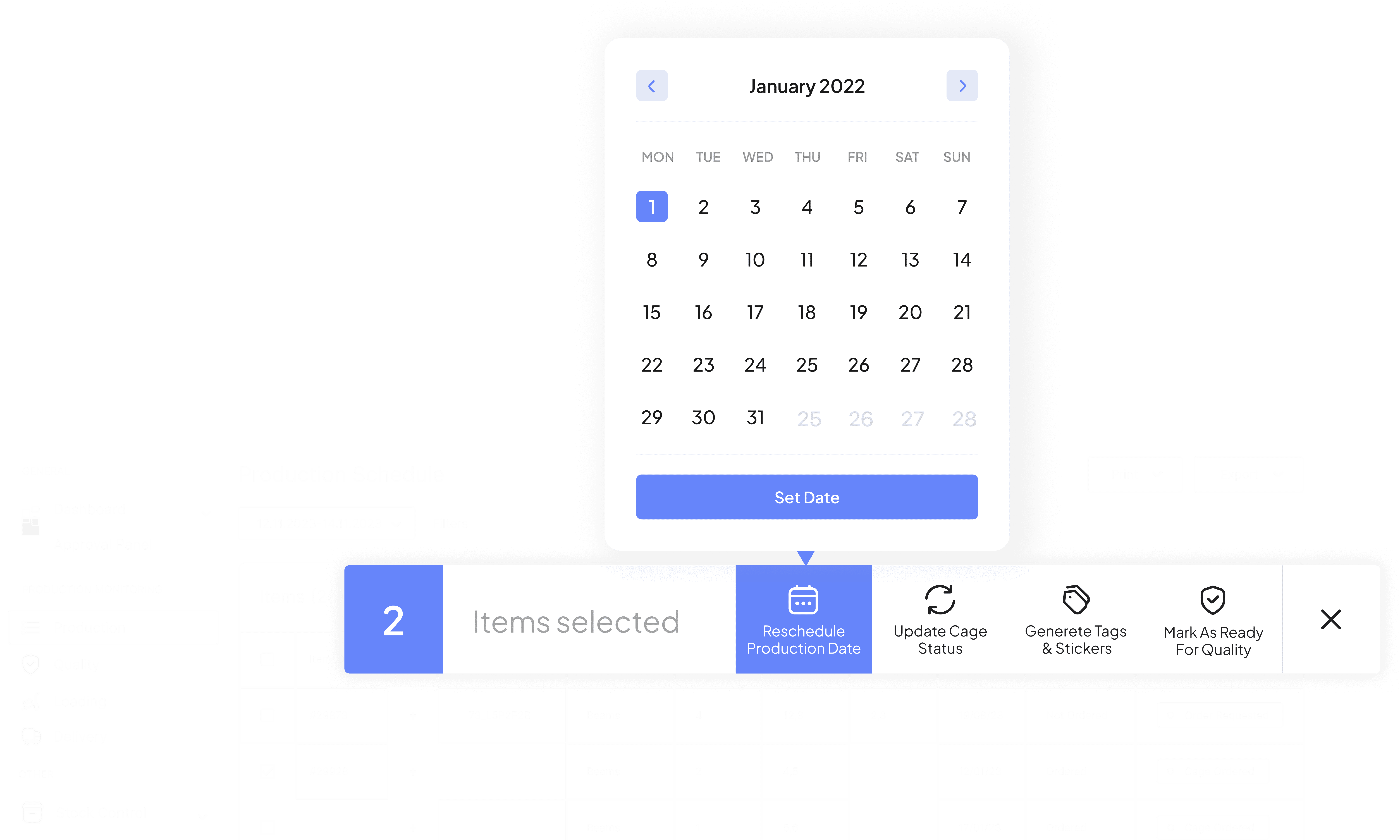

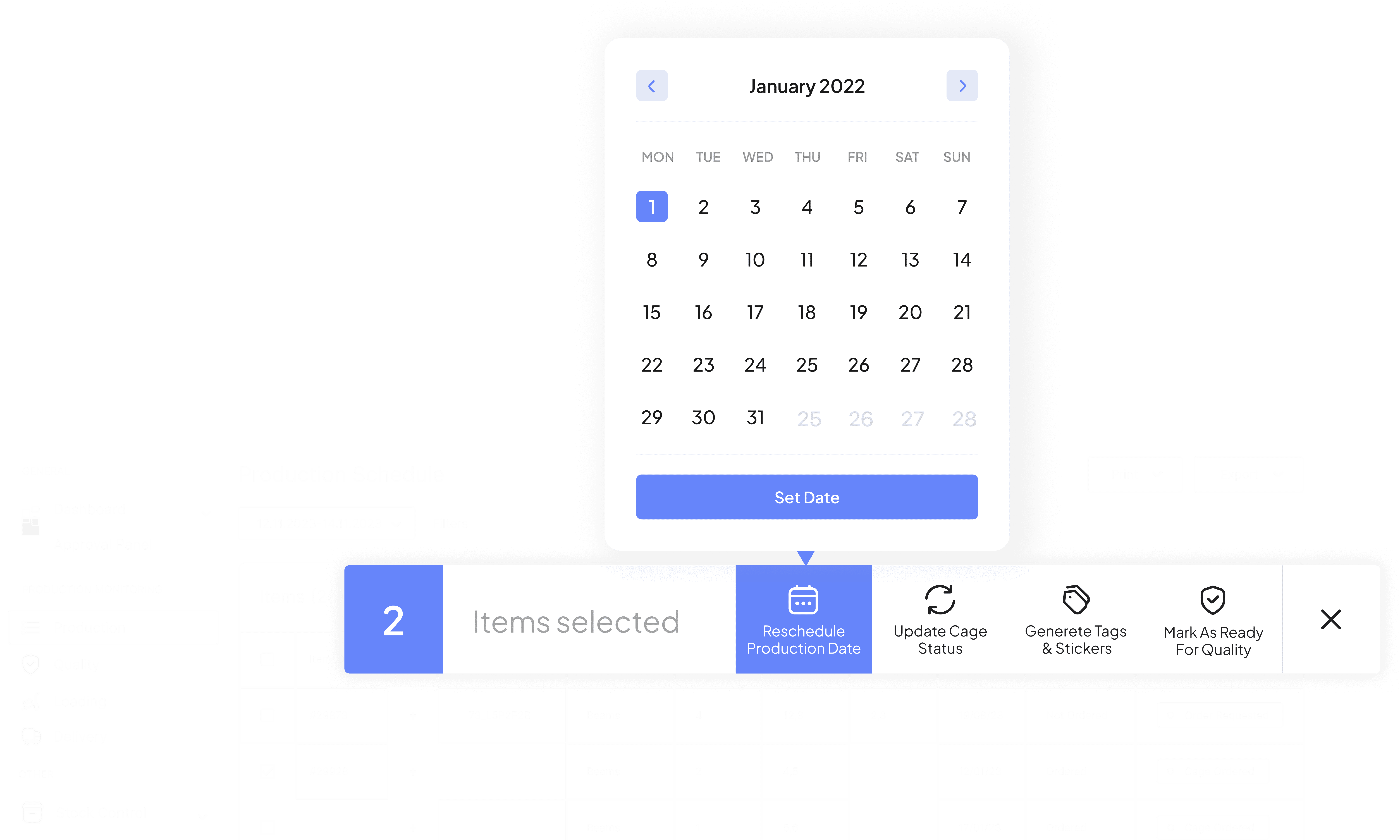

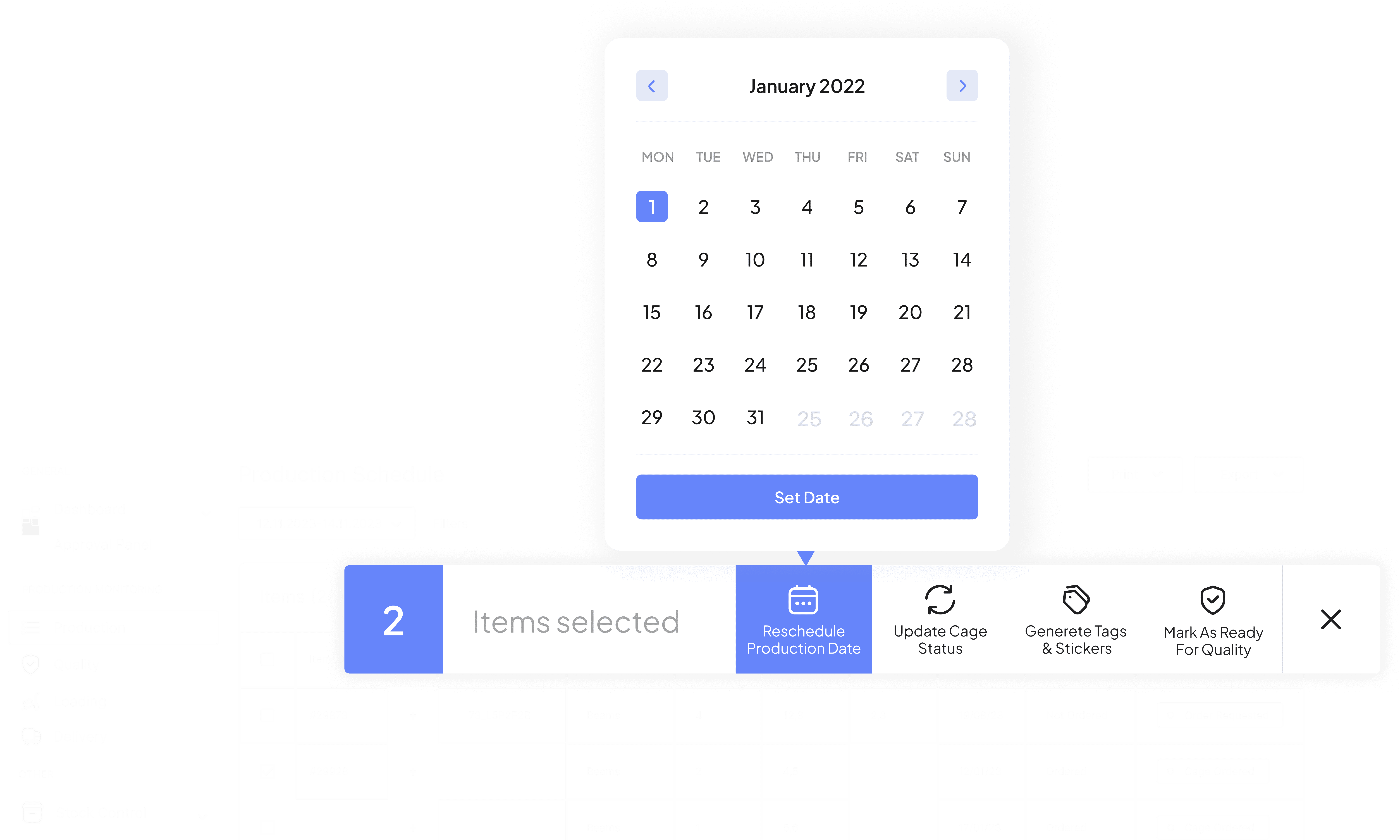

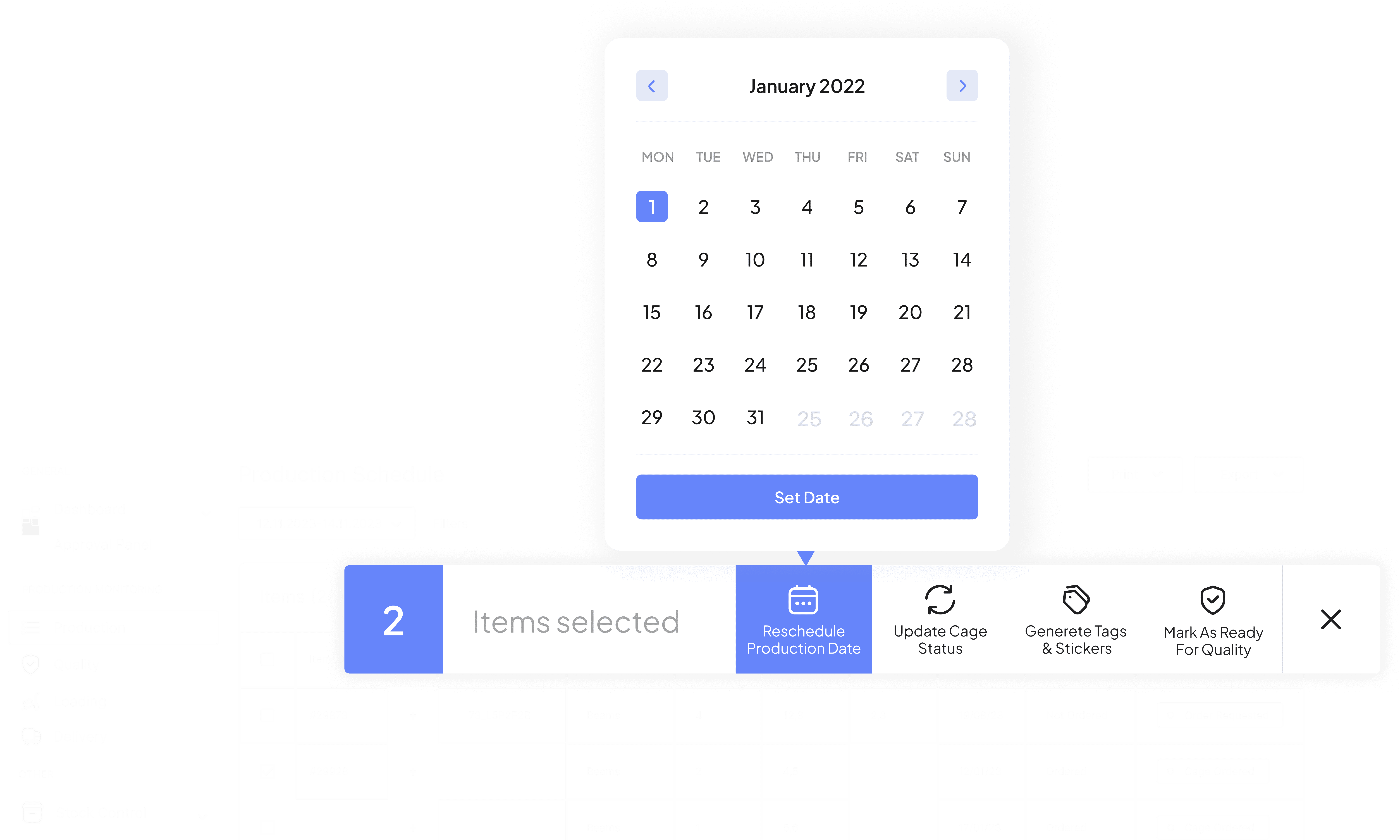

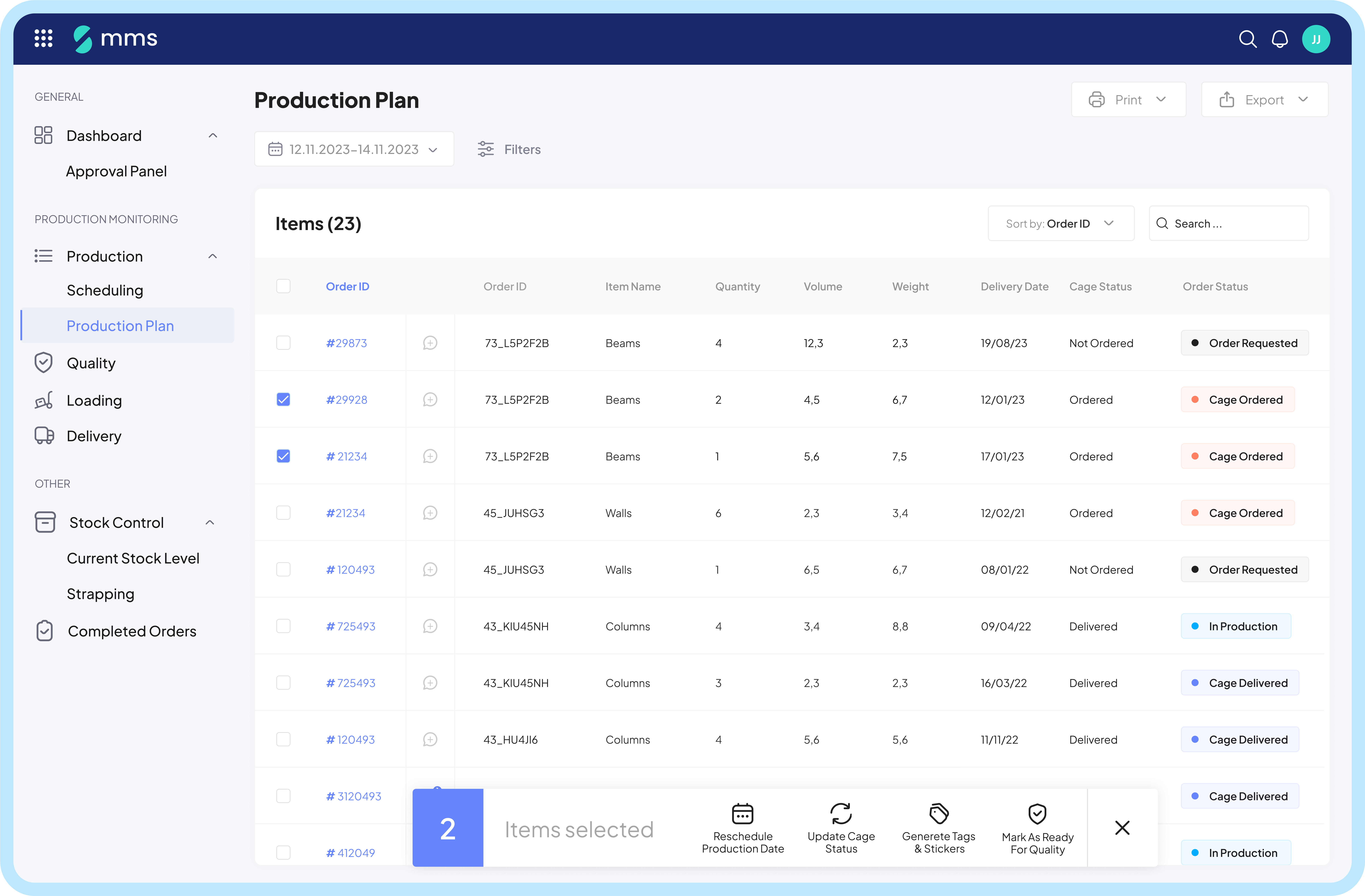

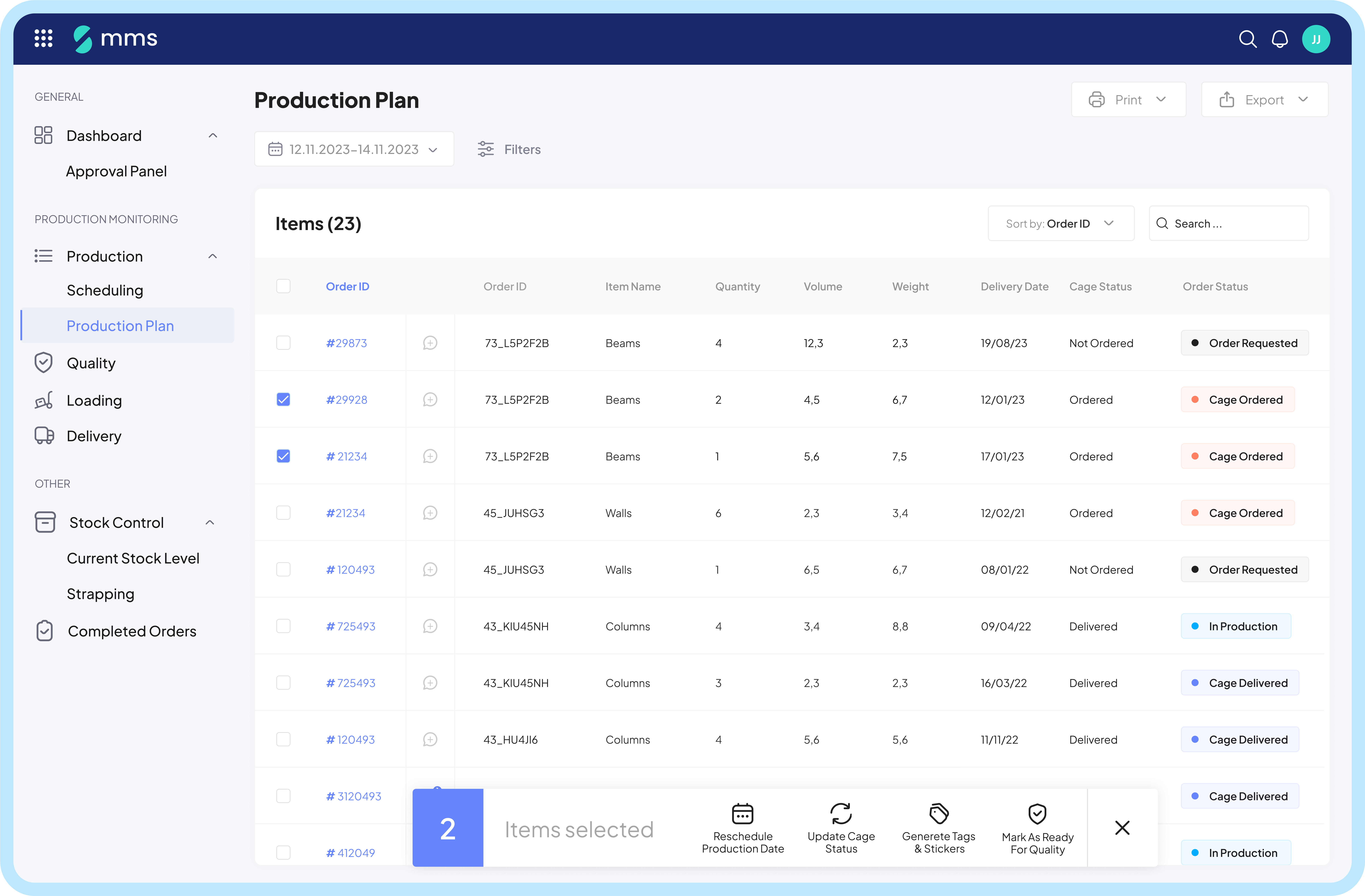

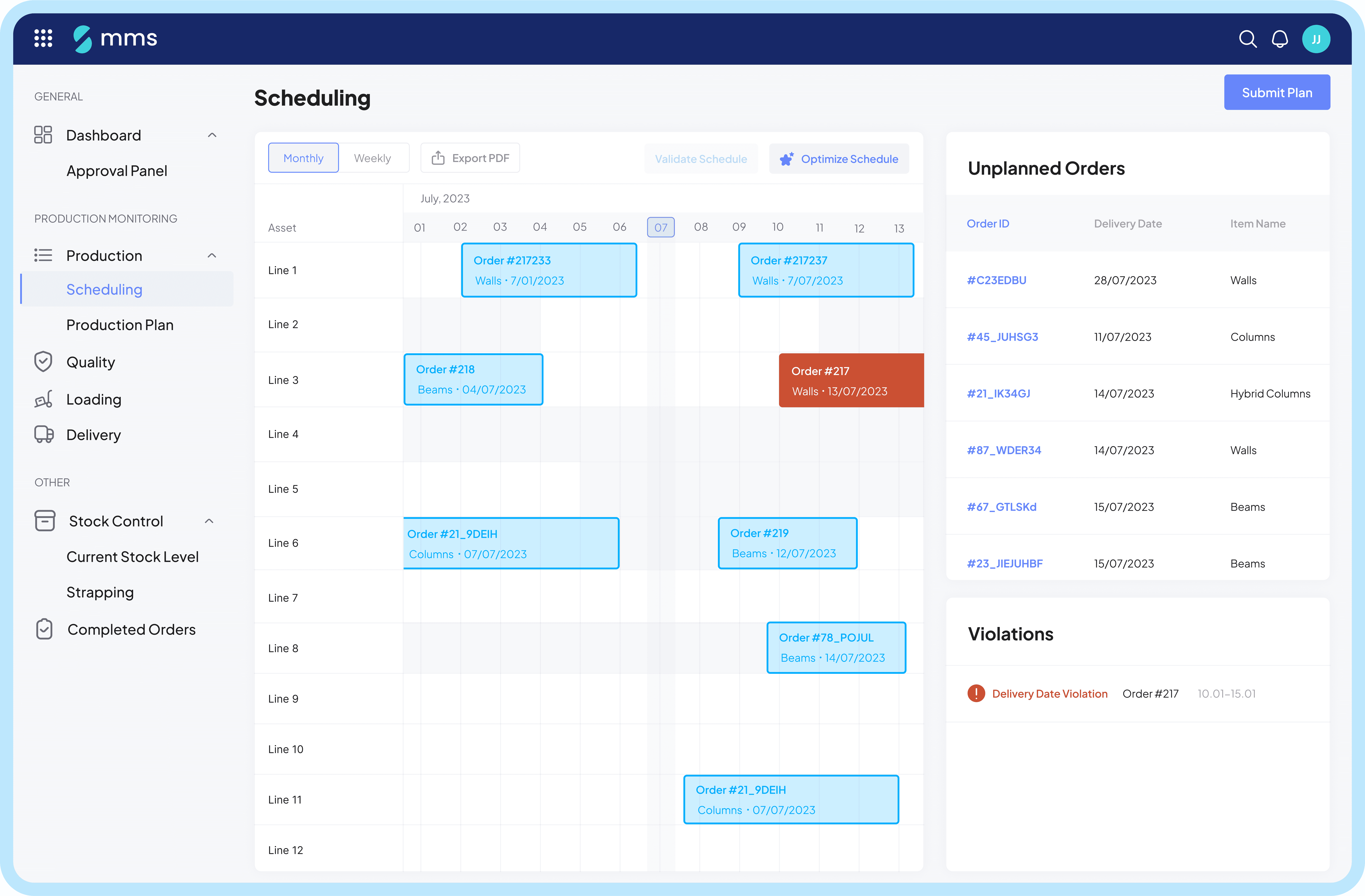

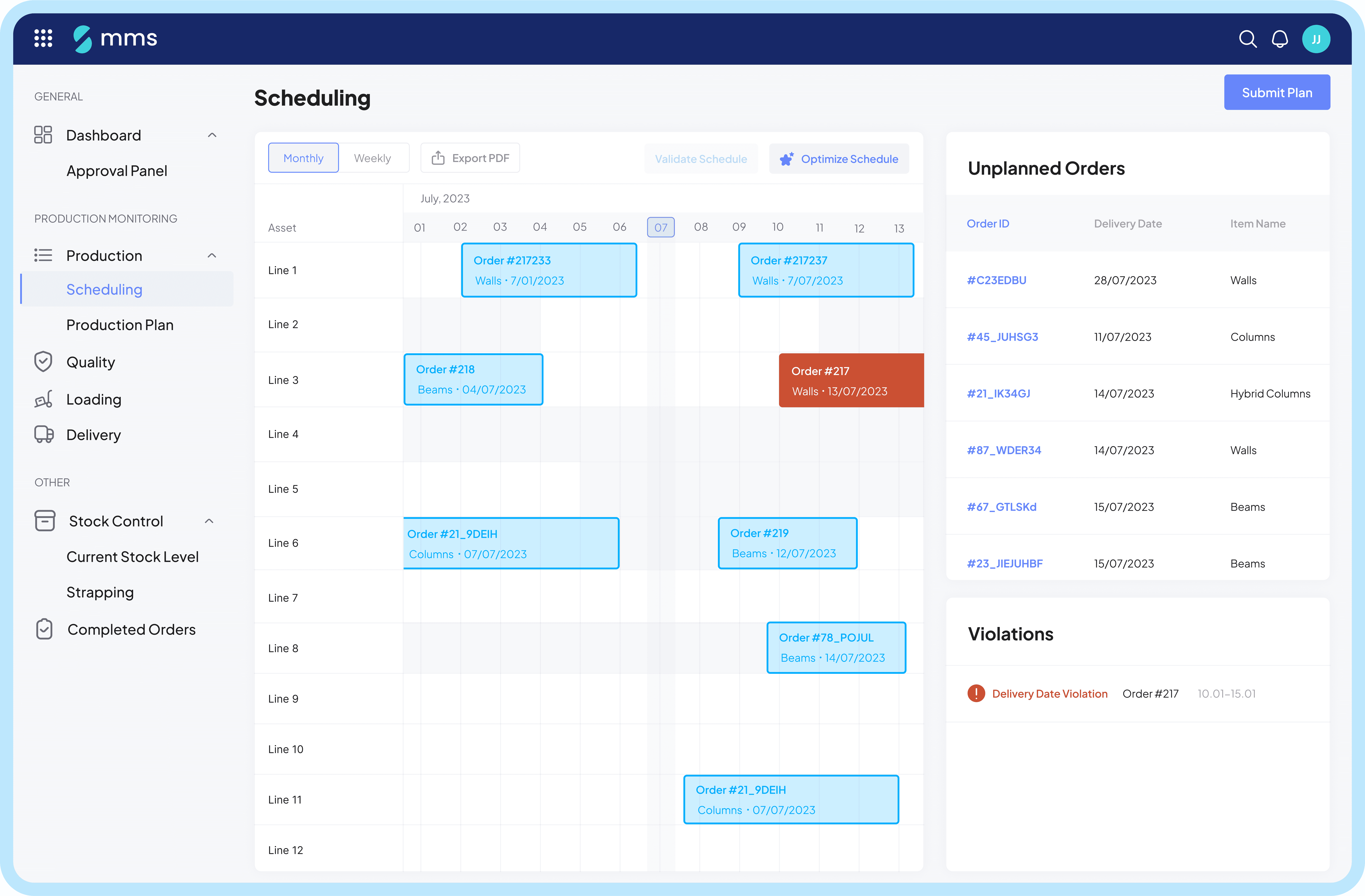

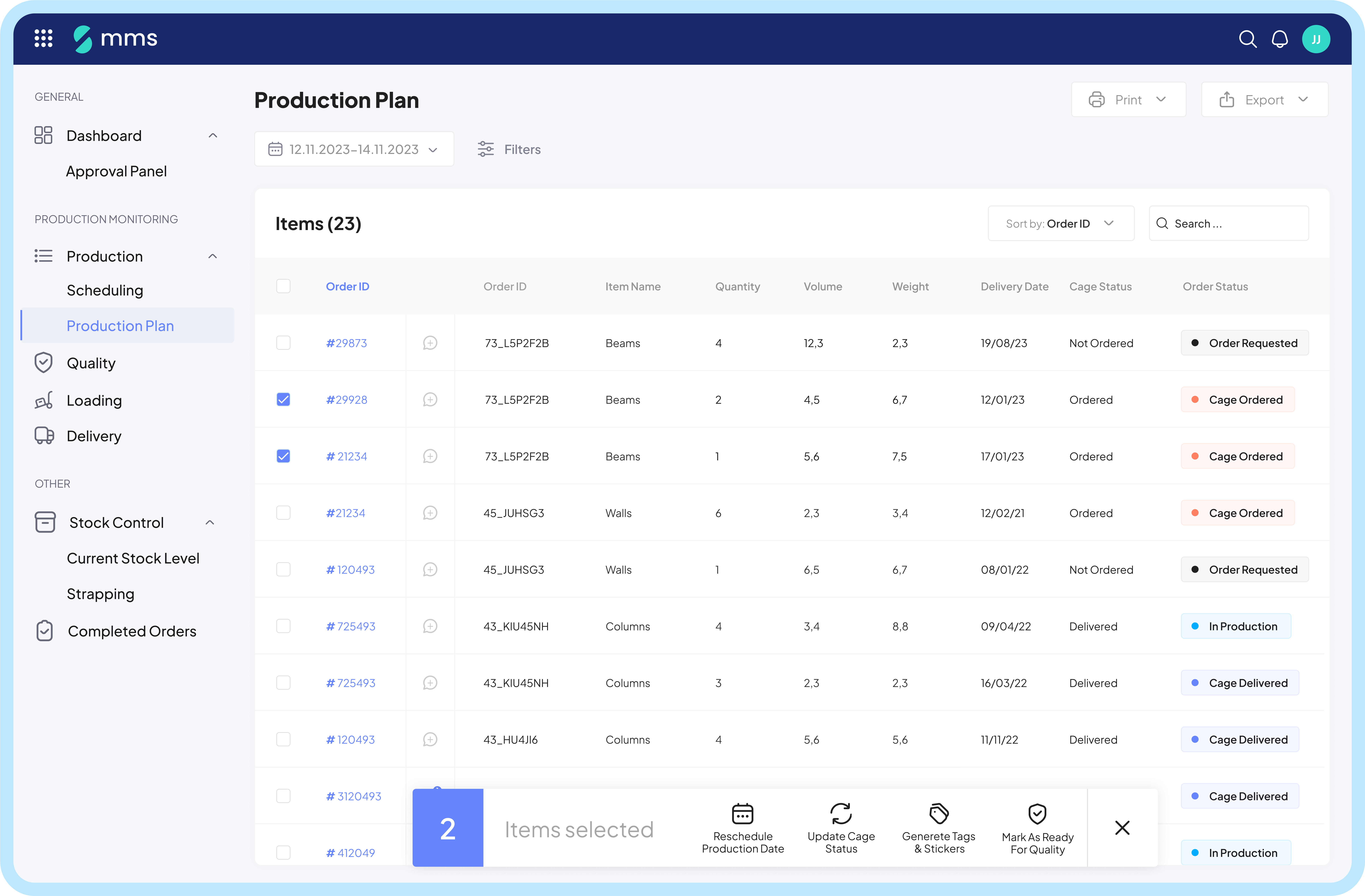

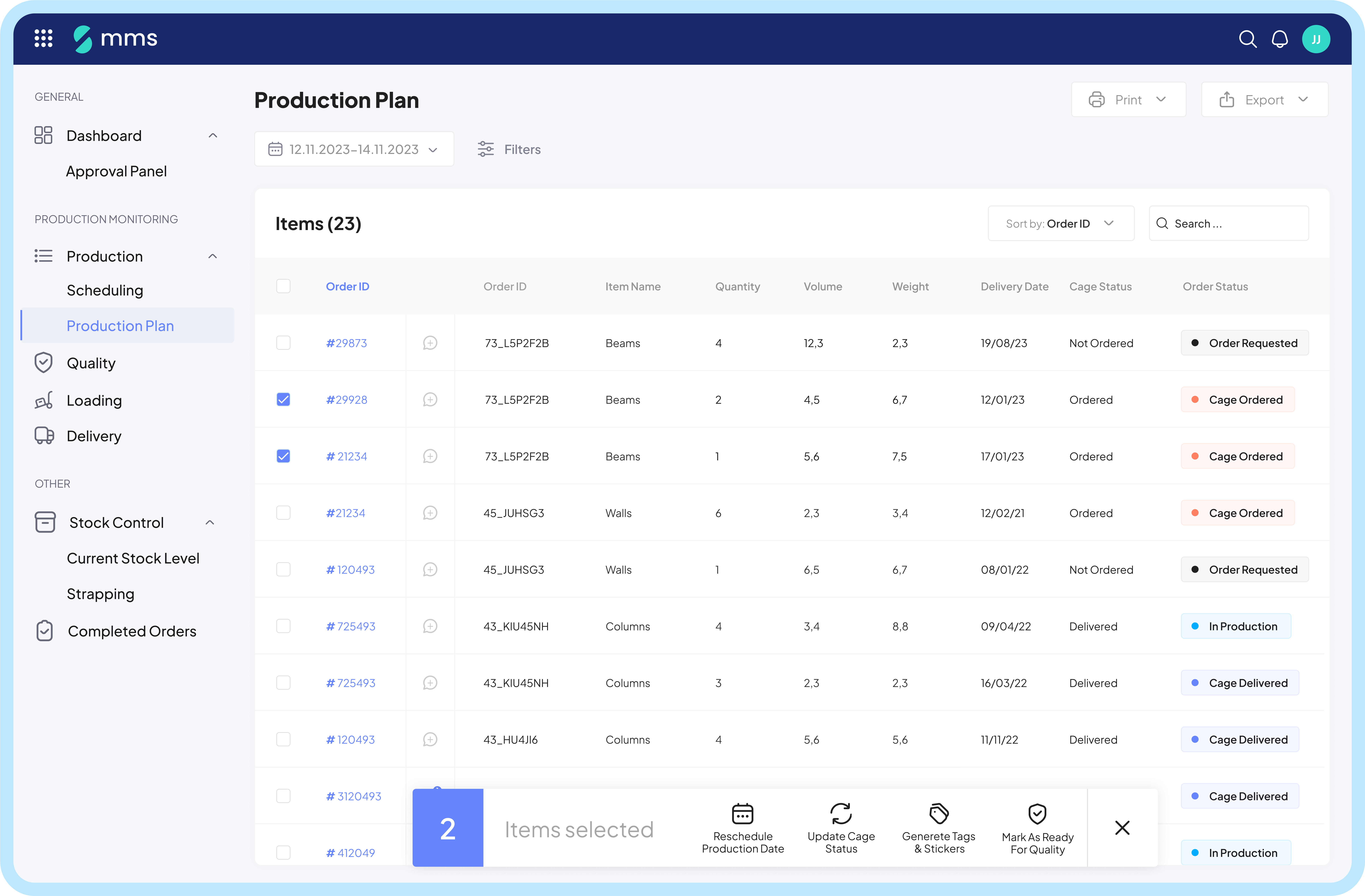

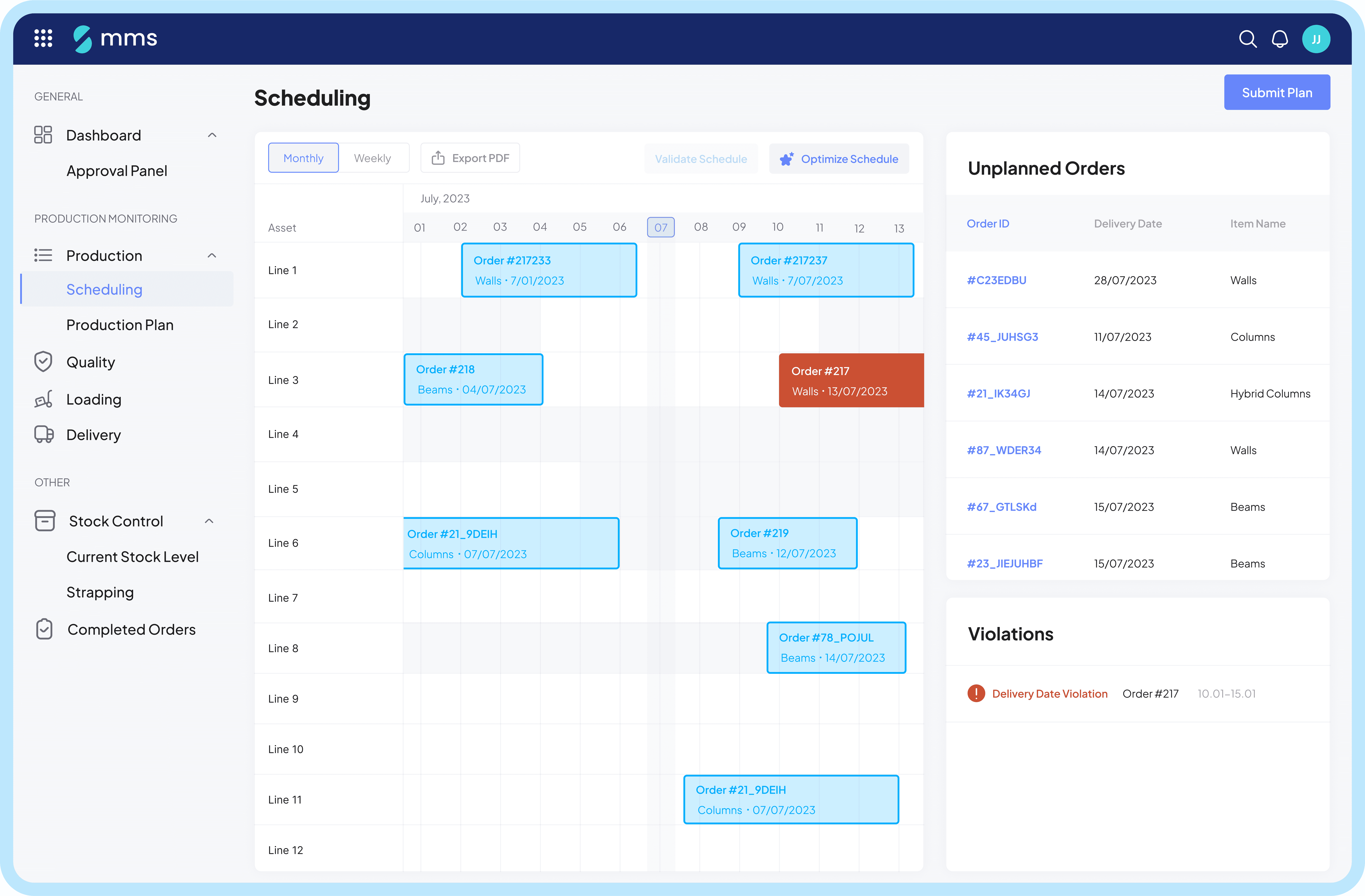

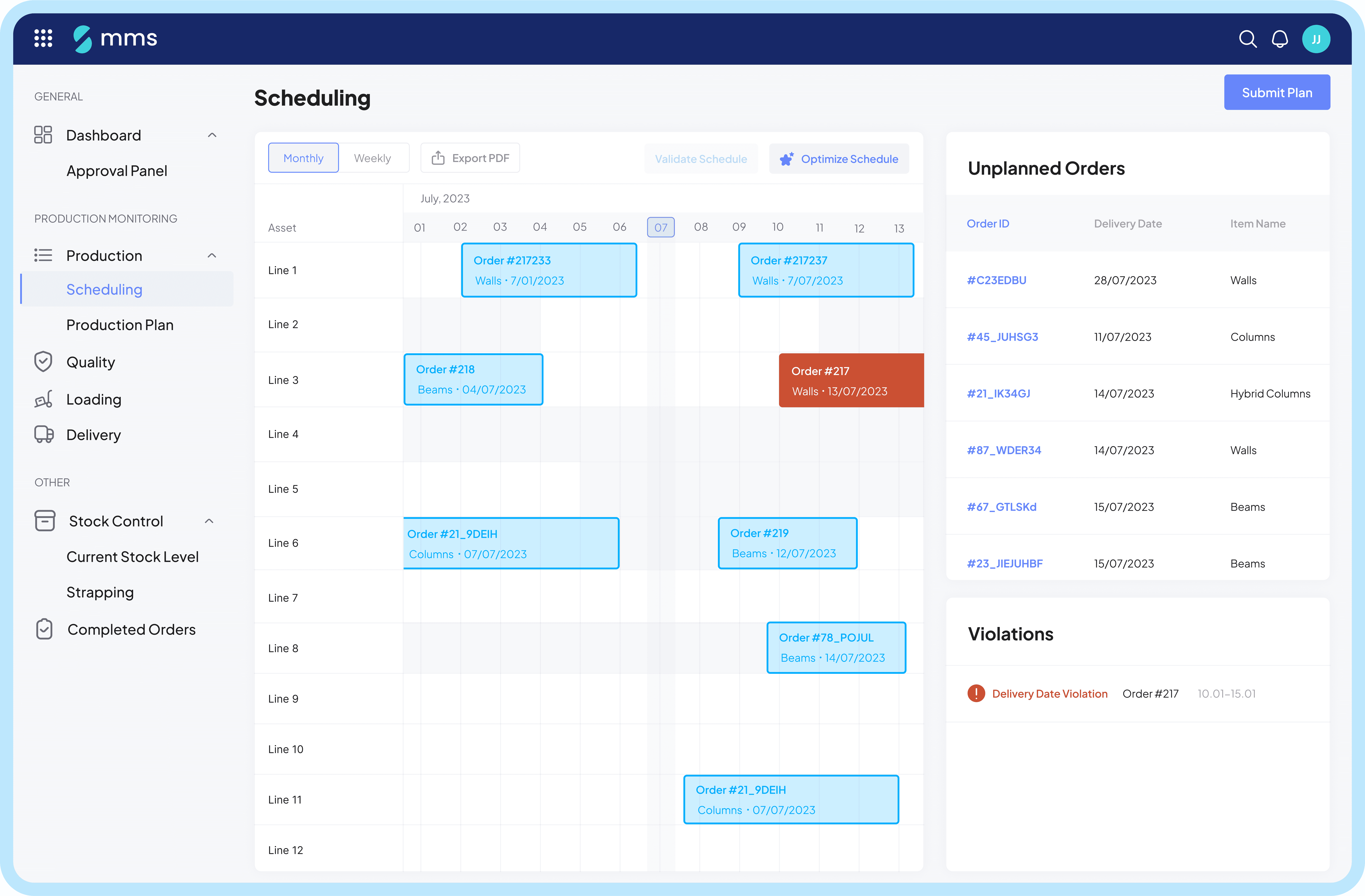

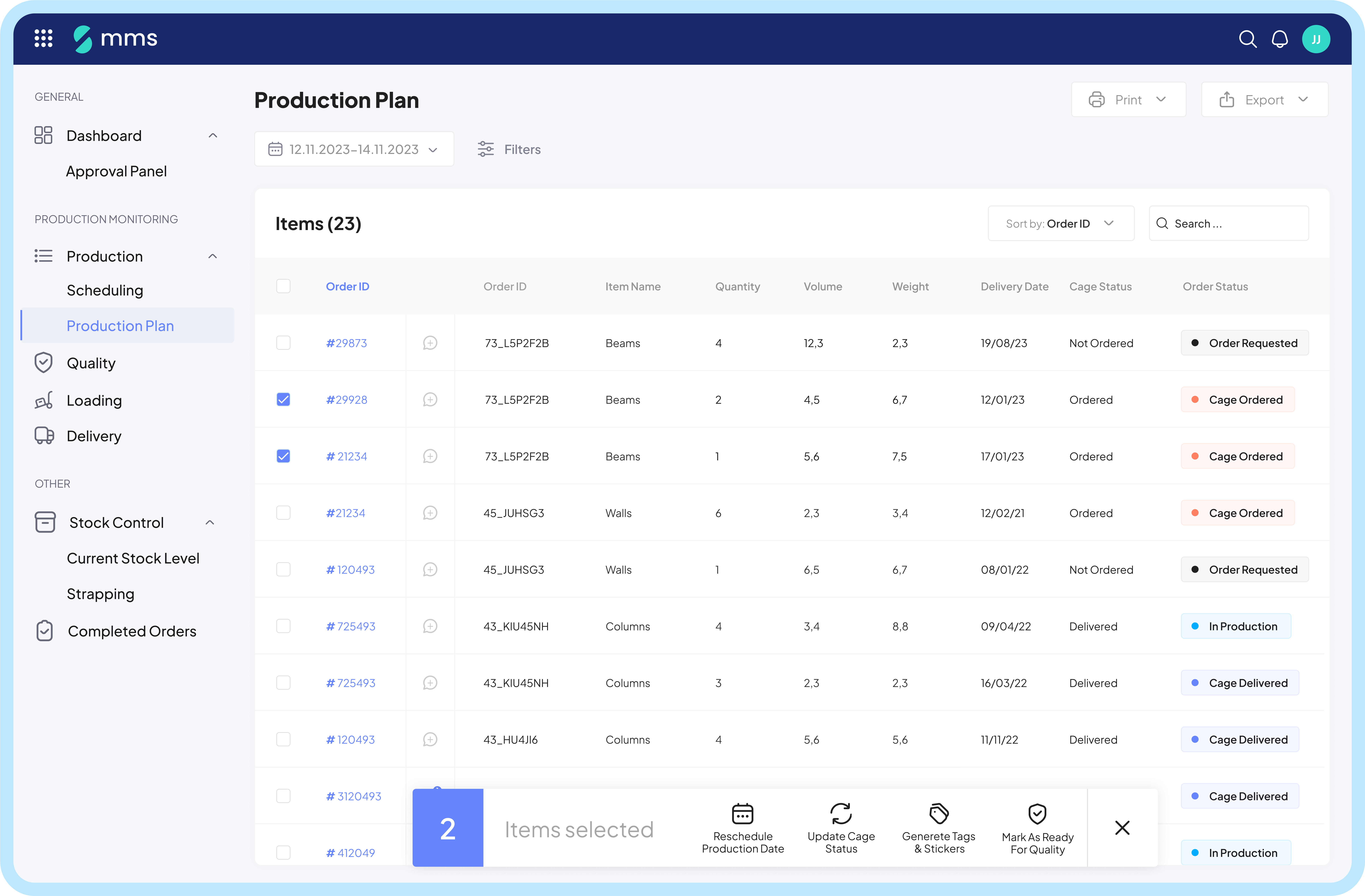

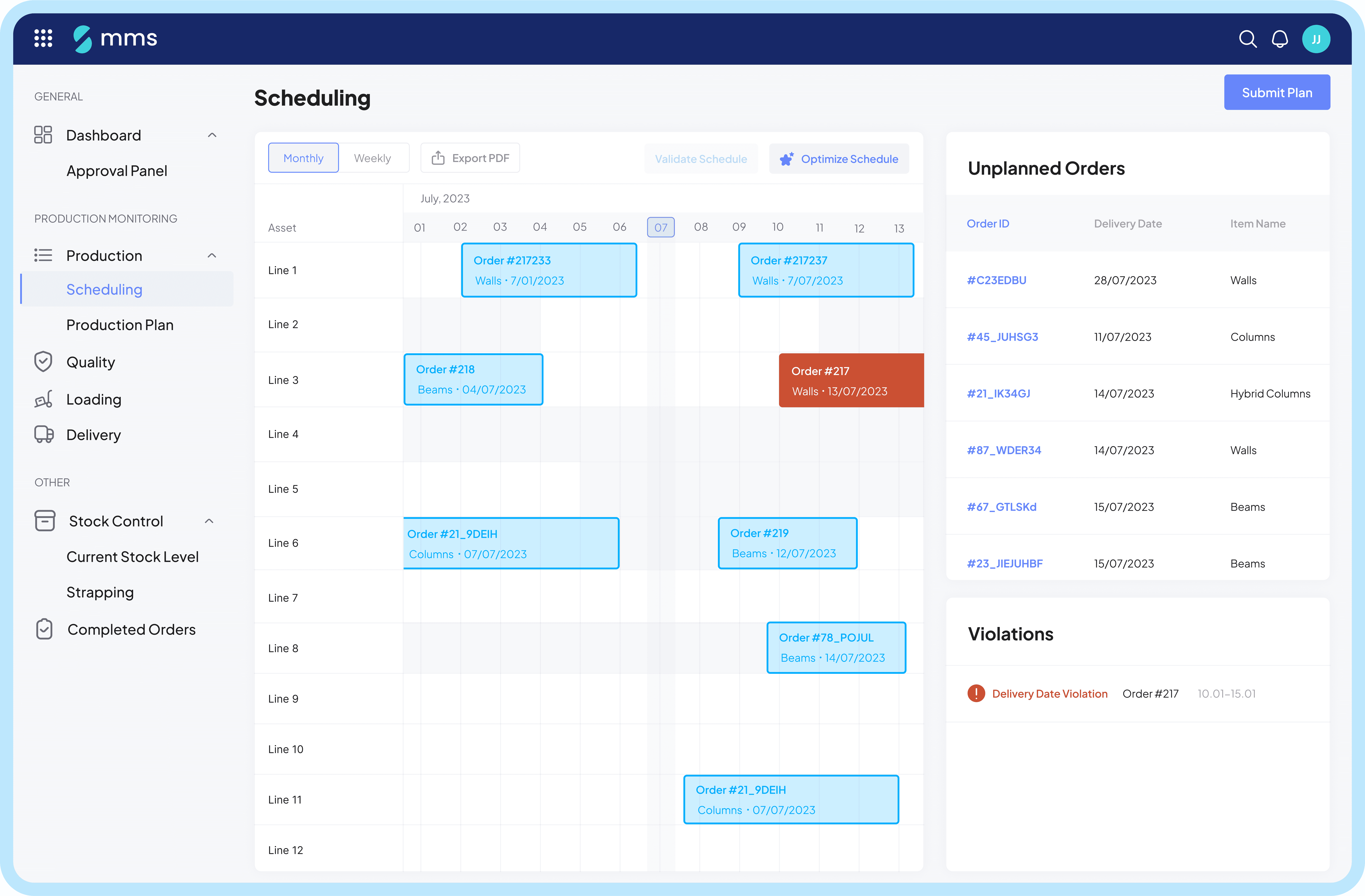

Production Planning

Easily plan your production by dragging and dropping unplanned orders on a calendar, adjusting timelines for optimal use of available capacity. Gain a clear, visual overview of all orders. Plus, conveniently select multiple orders to generate tags and adjust production dates as needed for added flexibility and efficiency.

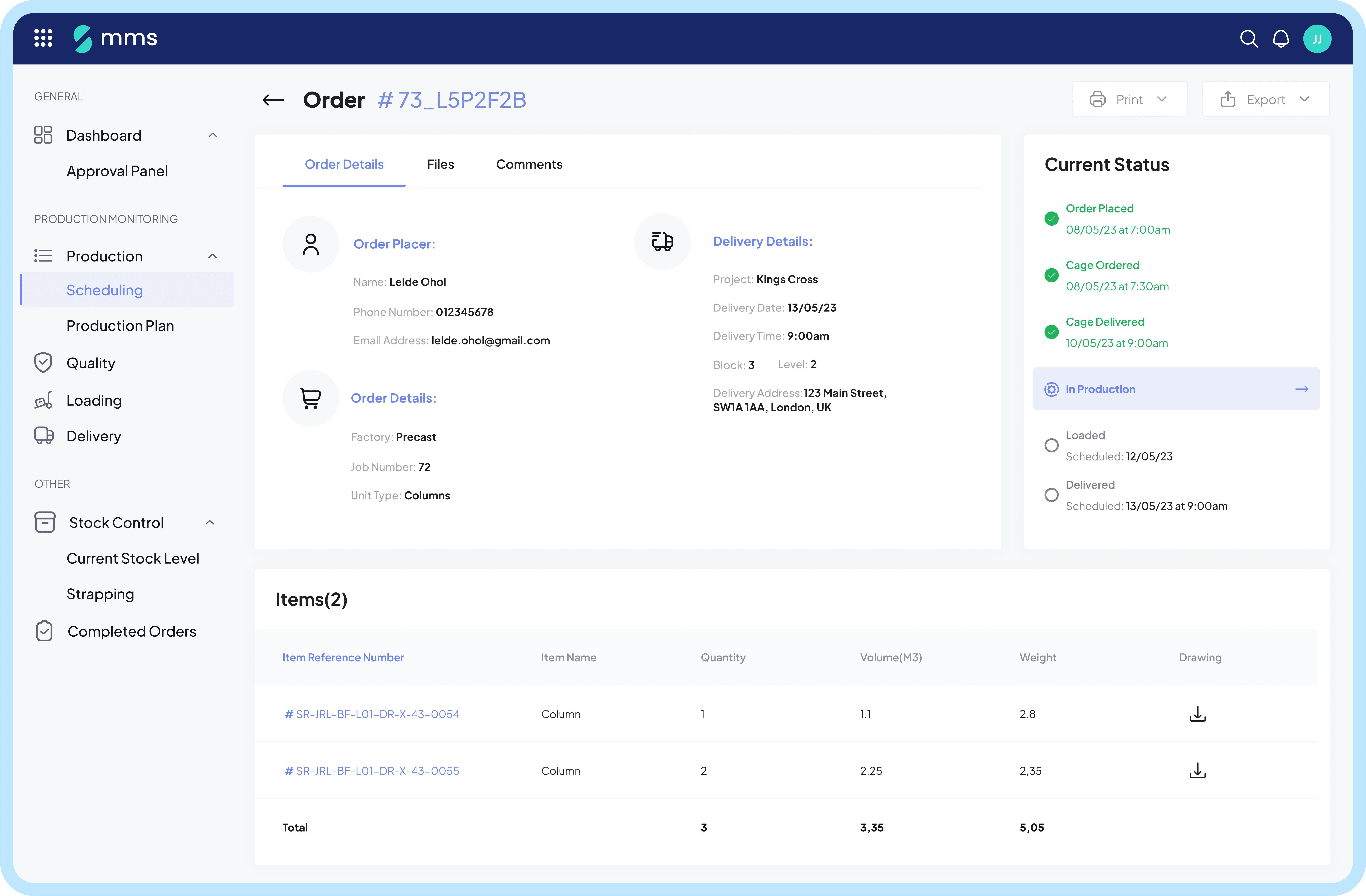

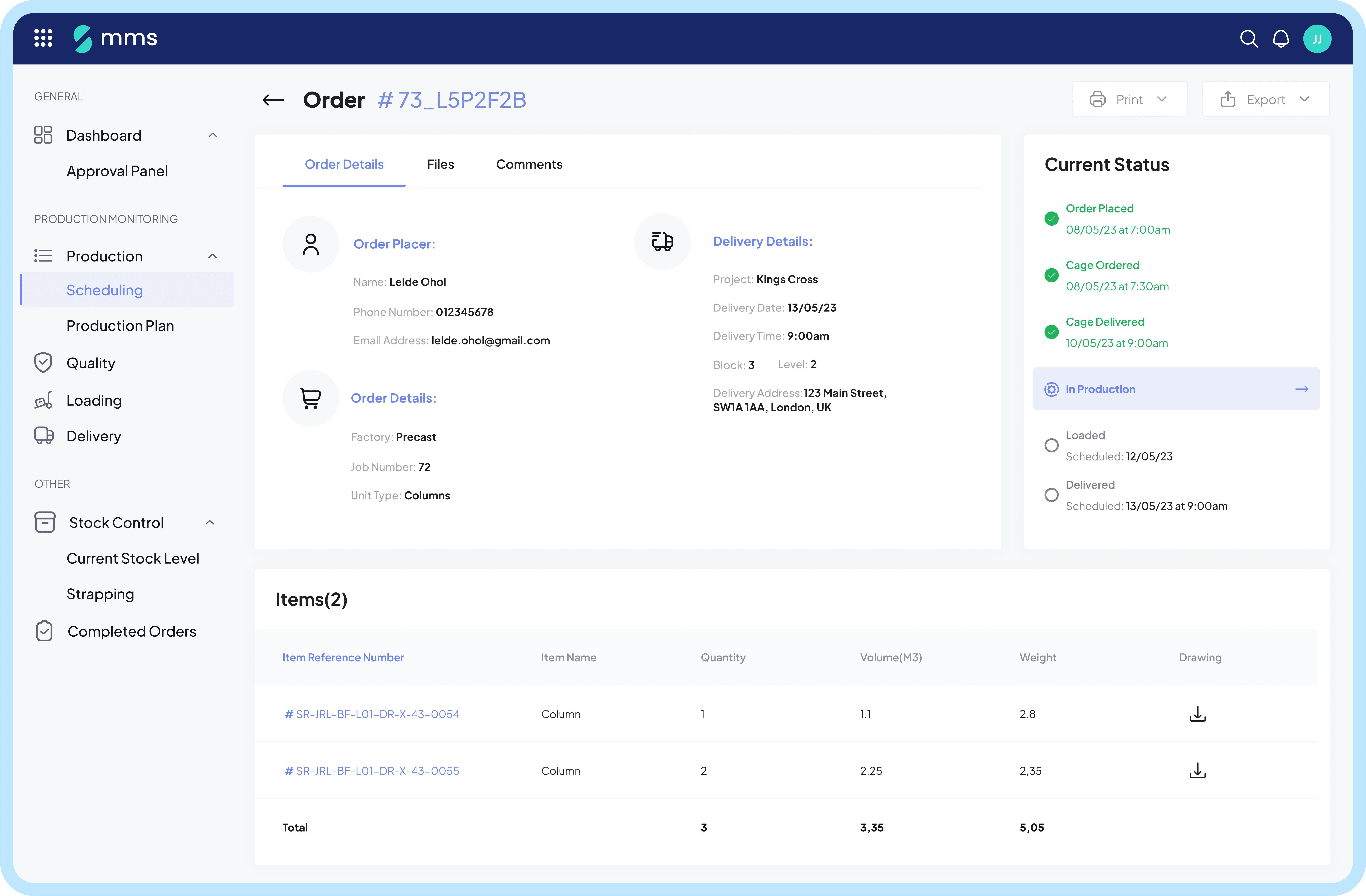

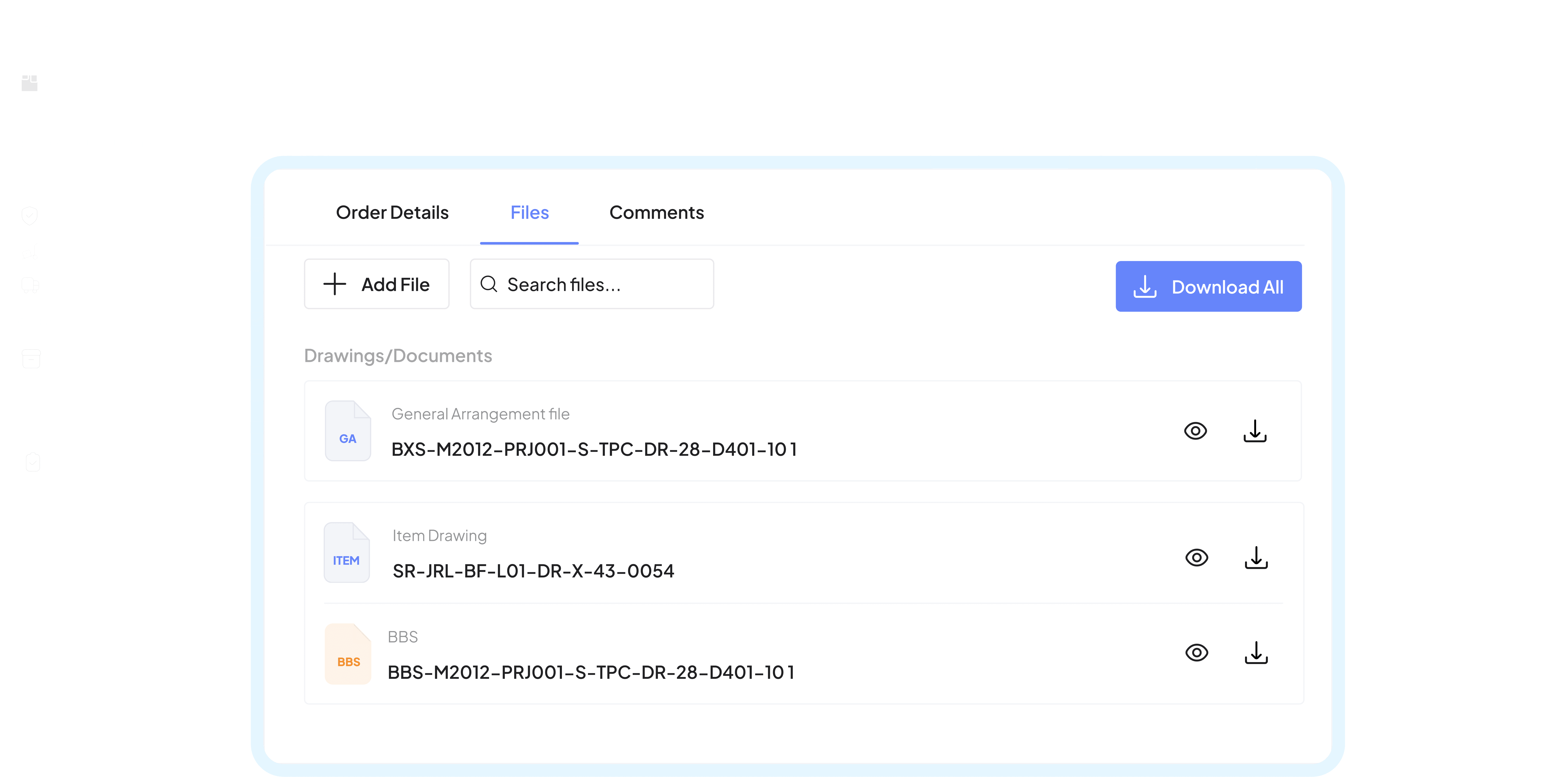

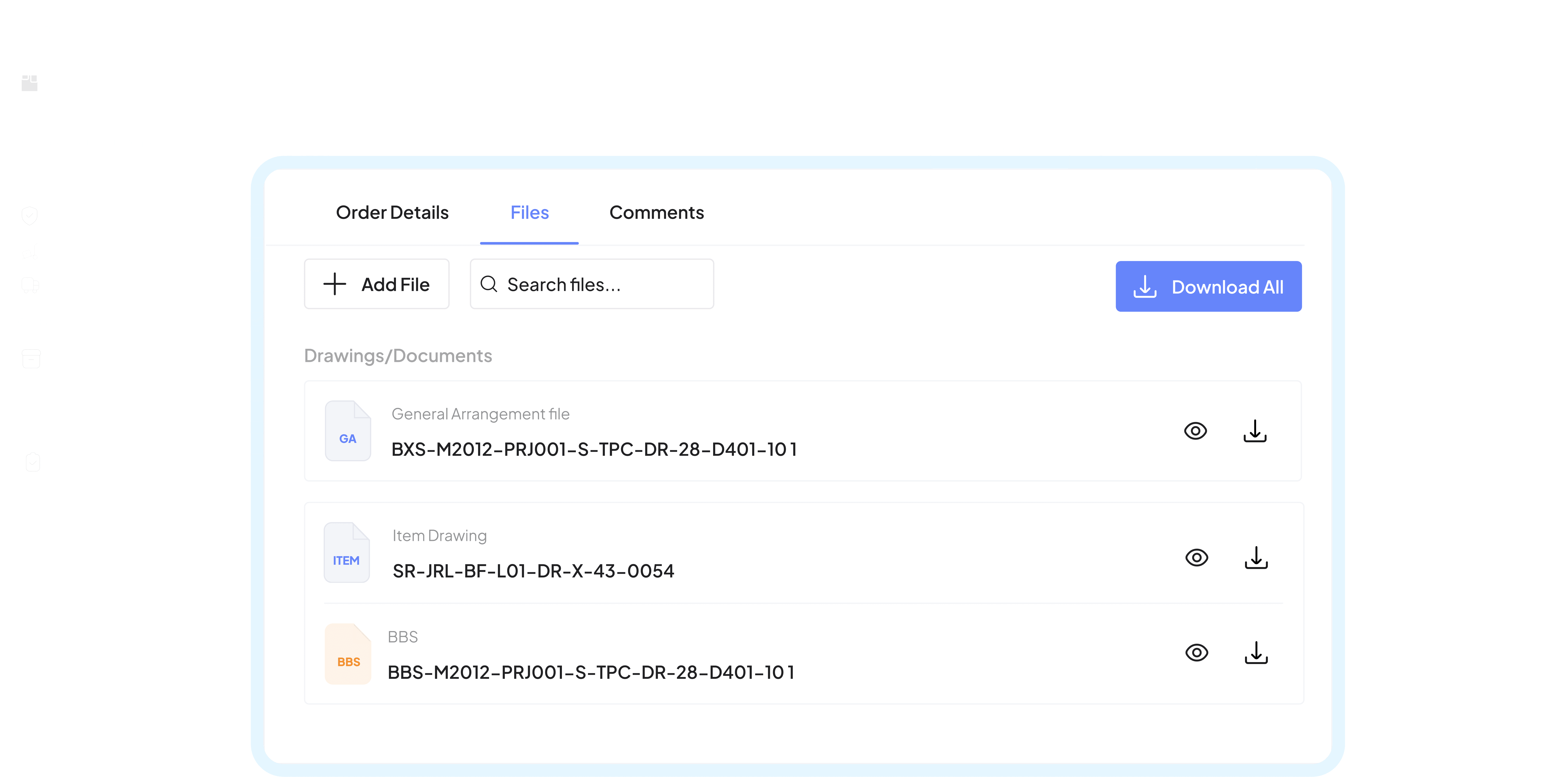

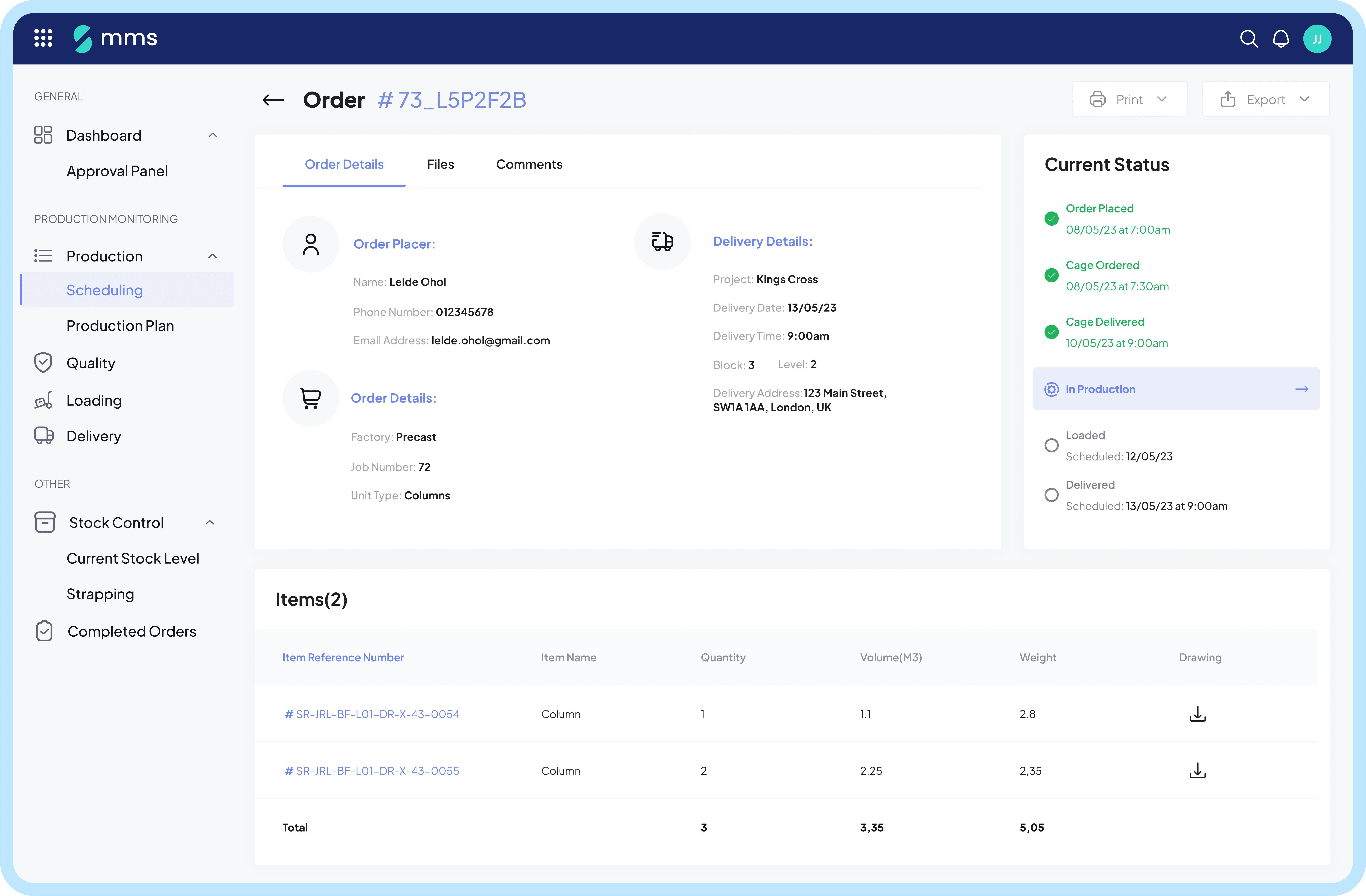

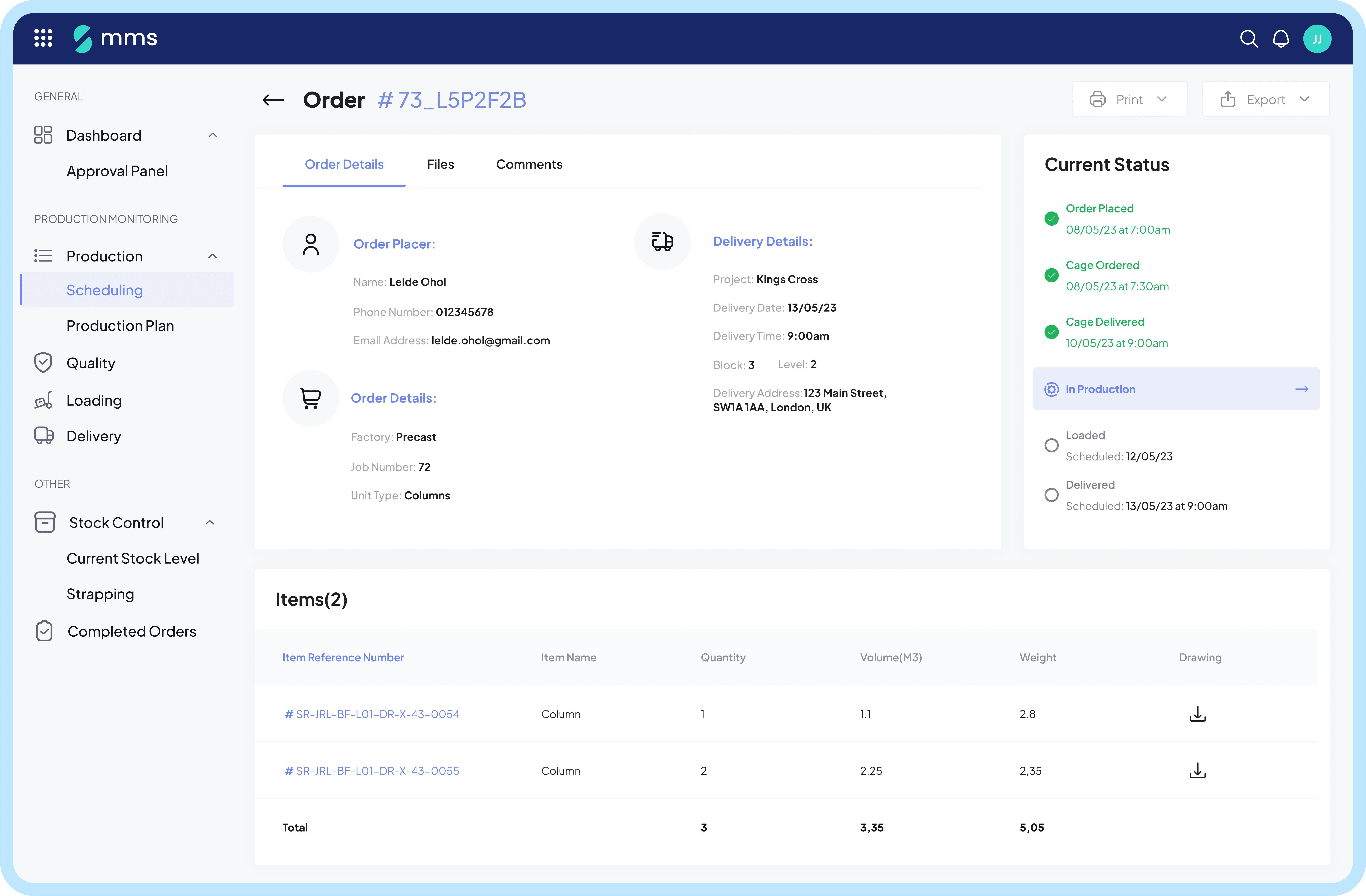

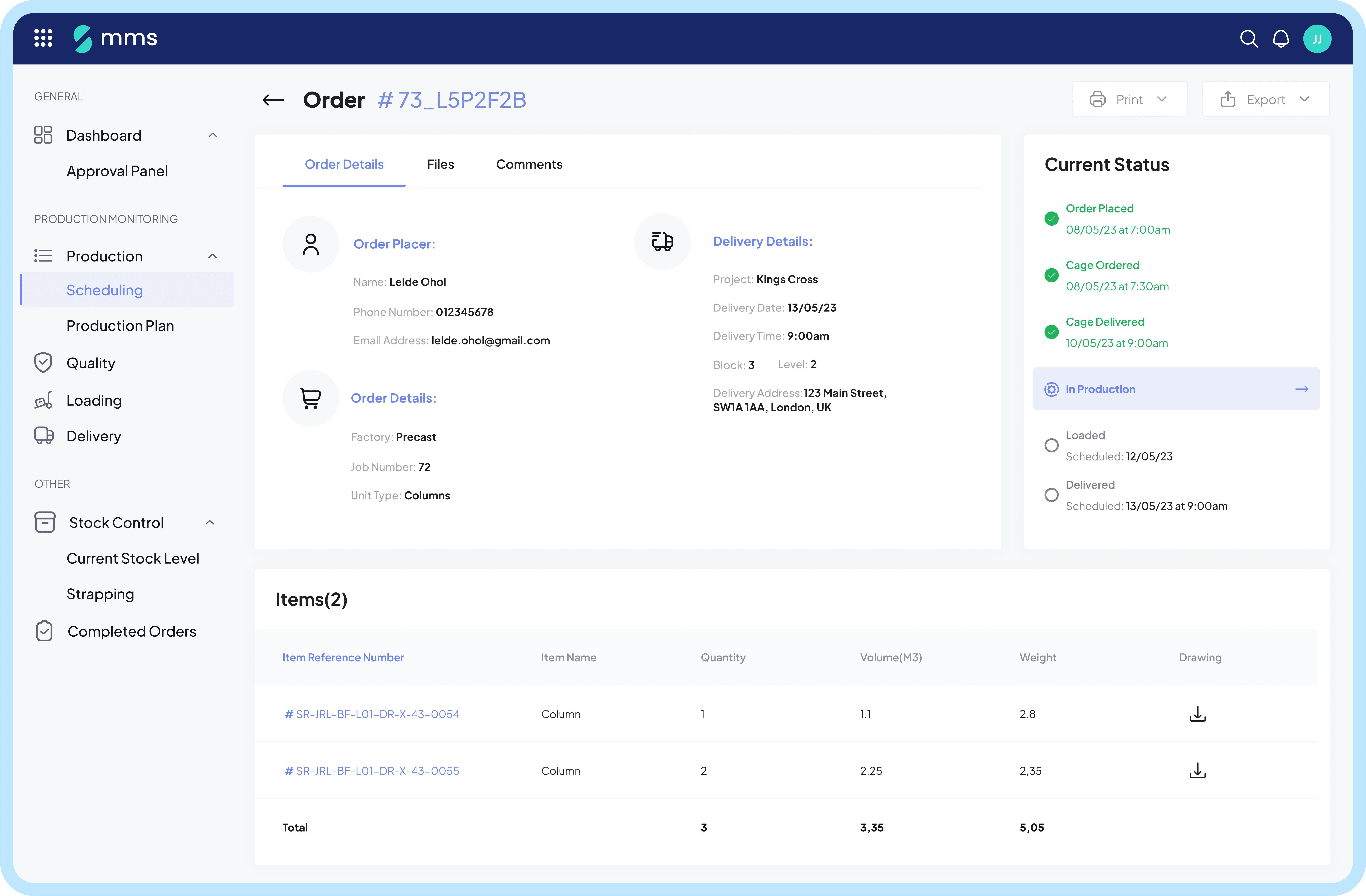

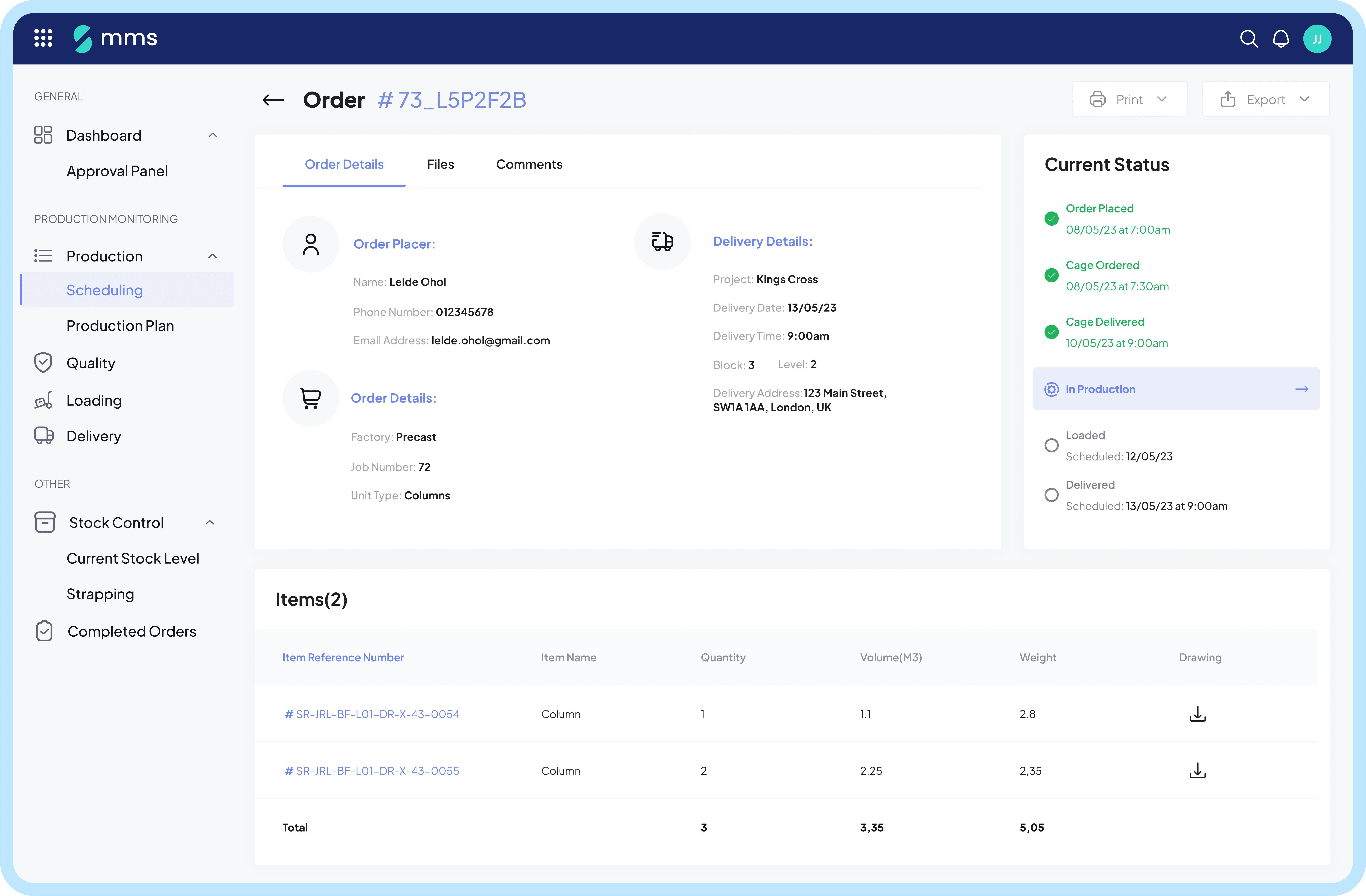

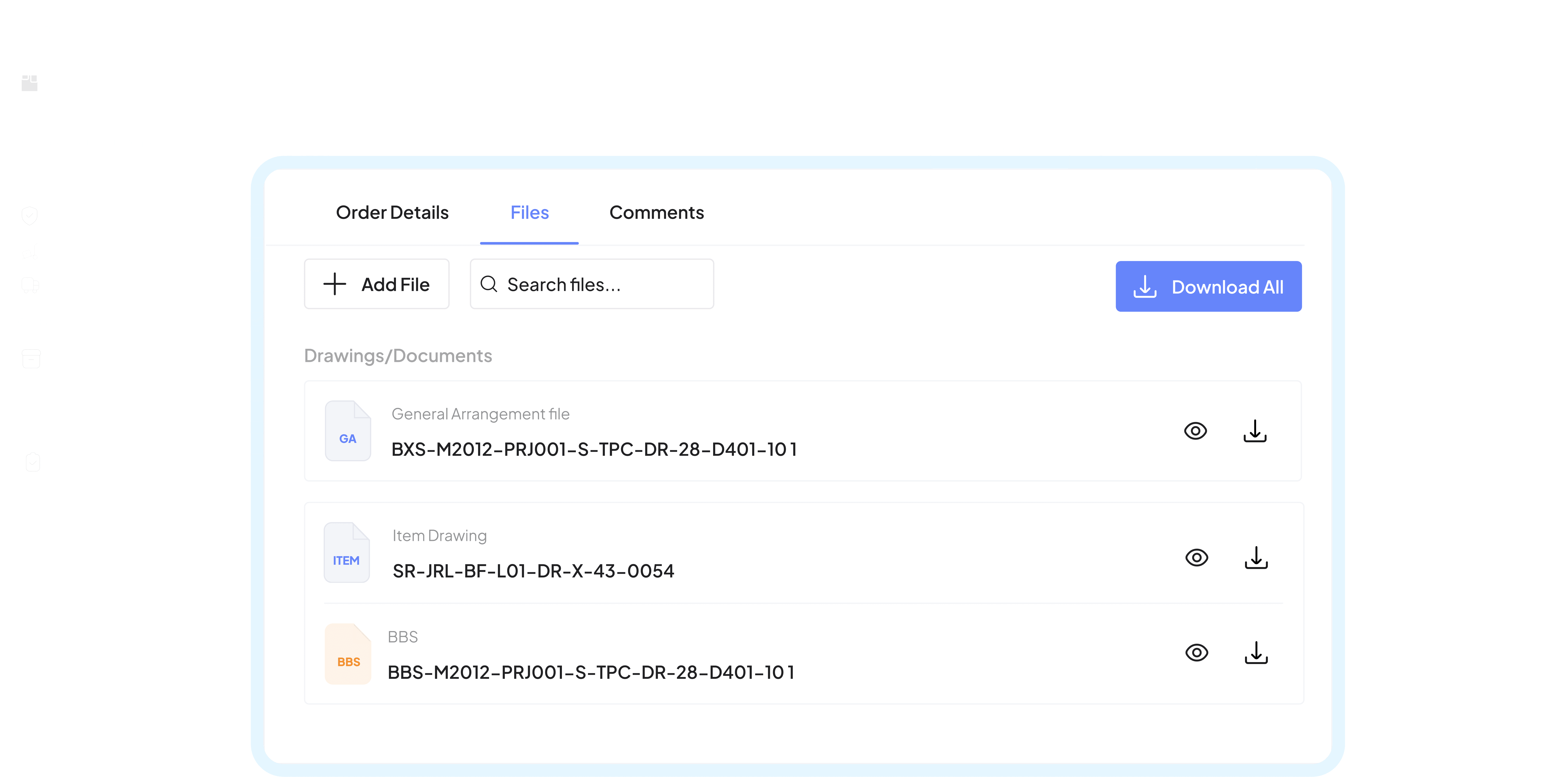

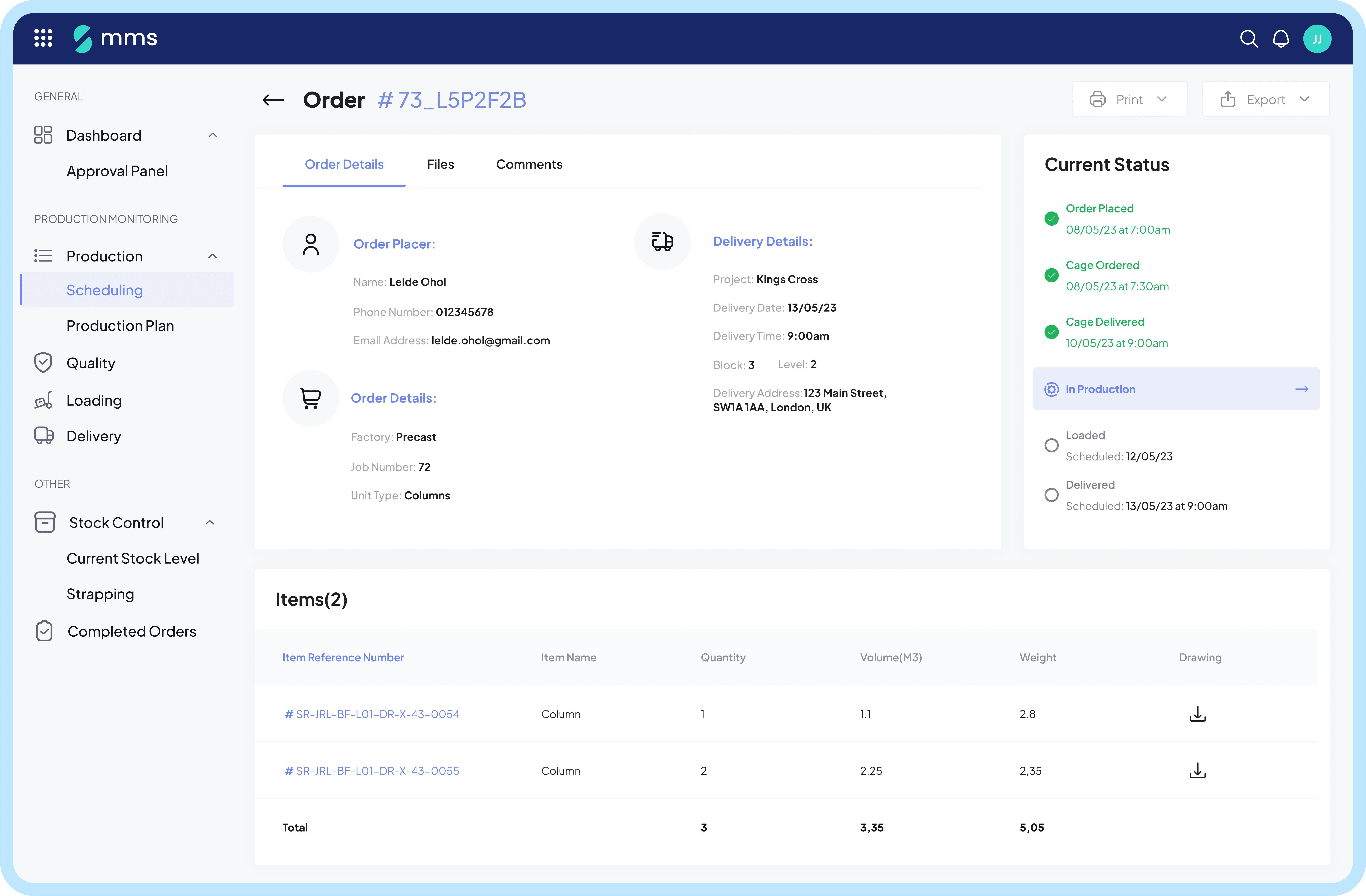

Order Details

detailed history and current status with precise dates and times. Easily track the evolution of the order, add comments, and download all required files.

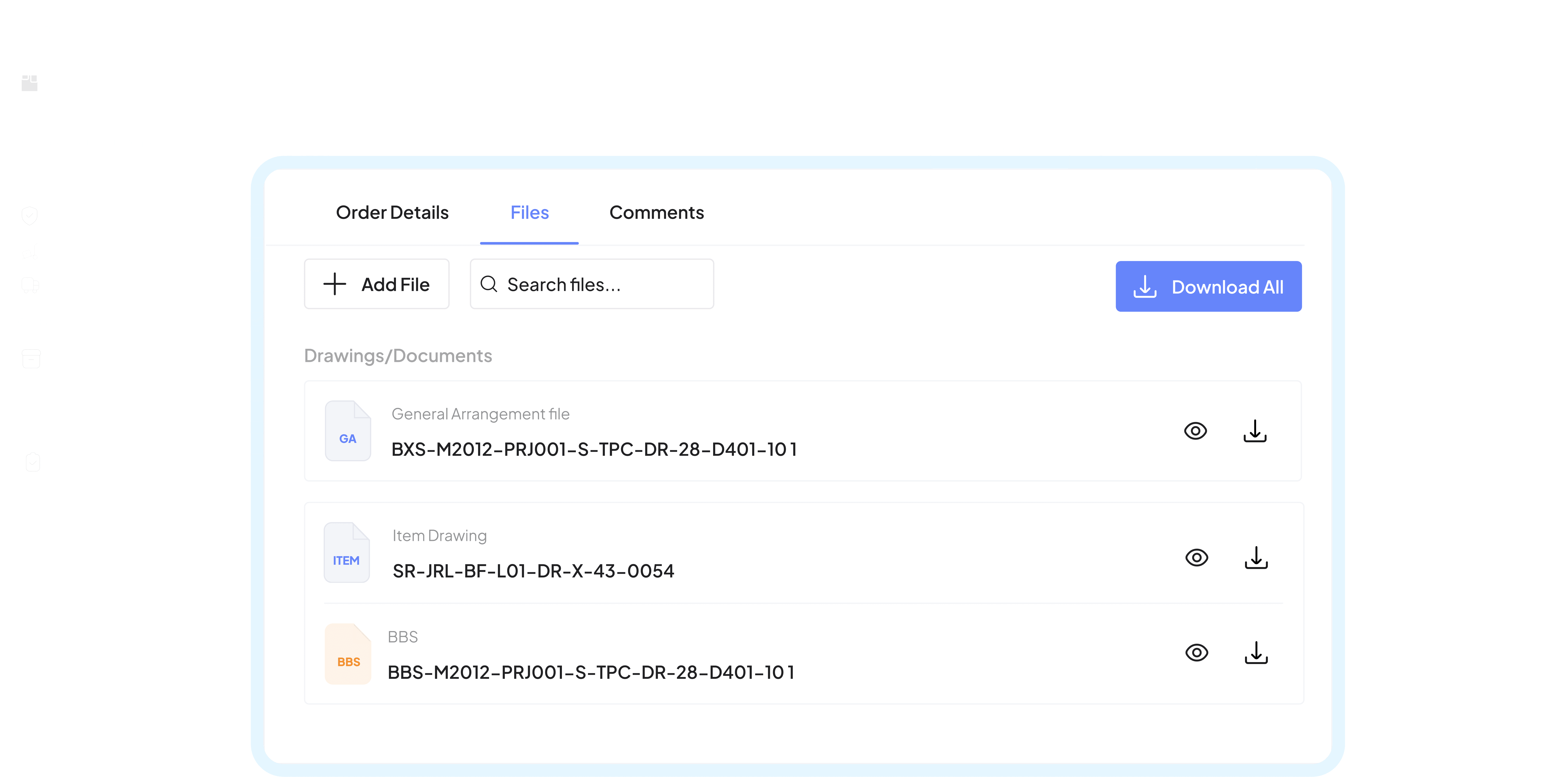

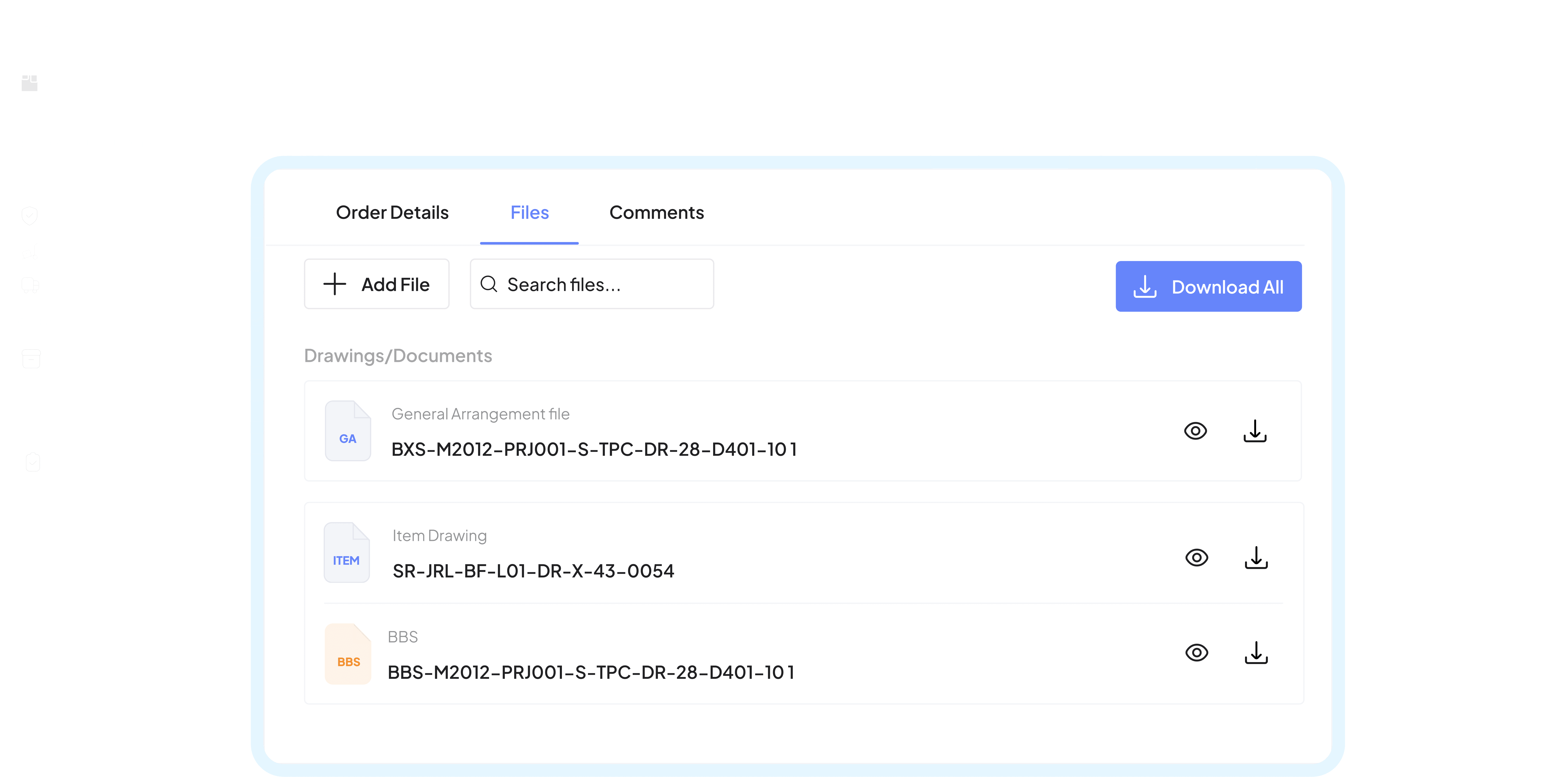

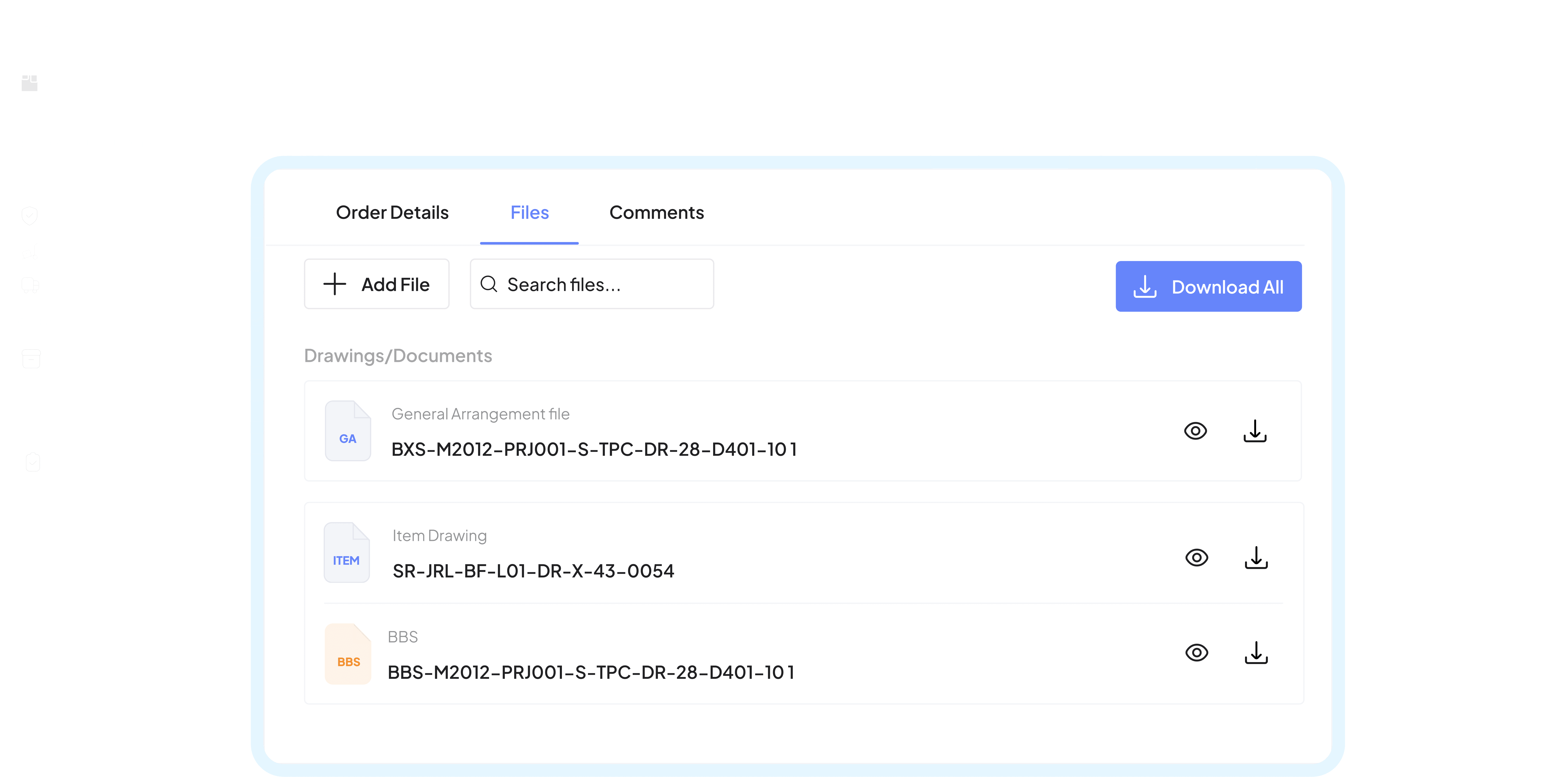

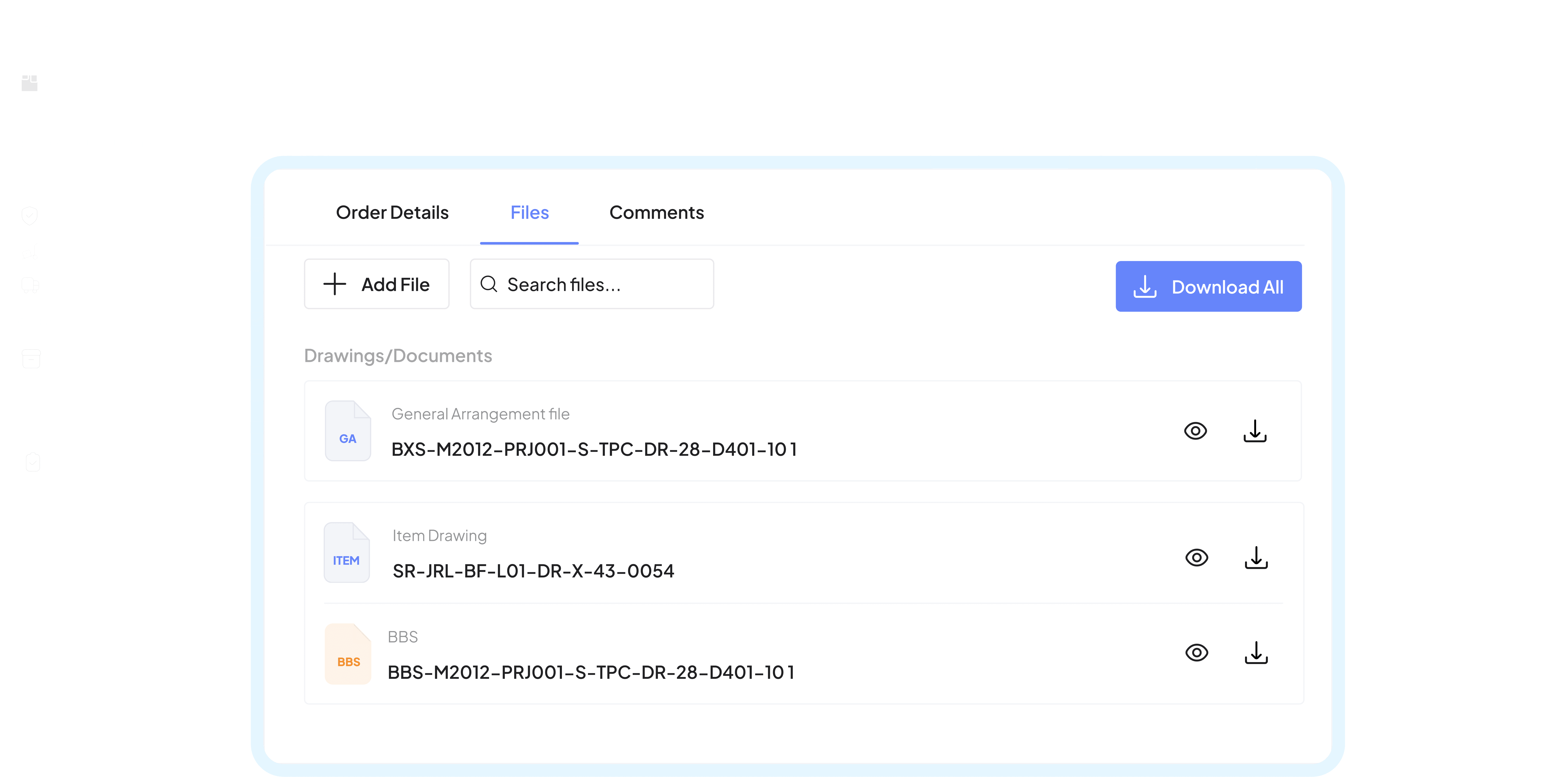

Files & Comments

Easily share information, feedback, and essential documents, fostering seamless collaboration for enhanced productivity.

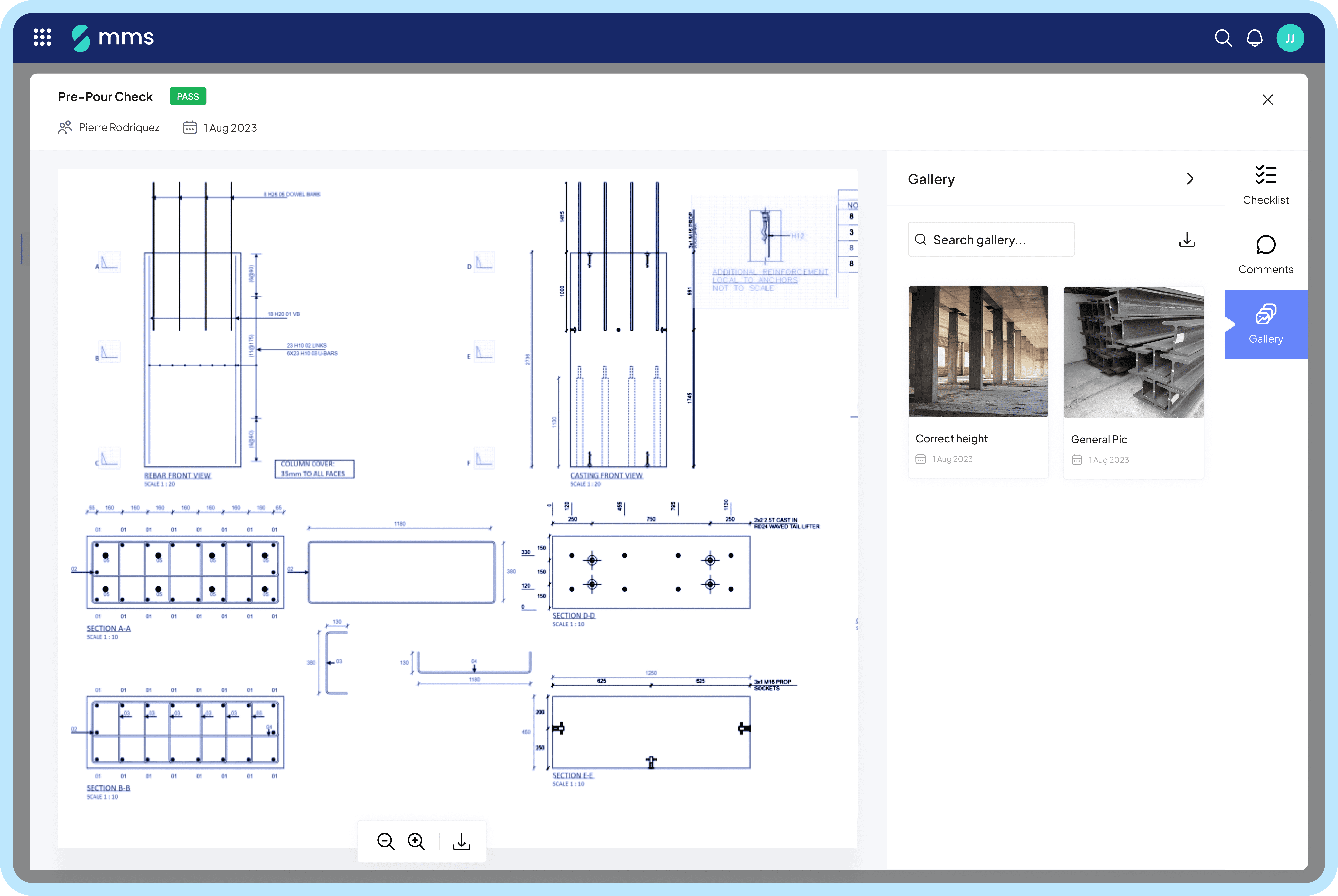

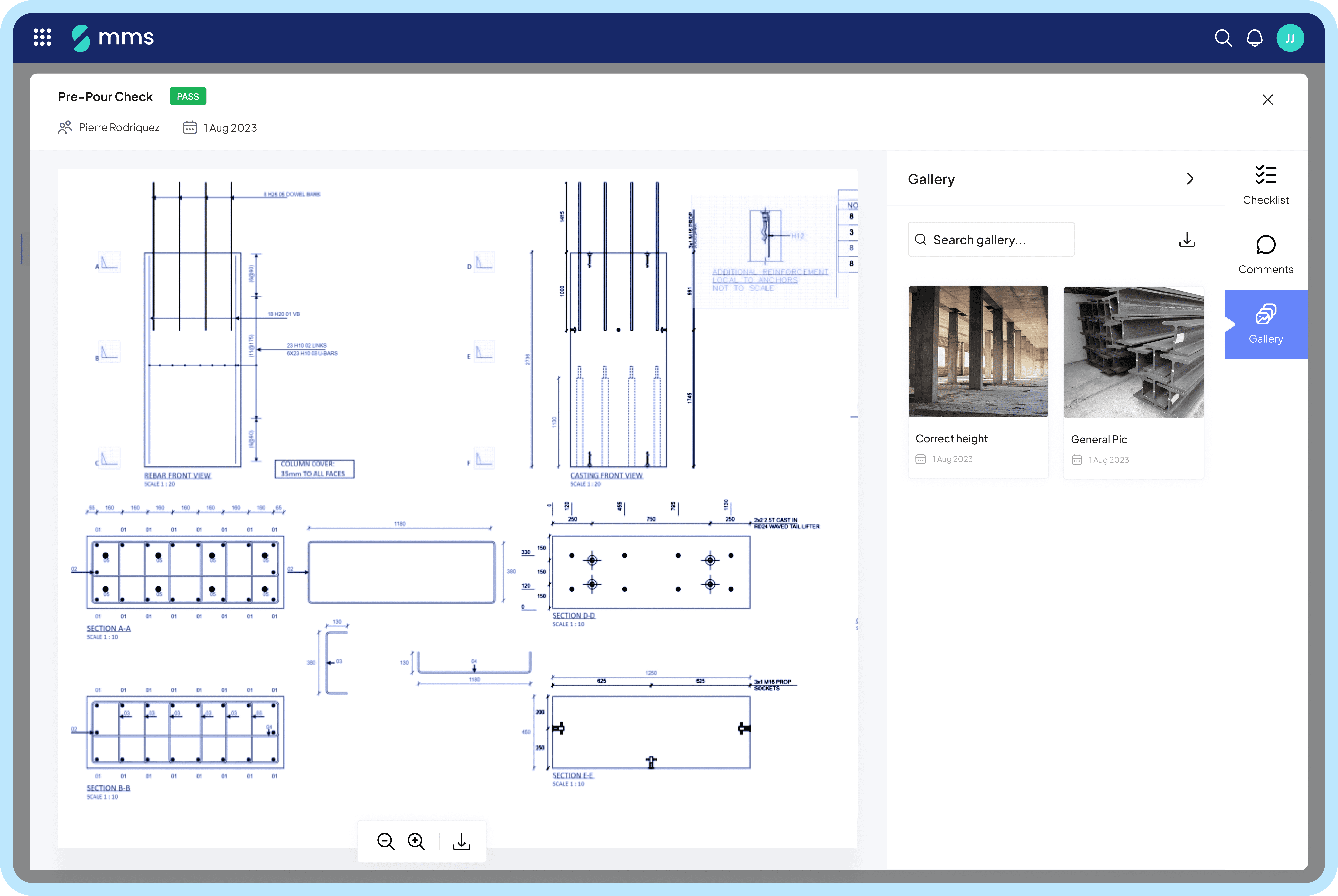

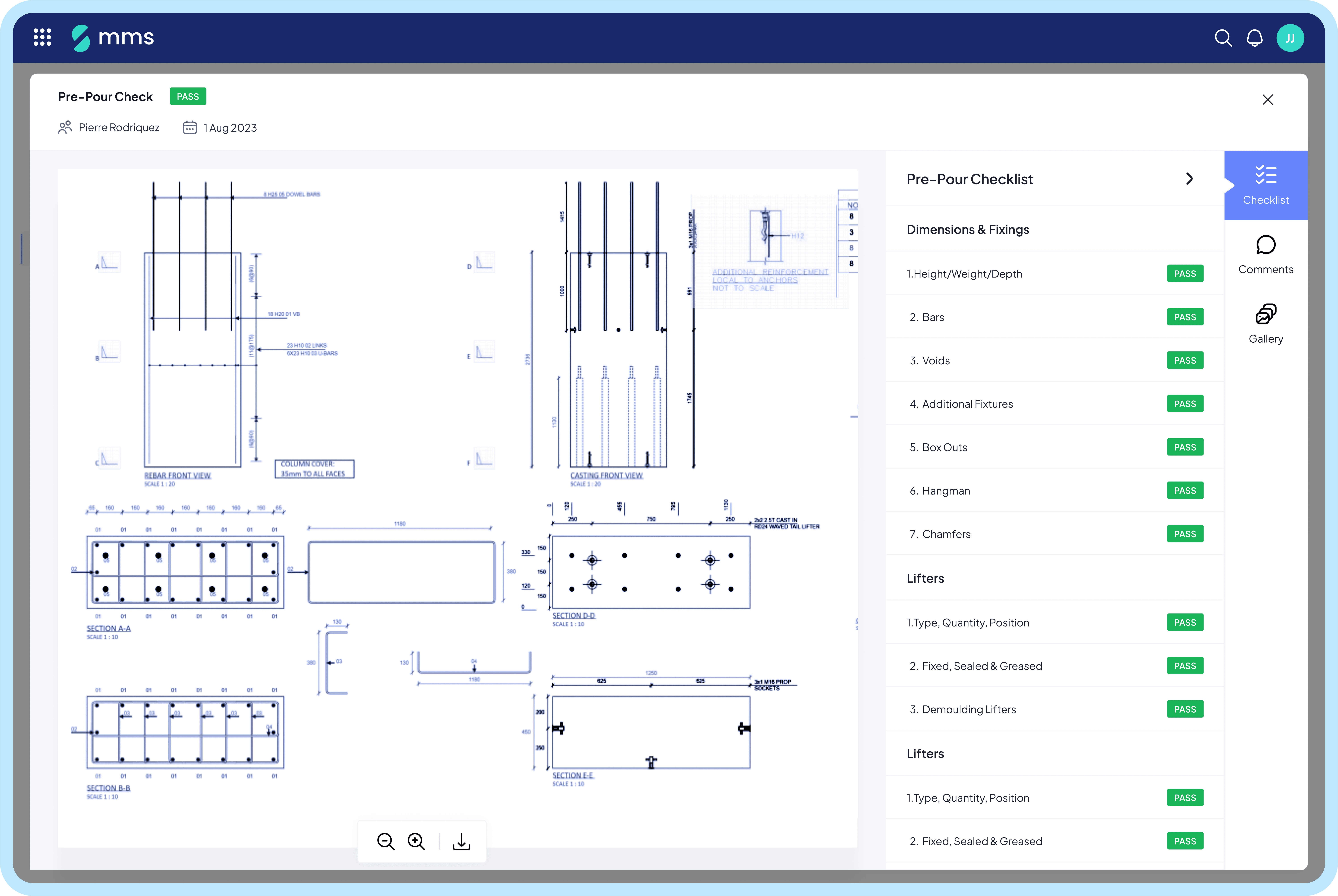

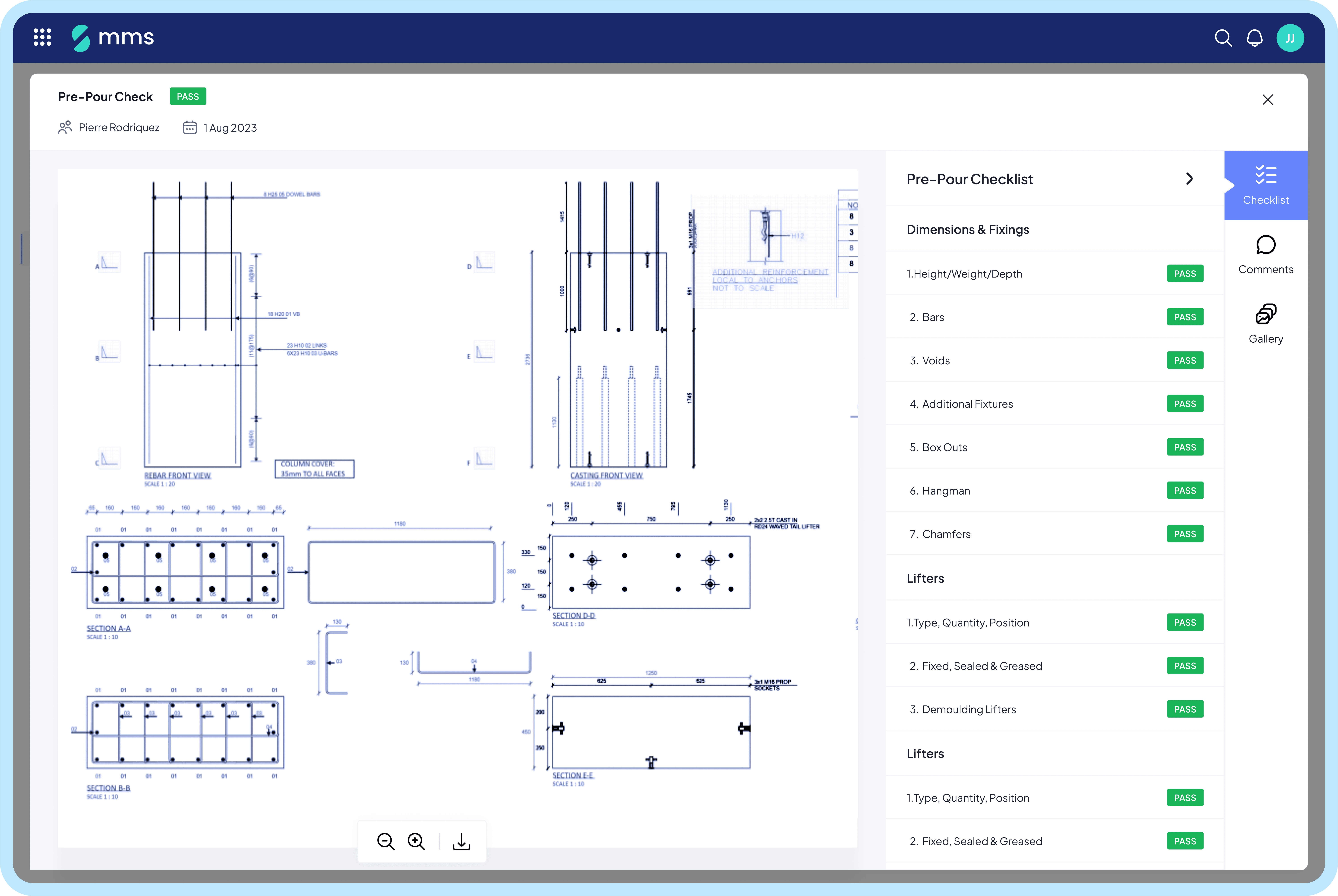

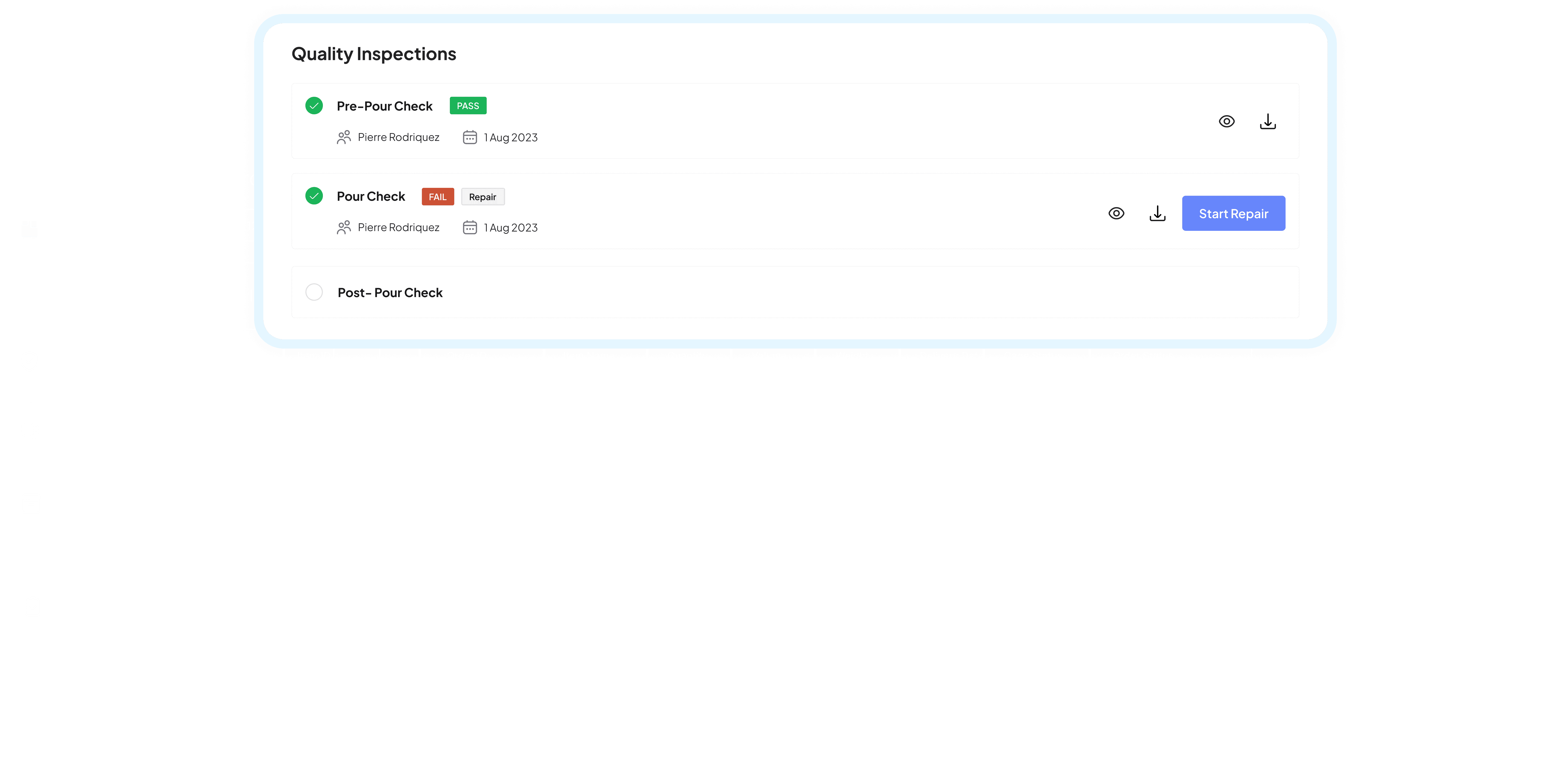

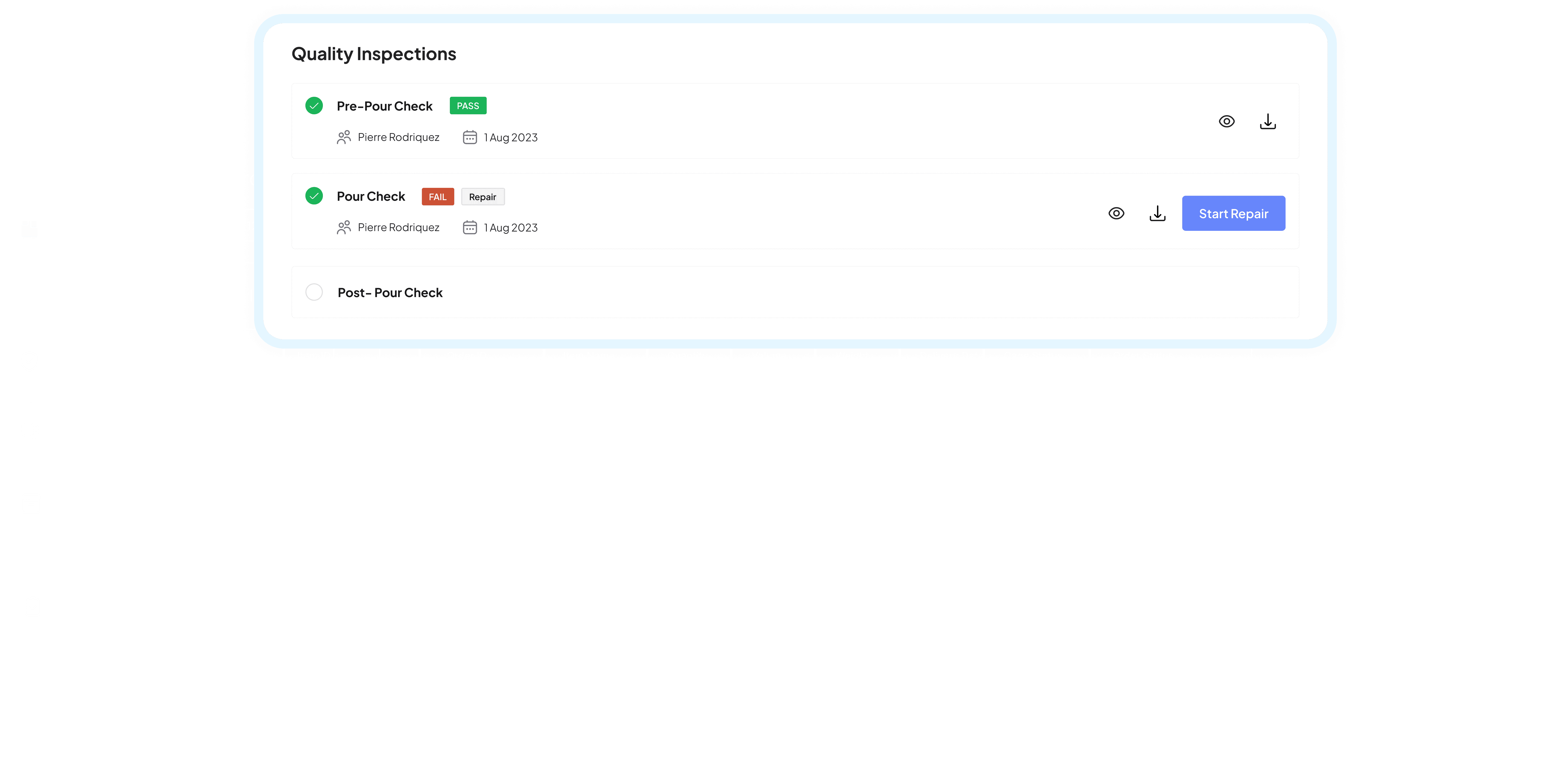

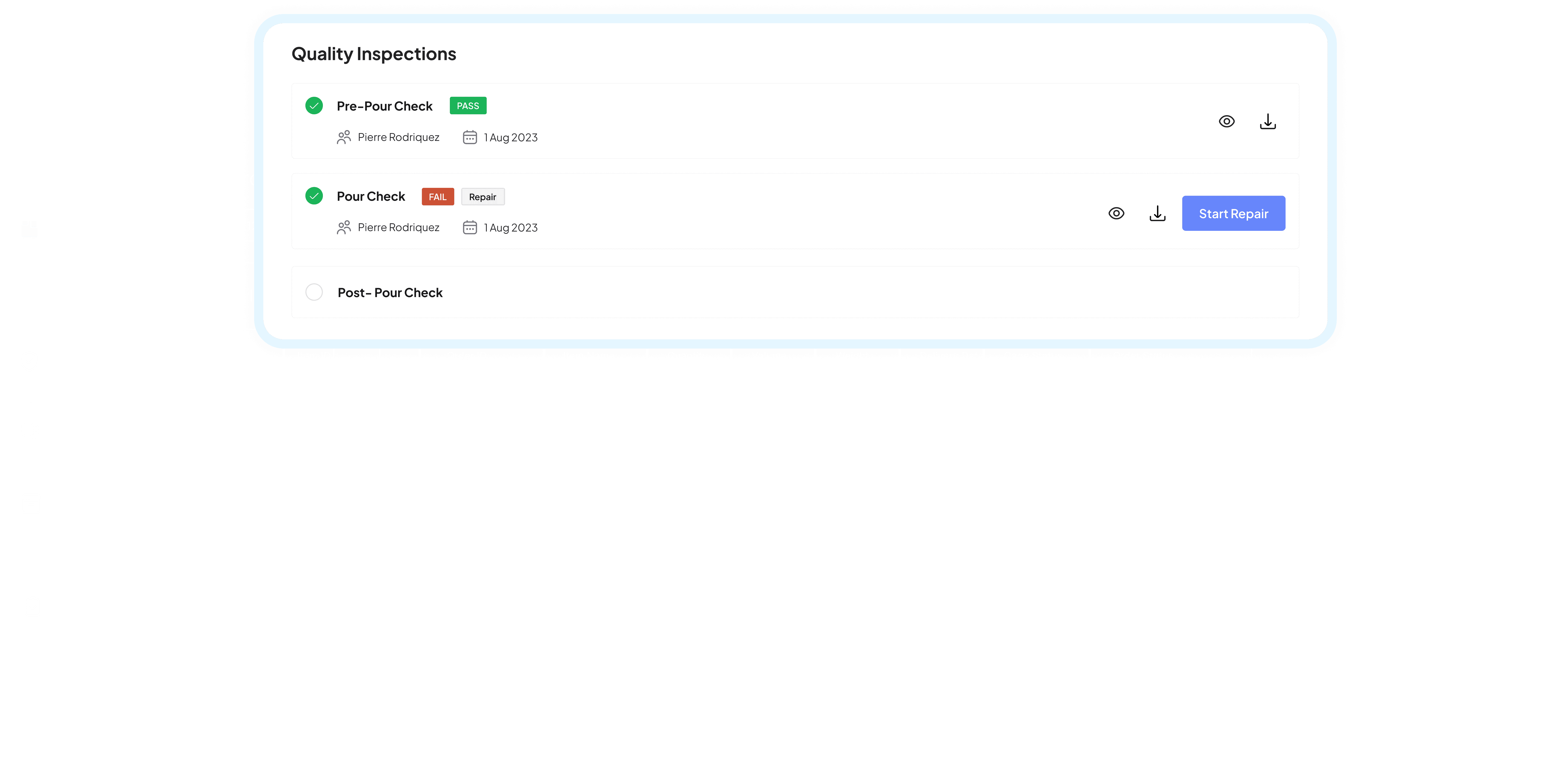

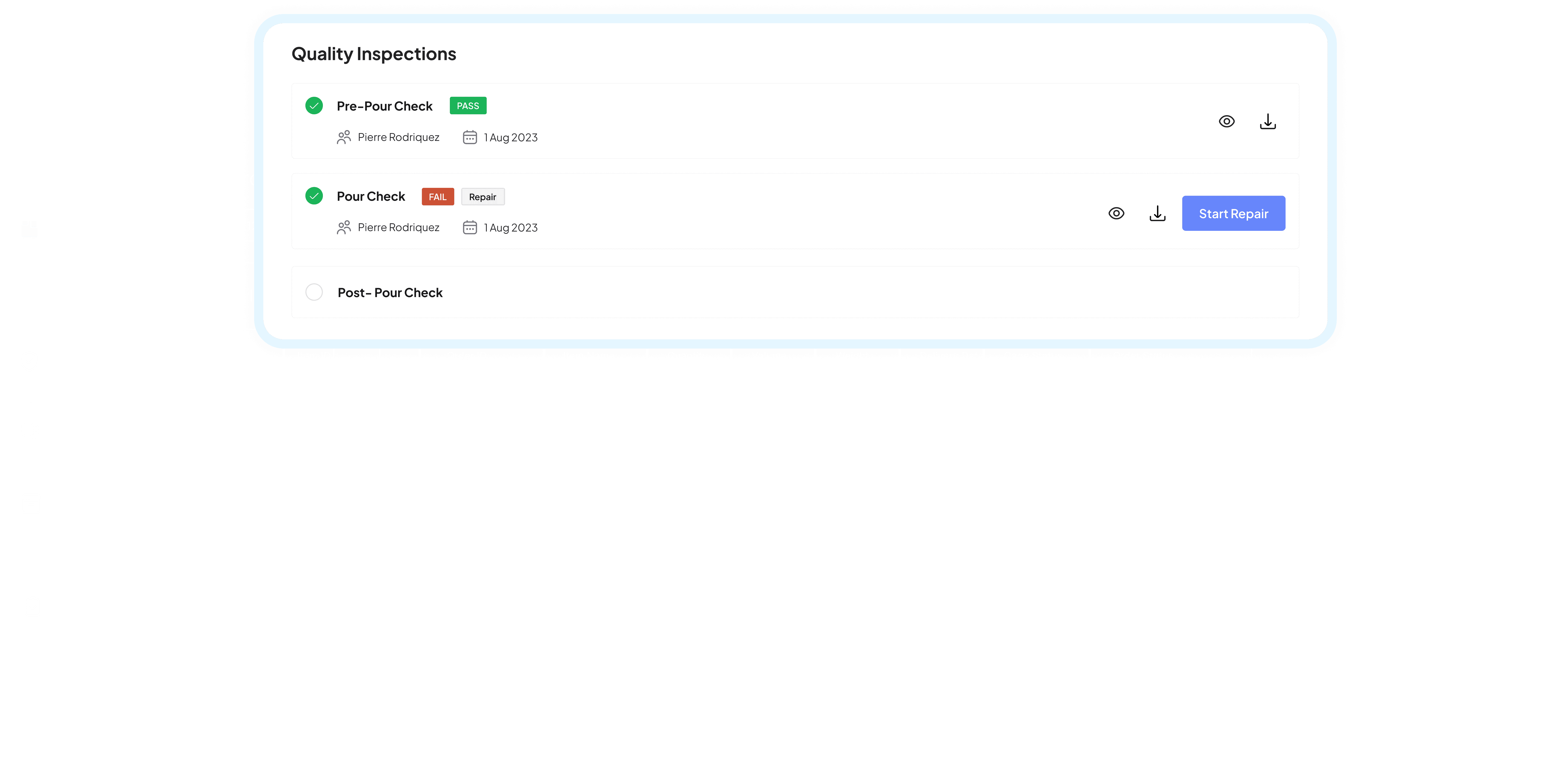

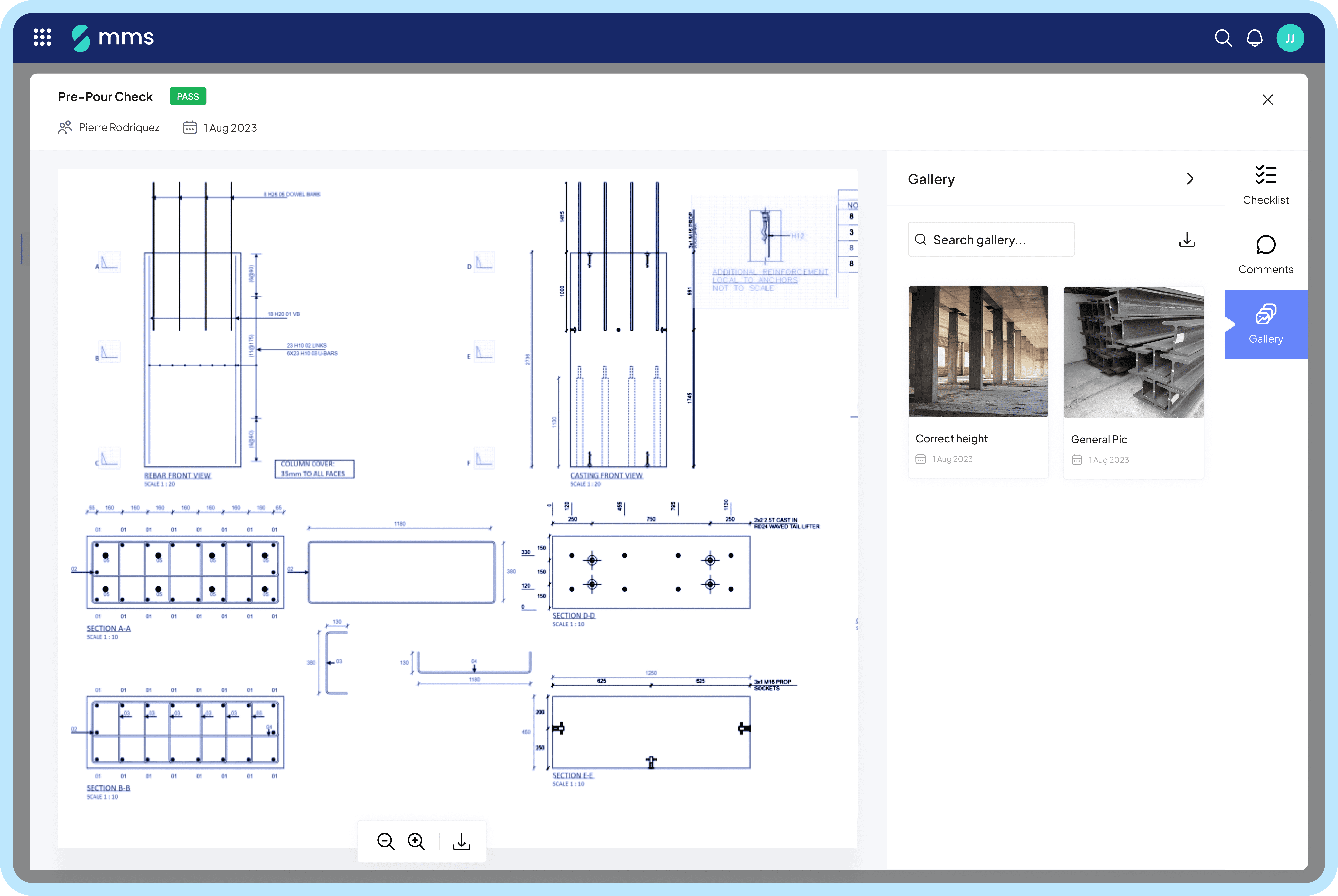

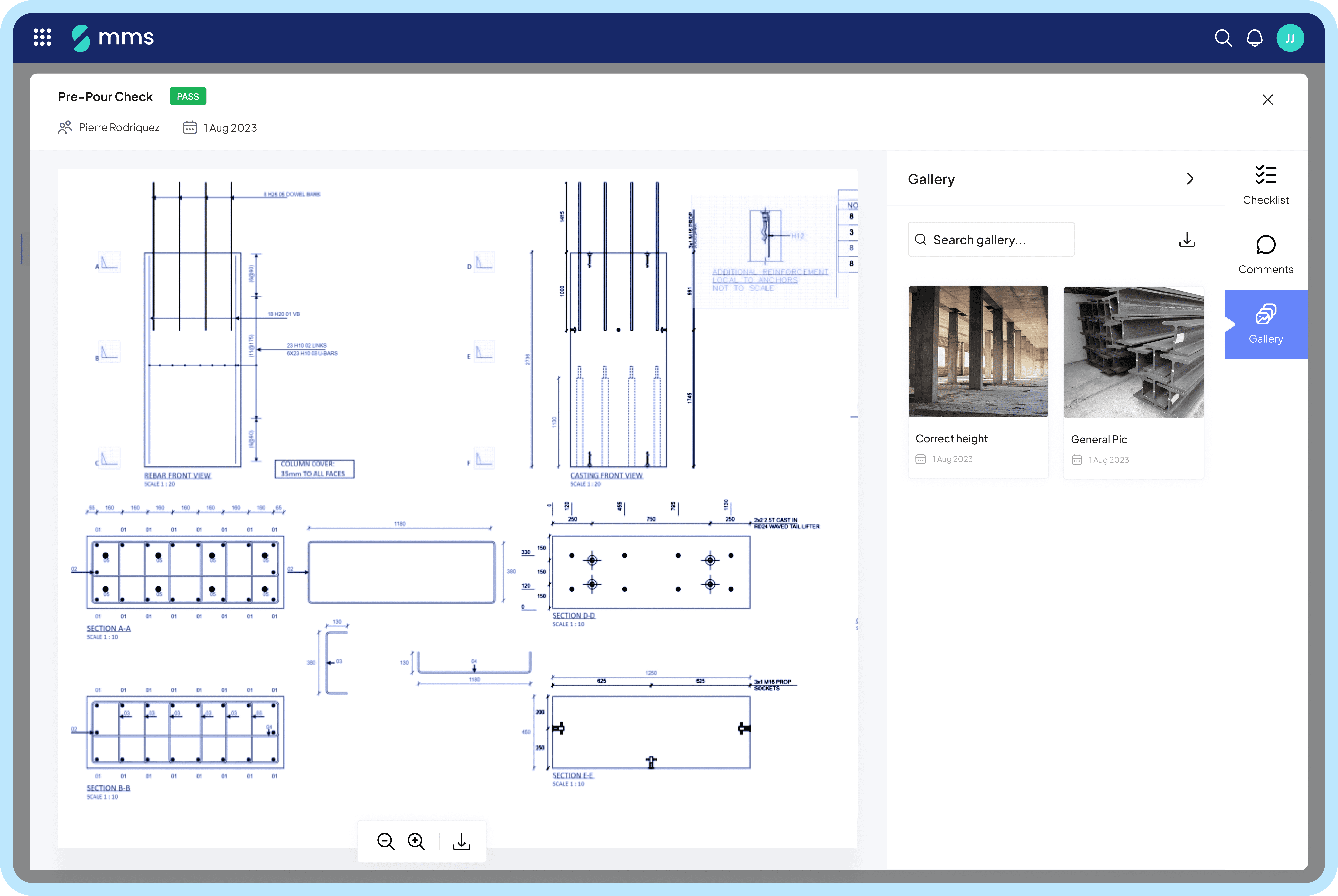

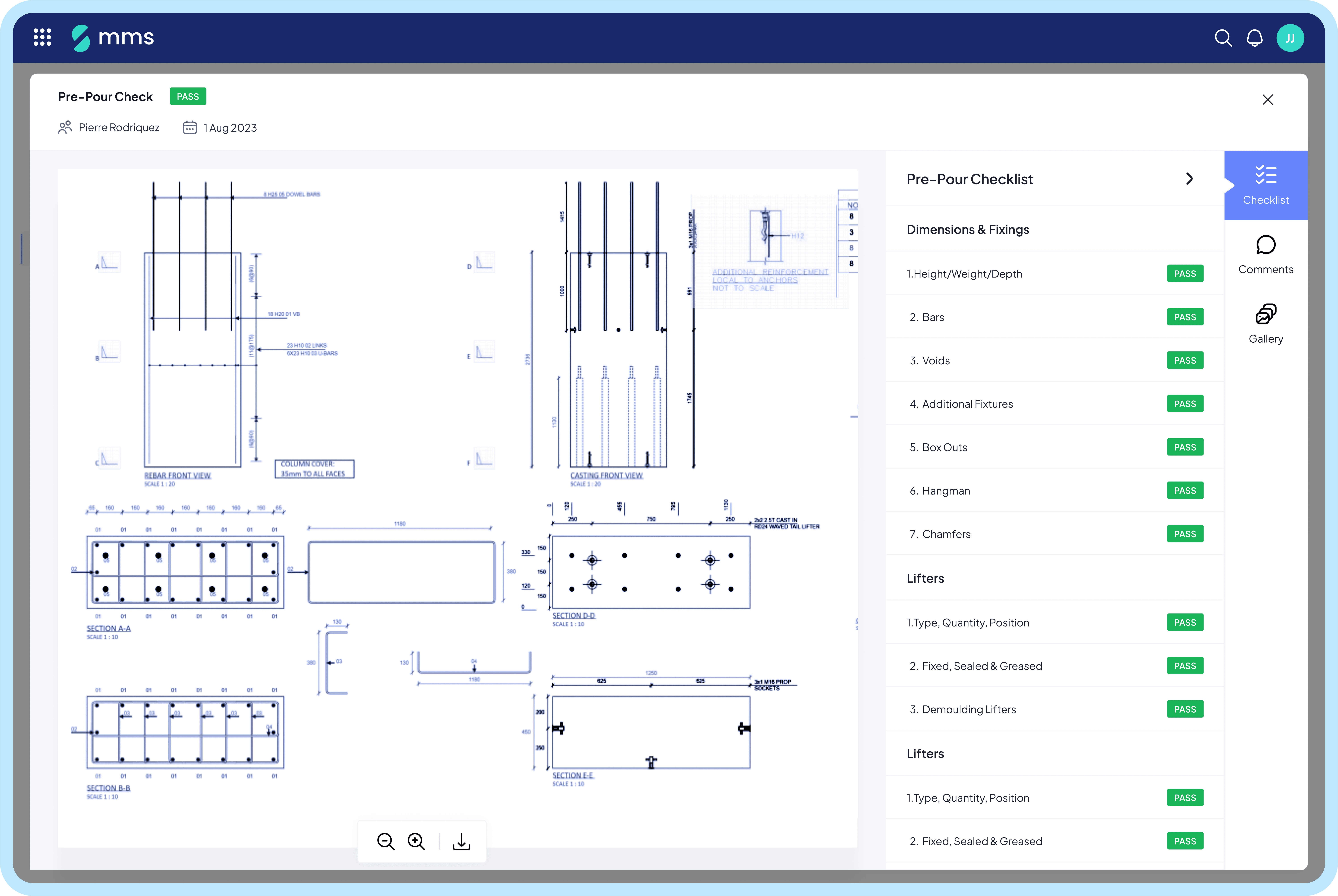

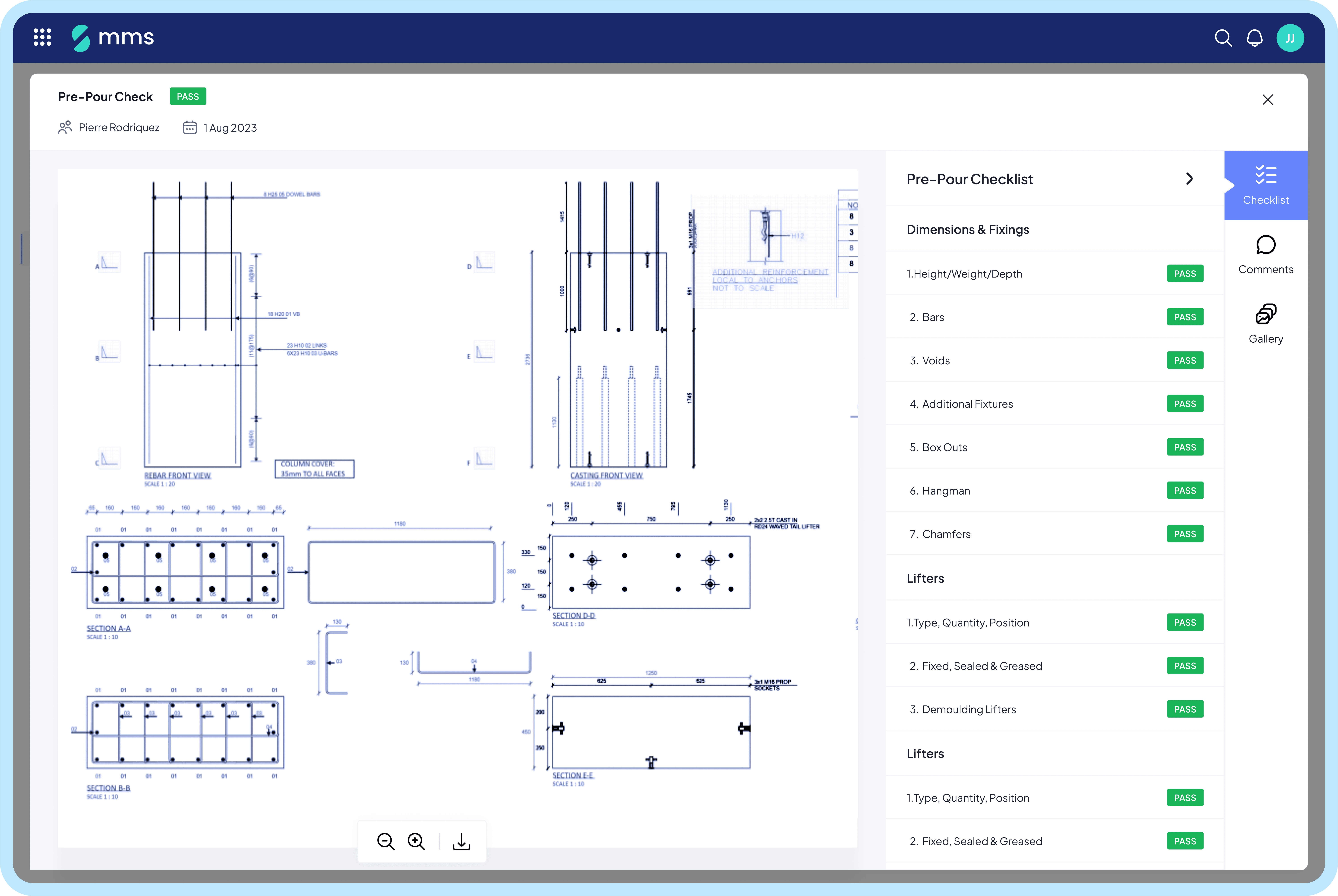

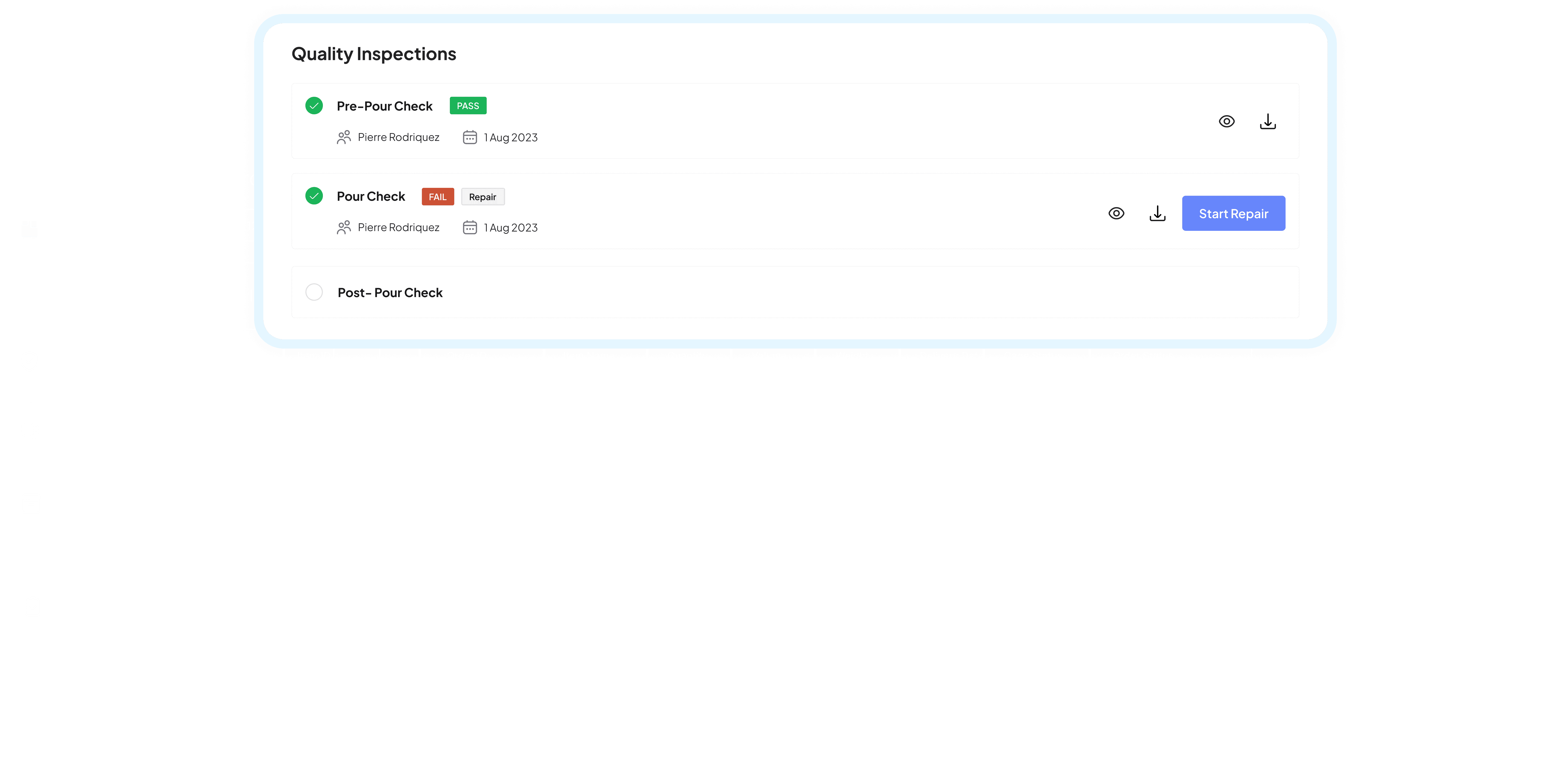

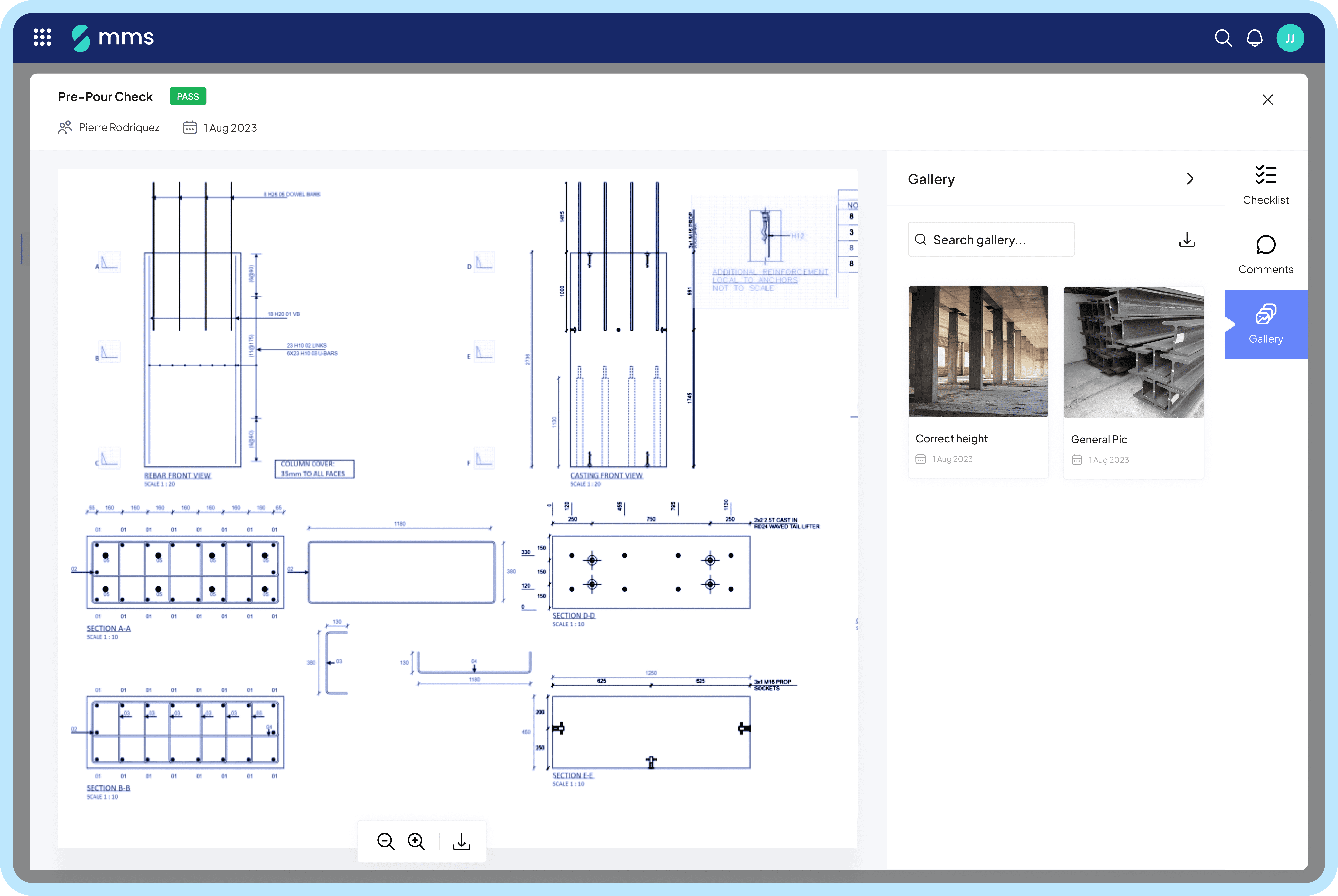

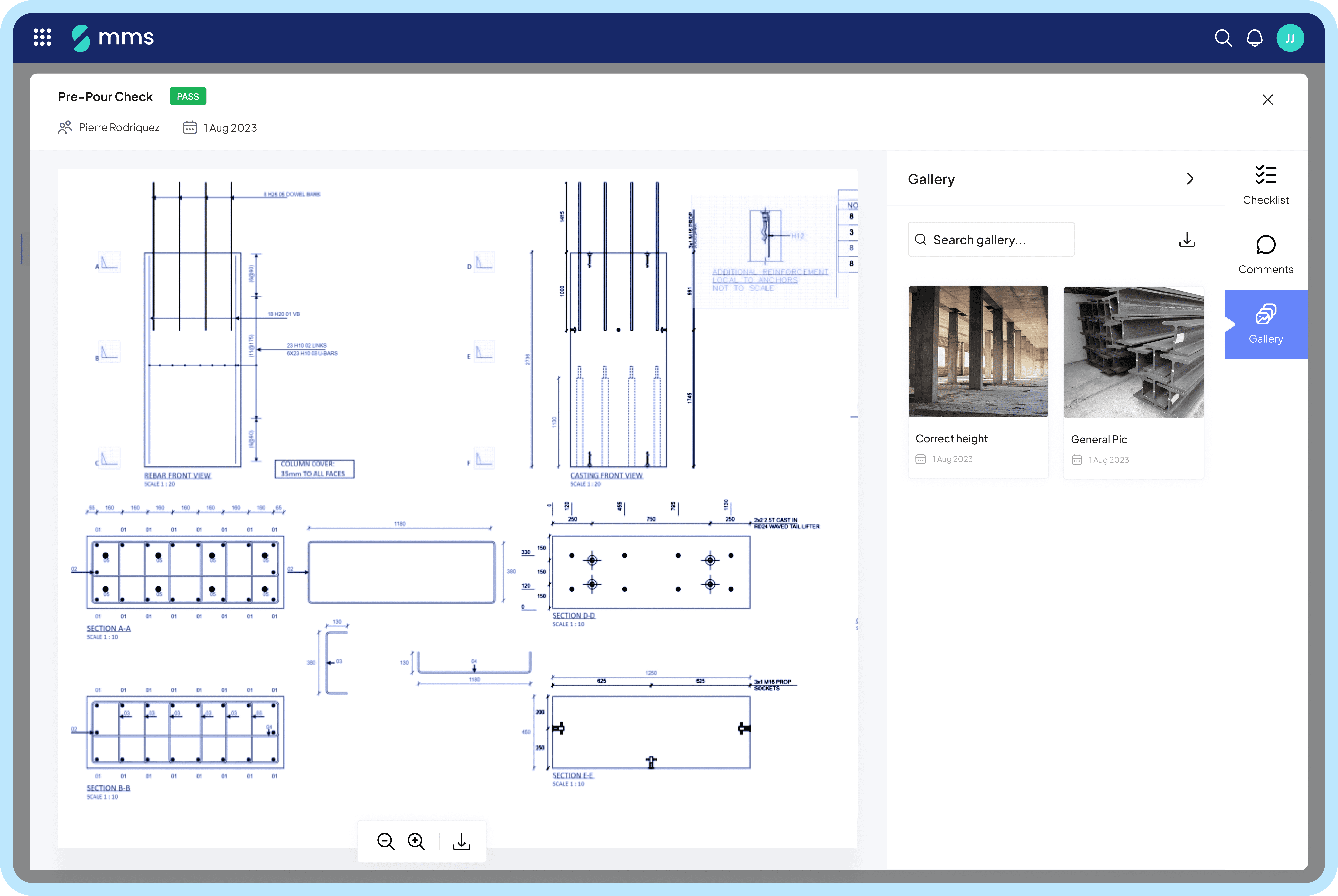

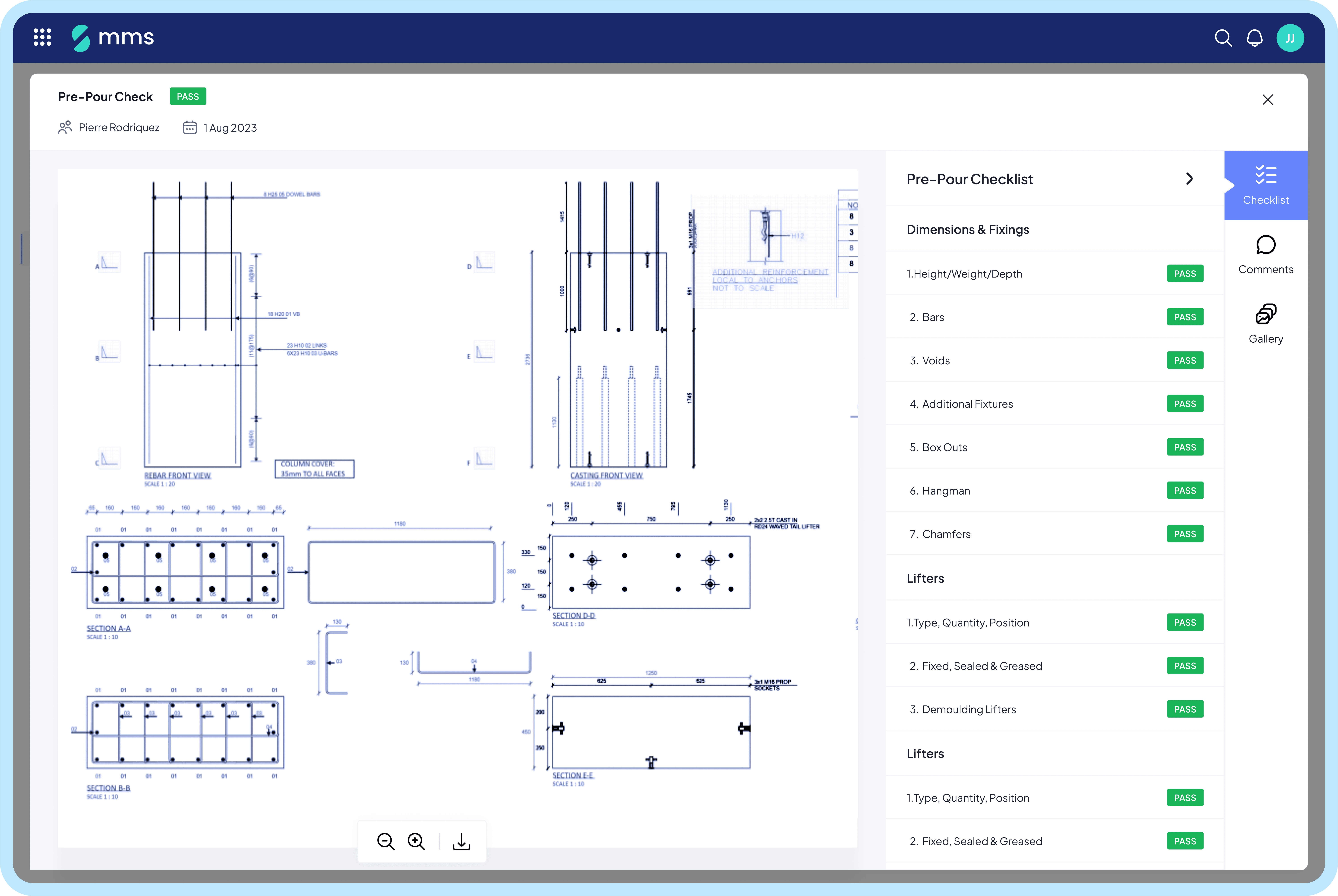

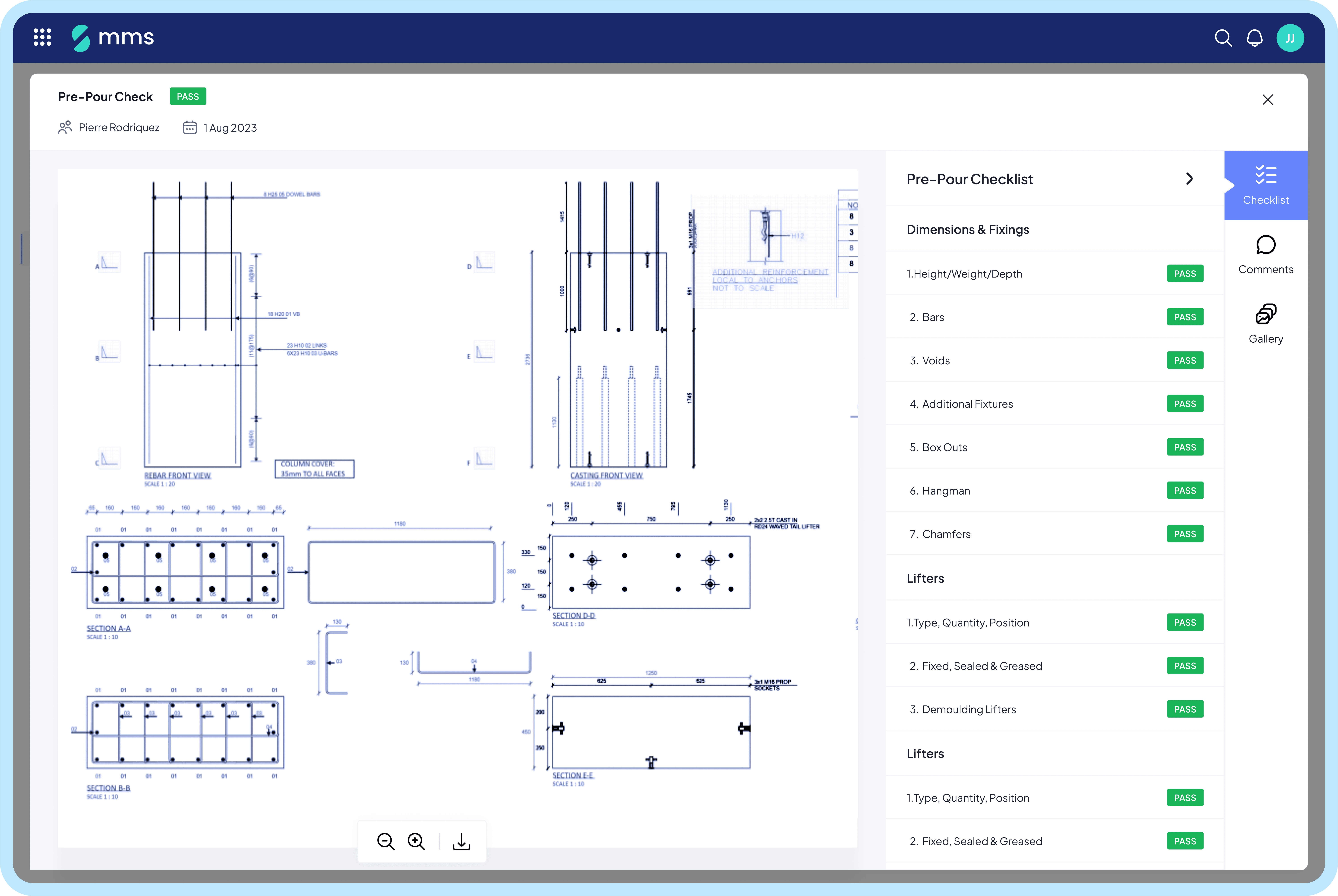

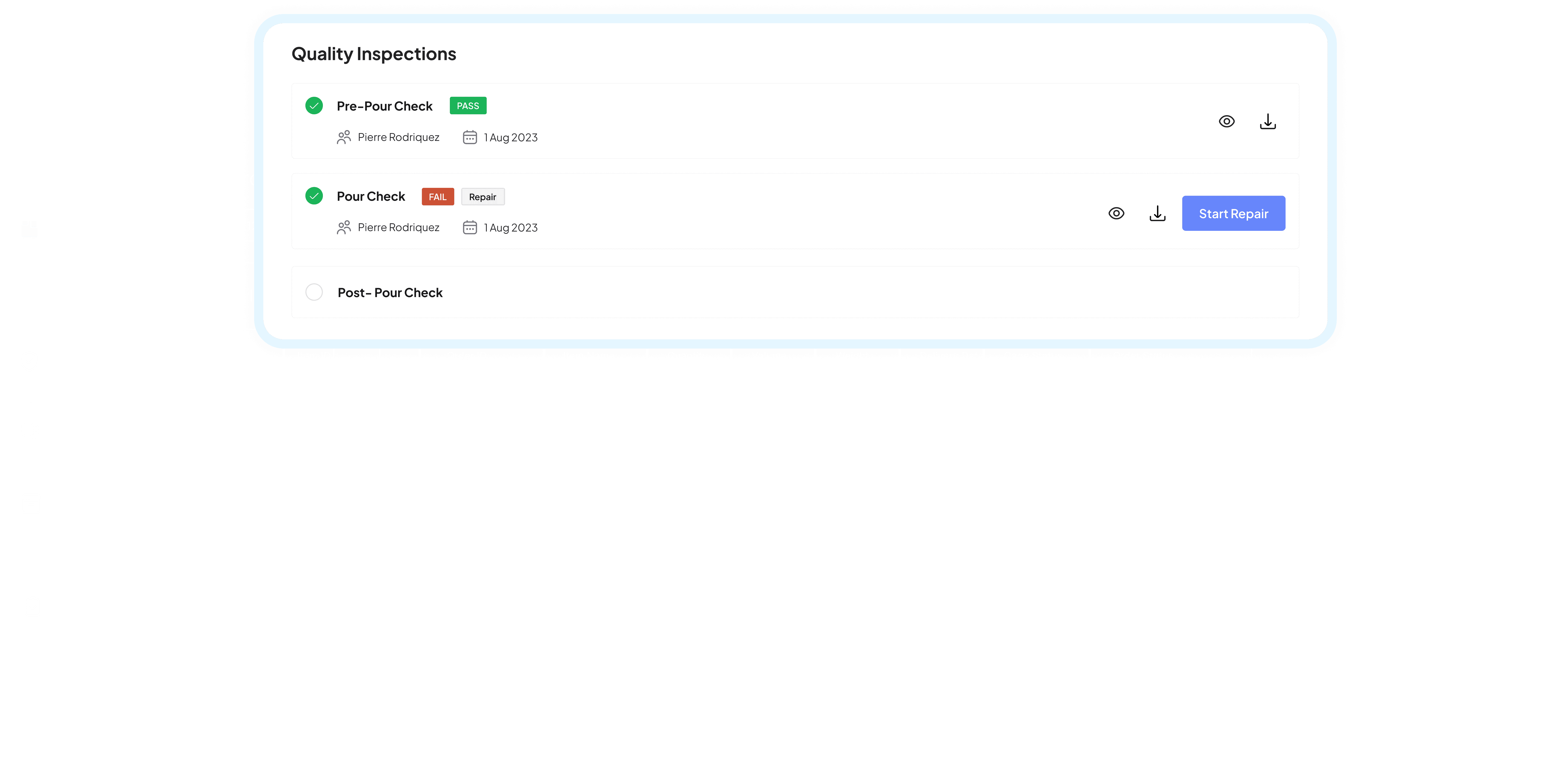

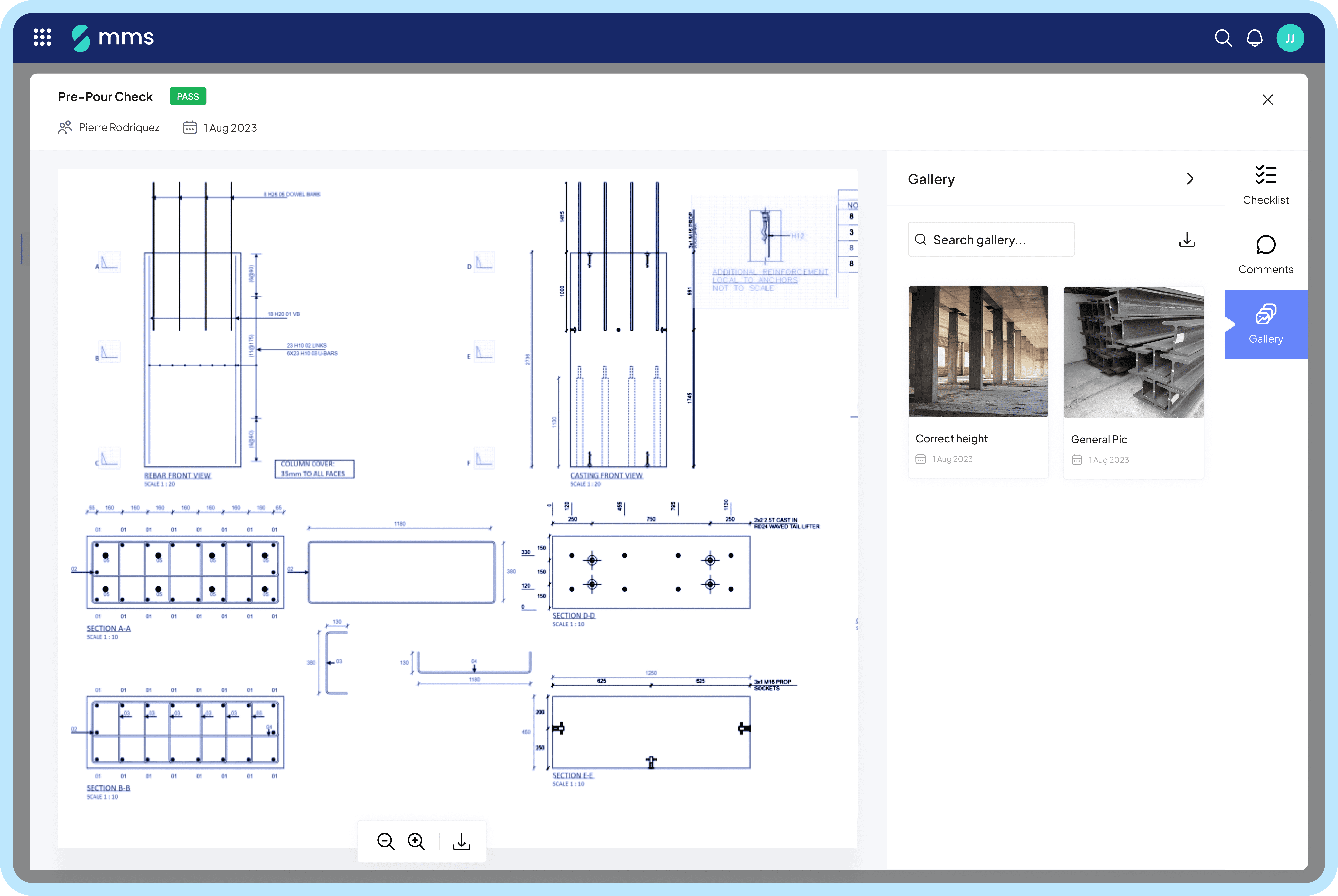

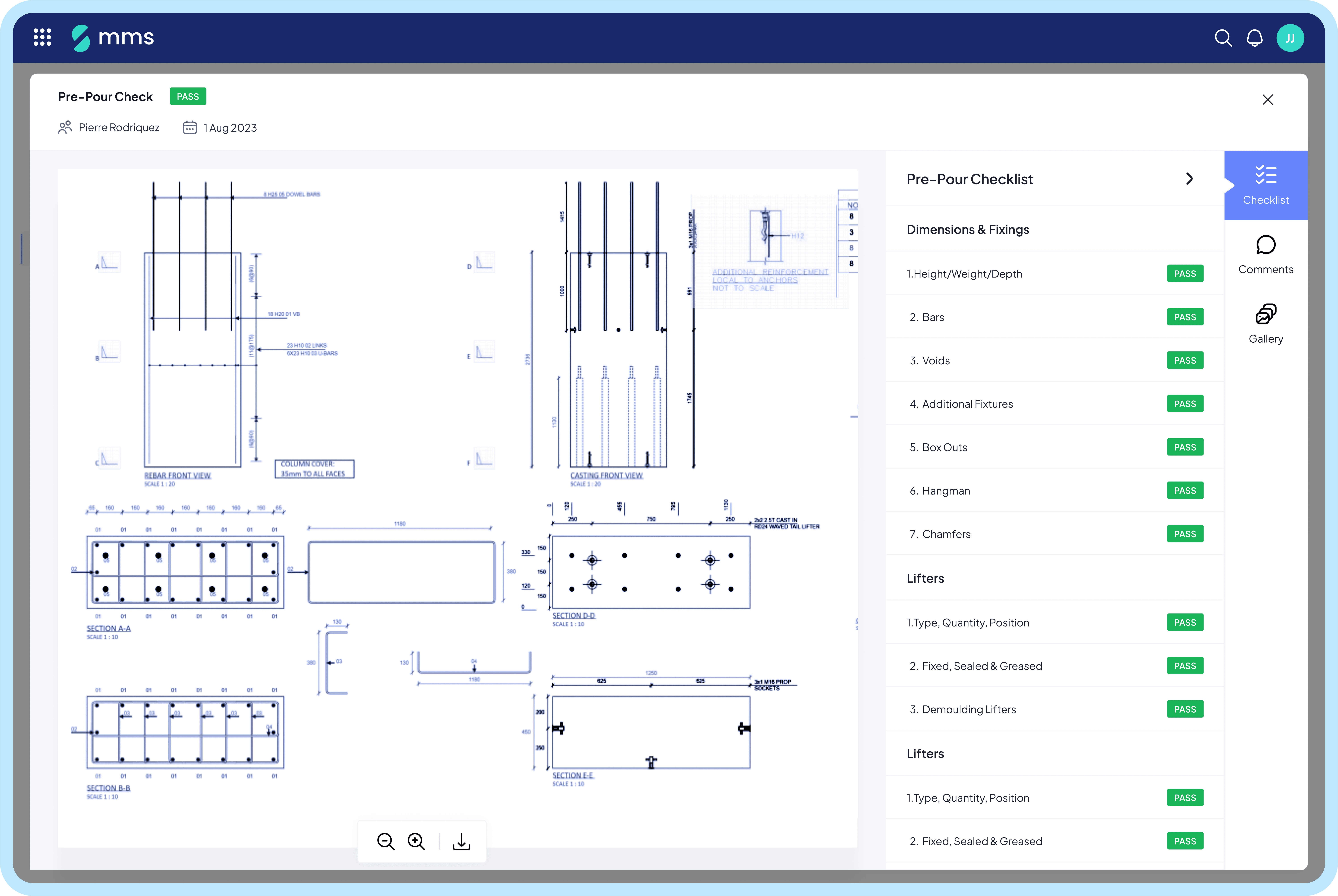

Quality

Track the quality inspection history by checking dates and people involved. Review the questionnaire, and access any additional photos or comments.

UI

03

UI

UI

UI

03

03

03

Dashboard

Dashboard

Dashboard

The dashboard enables users to access real-time data visualizations for each production stage and provides a quick overview of upcoming orders. Users can delve into detailed order descriptions, making informed decisions to approve or reject them.

The dashboard enables users to access real-time data visualizations for each production stage and provides a quick overview of upcoming orders. Users can delve into detailed order descriptions, making informed decisions to approve or reject them.

The dashboard enables users to access real-time data visualizations for each production stage and provides a quick overview of upcoming orders. Users can delve into detailed order descriptions, making informed decisions to approve or reject them.

Order Details

detailed history and current status with precise dates and times. Easily track the evolution of the order, add comments, and download all required files.

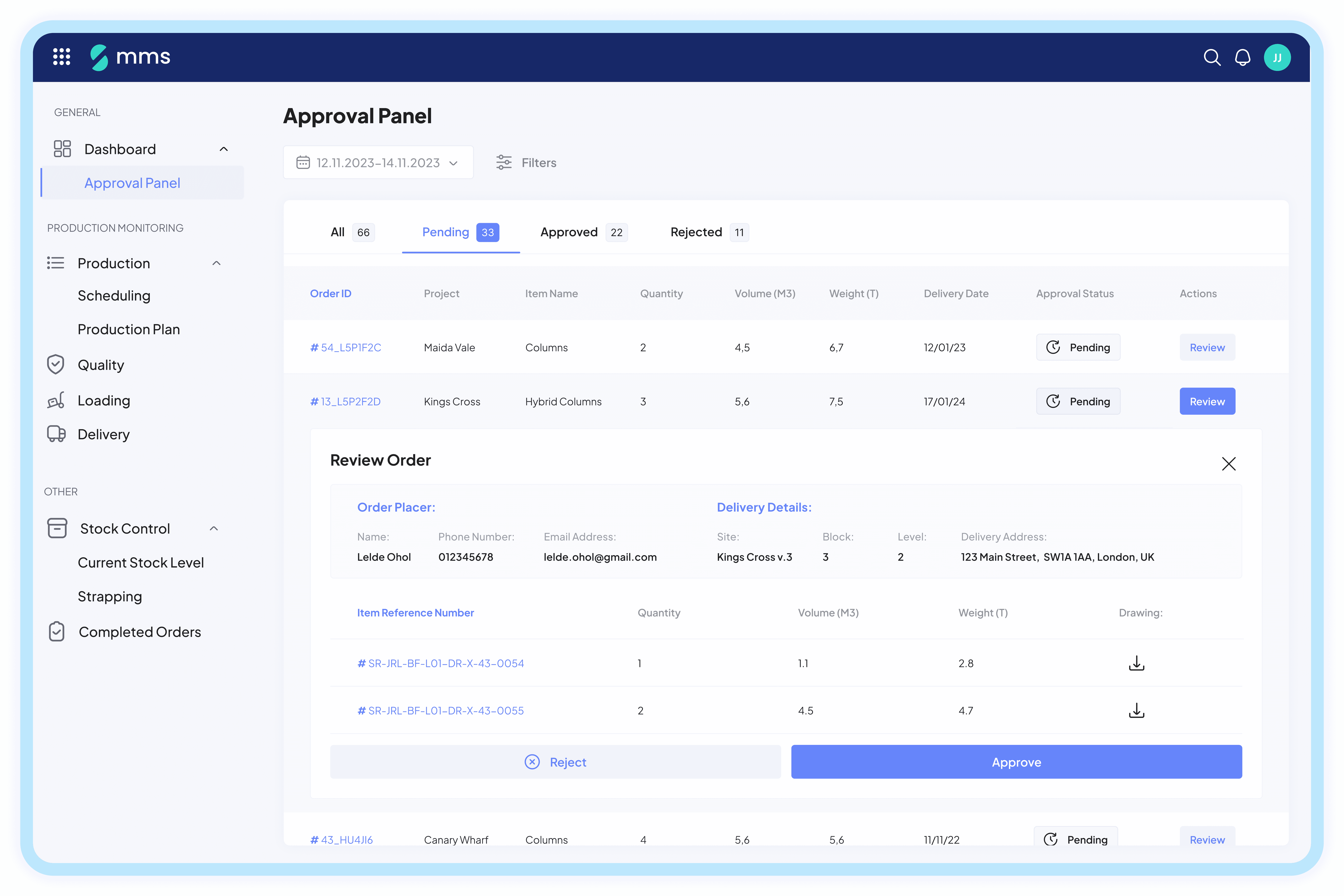

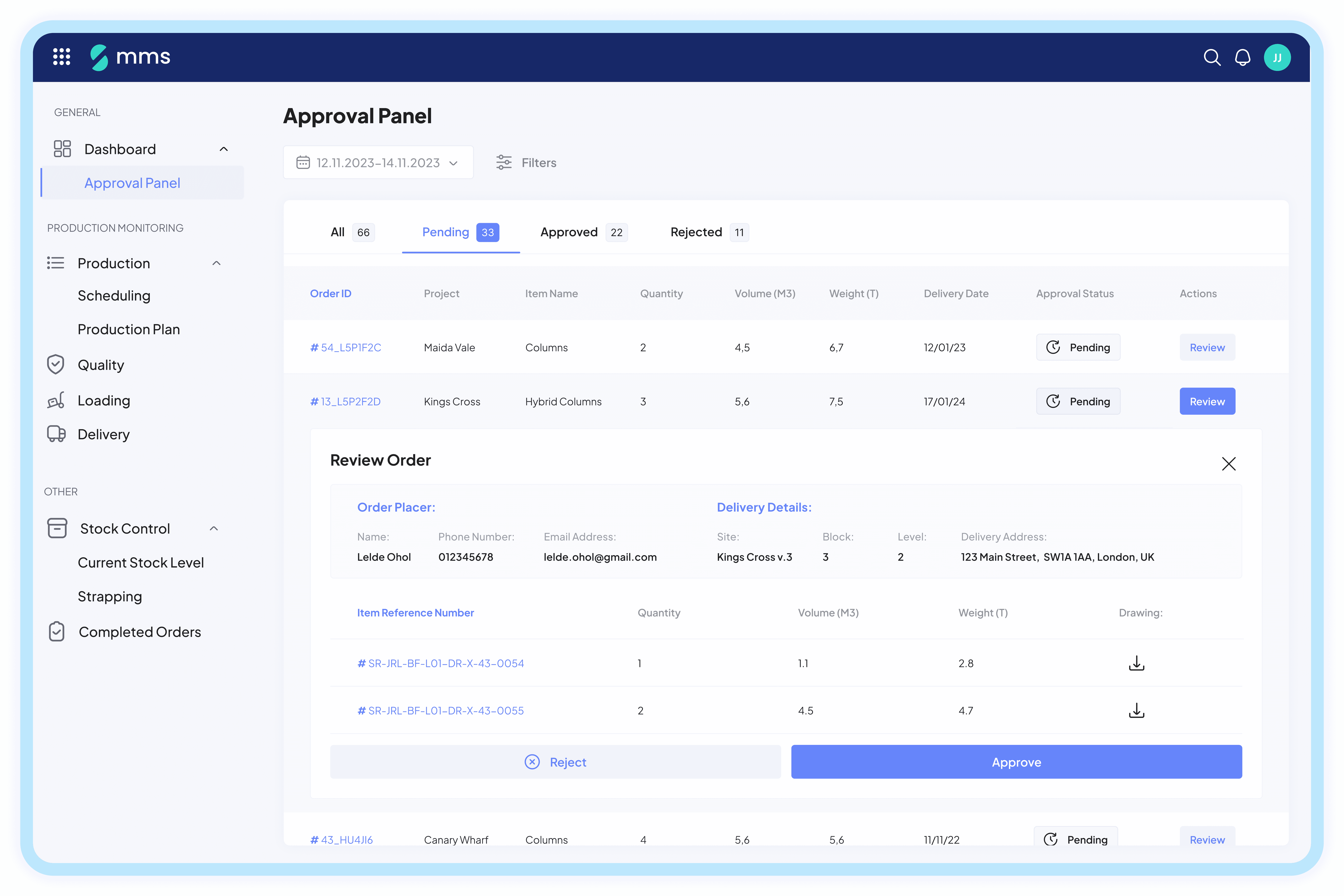

Approvals

Approvals

Approvals

Review upcoming orders, examining the number of items with associated volume and weight values. Additionally, assess delivery dates and reject orders when necessary, providing clear explanations directly to the site manager placing the order.

Review upcoming orders, examining the number of items with associated volume and weight values. Additionally, assess delivery dates and reject orders when necessary, providing clear explanations directly to the site manager placing the order.

Review upcoming orders, examining the number of items with associated volume and weight values. Additionally, assess delivery dates and reject orders when necessary, providing clear explanations directly to the site manager placing the order.

Files & Comments

Easily share information, feedback, and essential documents, fostering seamless collaboration for enhanced productivity.

Quality

Track the quality inspection history by checking dates and people involved. Review the questionnaire, and access any additional photos or comments.

Production Planning

Production Planning

Production Planning

Easily plan your production by dragging and dropping unplanned orders on a calendar, adjusting timelines for optimal use of available capacity. Gain a clear, visual overview of all orders. Plus, conveniently select multiple orders to generate tags and adjust production dates as needed for added flexibility and efficiency.

Easily plan your production by dragging and dropping unplanned orders on a calendar, adjusting timelines for optimal use of available capacity. Gain a clear, visual overview of all orders. Plus, conveniently select multiple orders to generate tags and adjust production dates as needed for added flexibility and efficiency.

Easily plan your production by dragging and dropping unplanned orders on a calendar, adjusting timelines for optimal use of available capacity. Gain a clear, visual overview of all orders. Plus, conveniently select multiple orders to generate tags and adjust production dates as needed for added flexibility and efficiency.

Order Details

detailed history and current status with precise dates and times. Easily track the evolution of the order, add comments, and download all required files.

Files & Comments

Easily share information, feedback, and essential documents, fostering seamless collaboration for enhanced productivity.

Quality

Track the quality inspection history by checking dates and people involved. Review the questionnaire, and access any additional photos or comments.

Order Details

detailed history and current status with precise dates and times. Easily track the evolution of the order, add comments, and download all required files.

Files & Comments

Easily share information, feedback, and essential documents, fostering seamless collaboration for enhanced productivity.

Quality

Track the quality inspection history by checking dates and people involved. Review the questionnaire, and access any additional photos or comments.

View